Tue

30

May

2023

3V3~5V 3.12# OLED 256x64 16-level grayscale module SPI/I2C for Arduino

Sun

19

Feb

2023

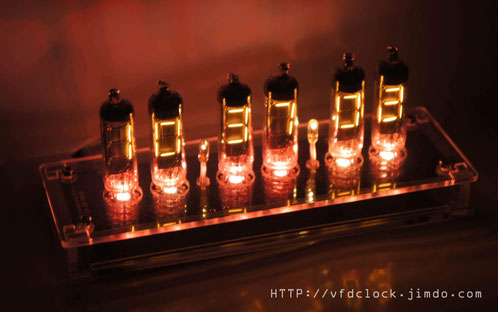

USB powered,IN18 6-tube Clock DIP40 KIT

5V USB Powered-IN-18 6-tube Clock DIY version (DIP40)

Assembly Instructions

V1.0

Tue

11

Jun

2019

USB Powered 6E1P(EM80) 2-tube Magic Eye VU Meter(Stereo Audio Visualizer)-V1.0

Sat

04

May

2019

DIY KIT-5V USB Power-Pluggable IN-18 6-tube NIXIE clock-Assembly Instructions

Sat

12

Nov

2016

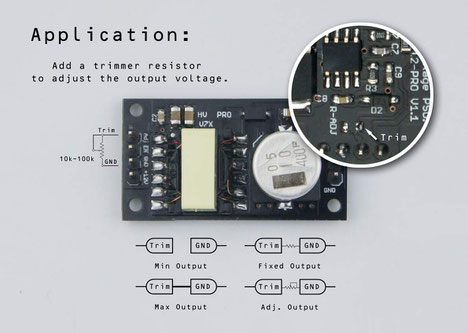

New-[HV12-Pro]-12W-Small Size-12V to 380V(Max) High Efficiency PSU for Audio Application

Sat

17

Sep

2016

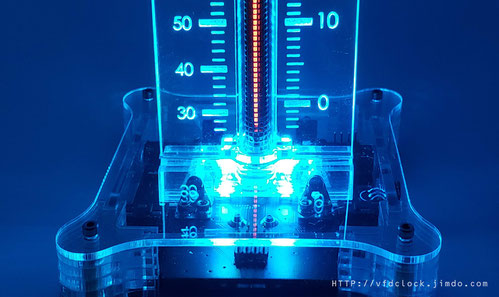

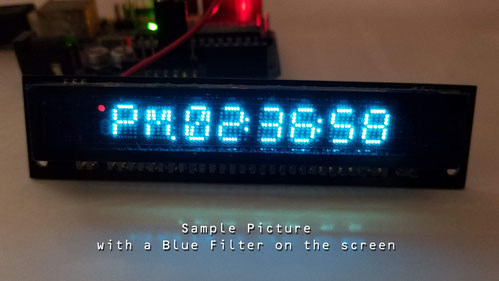

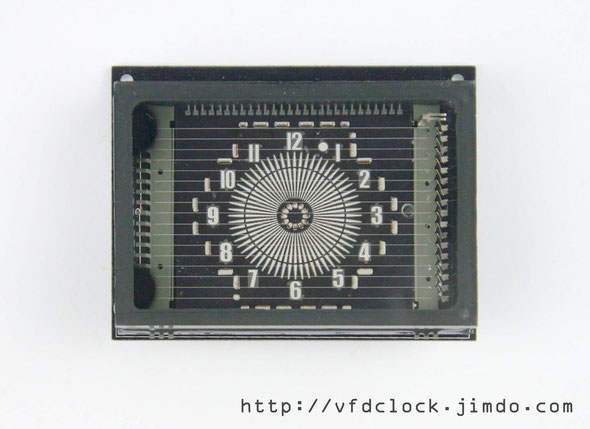

USB Powered VFD48 Analog-style Unique Round VFD Clock Assembly Instructions

Wed

31

Aug

2016

New-USB powered-IN-18 6-tube NIXIE clock with glass tube middle dots

Read More 6 CommentsSat

20

Aug

2016

New-Plug-able IN-14 6-tube NIXIE clock with glass tube middle dots and with AC driving circuit

Read More 1 CommentsTue

26

Jul

2016

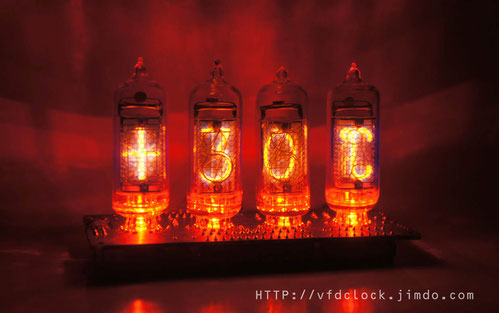

Plug-able USB Powered-Li-poly battery drive-able ,Two-Digit IN-18 NIXIE Tube Clock-Pro.

Sun

24

Apr

2016

Plug-able USB Powered-Li-poly battery drive-able ,Two-Digit IN-14 NIXIE Tube Clock-Pro.

