Tue

30

May

2023

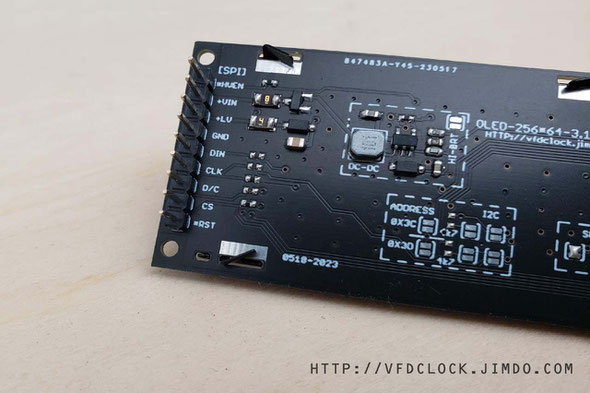

3V3~5V 3.12# OLED 256x64 16-level grayscale module SPI/I2C for Arduino

Sun

19

Feb

2023

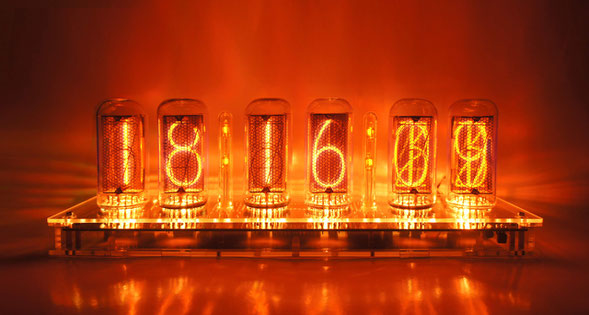

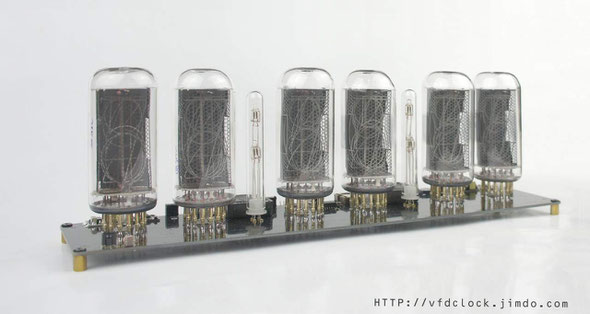

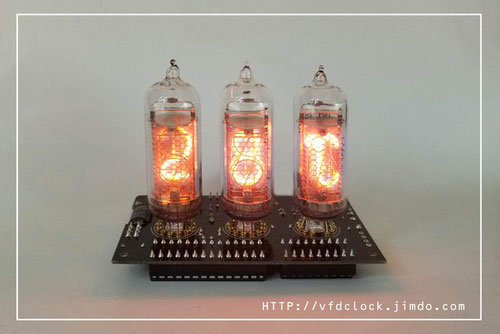

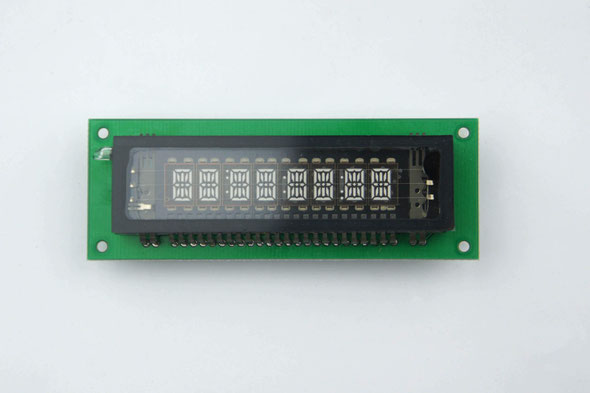

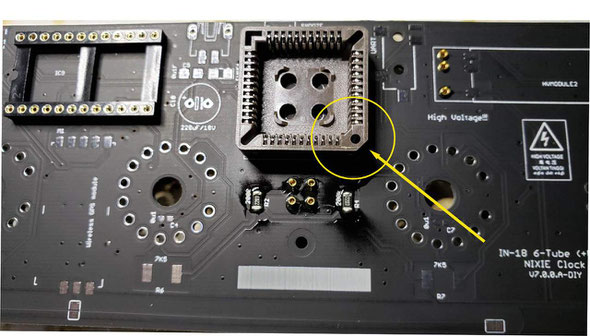

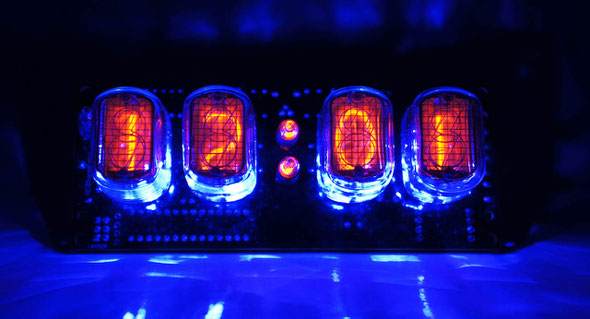

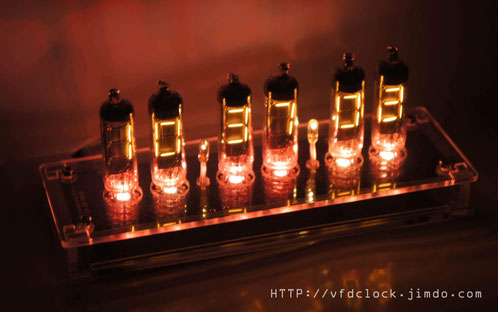

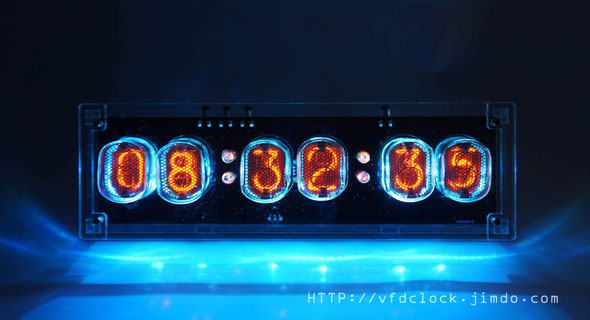

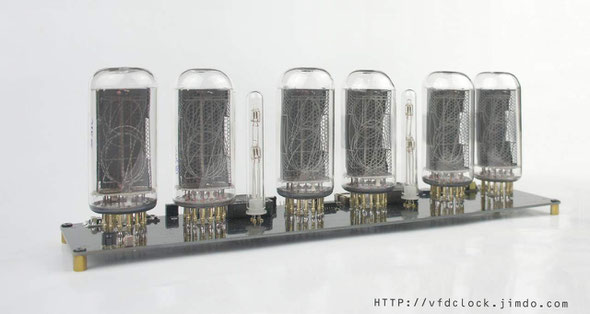

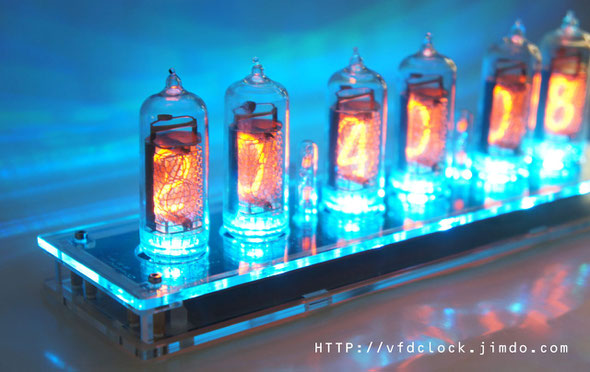

USB powered,IN18 6-tube Clock DIP40 KIT

5V USB Powered-IN-18 6-tube Clock DIY version (DIP40)