Read More 7 CommentsMon

02

Nov

2015

Z586M Huge Single Digit NIXIE Tube Clock-Pluggable-USB Powered

Fri

23

Oct

2015

433M Wireless GPS Time Station for NIXIE clocks (OLED Version)-V1.0

Read More 2 CommentsSun

26

Jul

2015

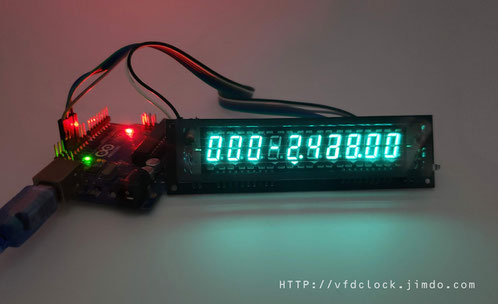

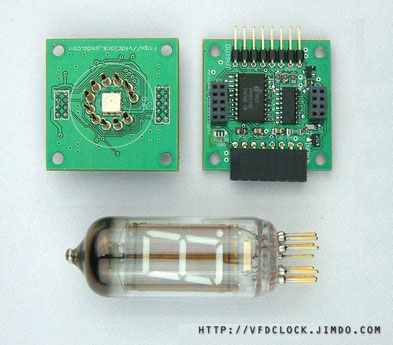

OpenHardware-Pluggable-USB Powered IV-11 Single Digit VFD Tube Clock

Sat

18

Jul

2015

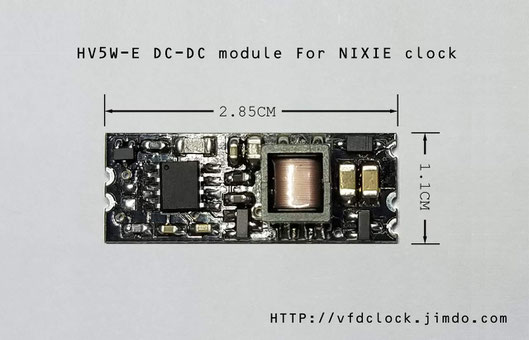

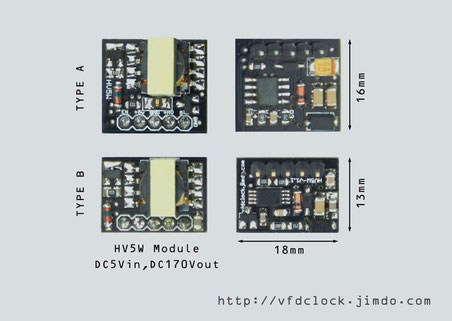

Open Hardware-Highly Optimized-10W-MC34063 based High Voltage power supply module-High efficiency up to 85%-Small Size

Wed

01

Jul

2015

New-HV12W PSU,5V~12V DC in,170V DC out,designed for driving 6-tube IN-18 NIXIE clock-92.6%(Max) high efficiency

Thu

04

Jun

2015

10W-120kHz High Voltage Supply Module-Designed for Audio Amplify Circuit

Mon

25

May

2015

Open Hardware-MC34063 based High Voltage Power Supply Module-10W

Fri

08

May

2015

Open Hardware - GPS Receiver Module for NIXIE/VFD clocks

Thu

15

Jan

2015

Customized the NIXIE PINS from the factory,1U gold plated,Very high quality

Read More 1 CommentsSun

17

Aug

2014

New-HV15W High Voltage NIXIE and Magic Eye Tubes PSU,Power Supply Module V1.0 Std.-MAX1771 Version

Tue

22

Jul

2014

BOE VFD48圆盘时钟正式版-USB Powered BOE VFD48 Analog-style Unique Round VFD Clock With Enclosure

Read MoreSat

19

Jul

2014

USB供电的单管6E2猫眼音量指示器-USB Powered 6E2(EM84) Magic Eye VU Meter(Audio Visualizer)-V1.0

Read MoreSat

19

Jul

2014

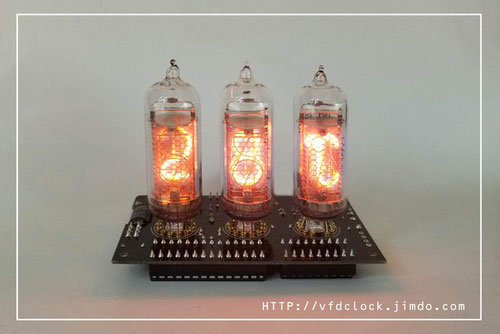

IN-8 and IN-8-2 Single Digit NIXIE Clock V1.0

Wed

02

Apr

2014

IV-11 单管VFD时钟 IV-11 Single Digit VFD CLock V1.0

Wed

02

Apr

2014

IN-12A/B 单管辉光时钟,IN-12A/B Single Digit NIXIE Clock V1.0

NIXIE CLOCK DIY

NIXIE CLOCK DIY