Assembly Instructions

V1.0

Tue

11

Jun

2019

USB Powered 6E1P(EM80) 2-tube Magic Eye VU Meter(Stereo Audio Visualizer)-V1.0

Sat

04

May

2019

DIY KIT-5V USB Power-Pluggable IN-18 6-tube NIXIE clock-Assembly Instructions

Sat

12

Nov

2016

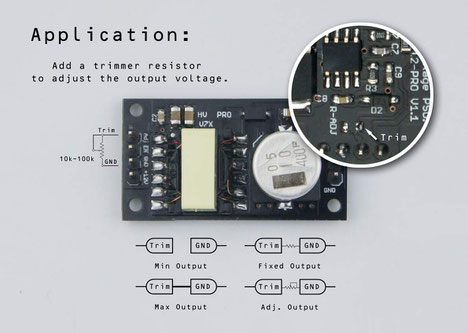

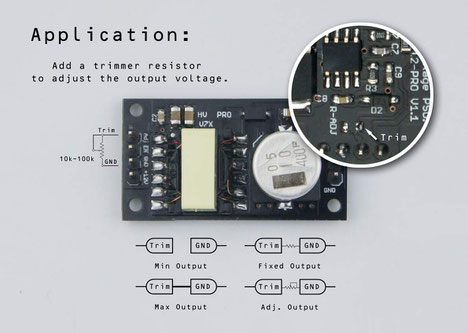

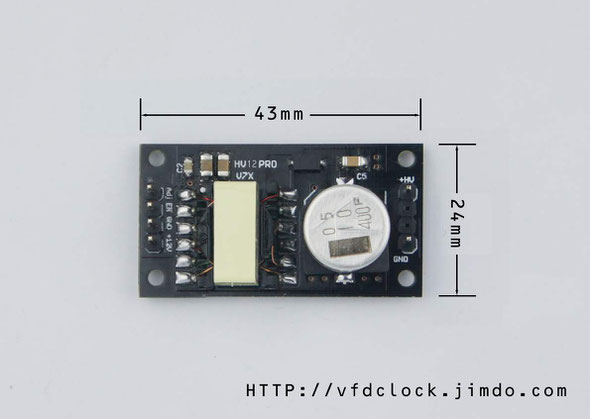

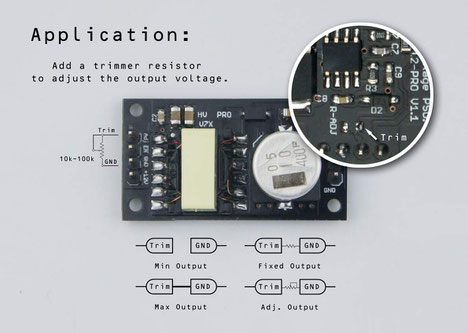

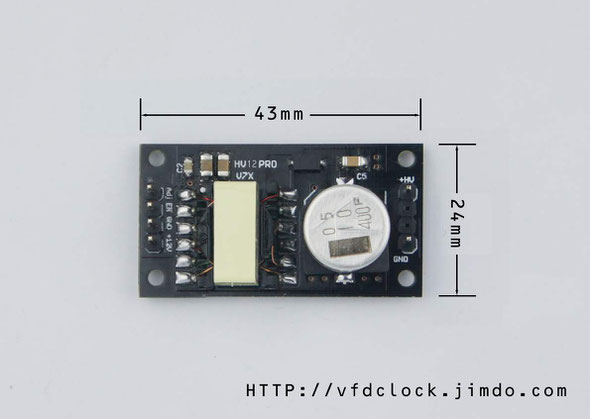

New-[HV12-Pro]-12W-Small Size-12V to 380V(Max) High Efficiency PSU for Audio Application

Sat

17

Sep

2016

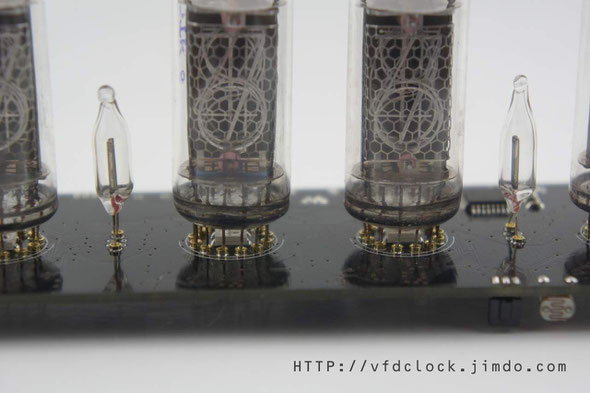

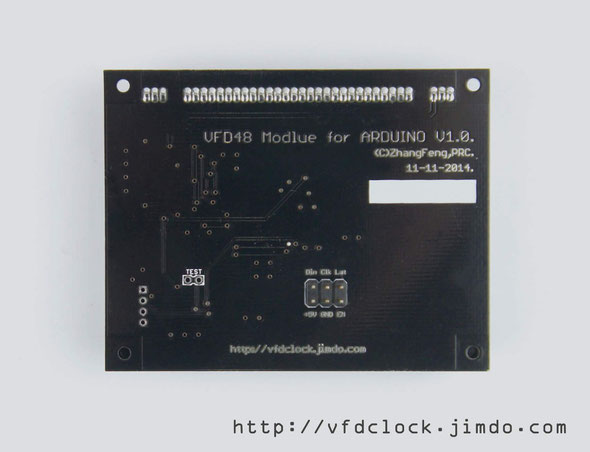

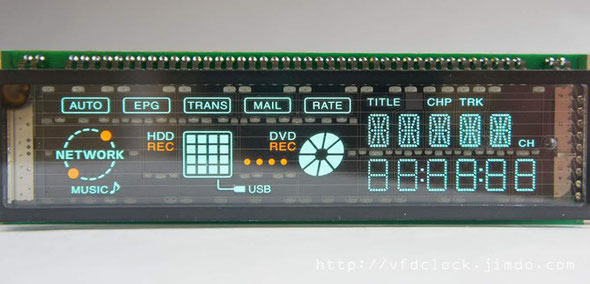

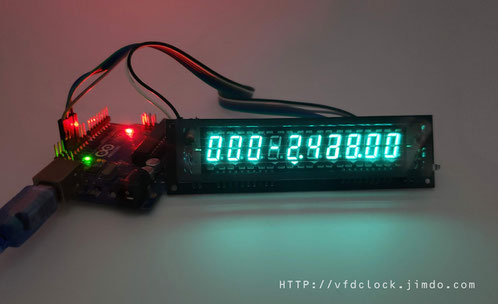

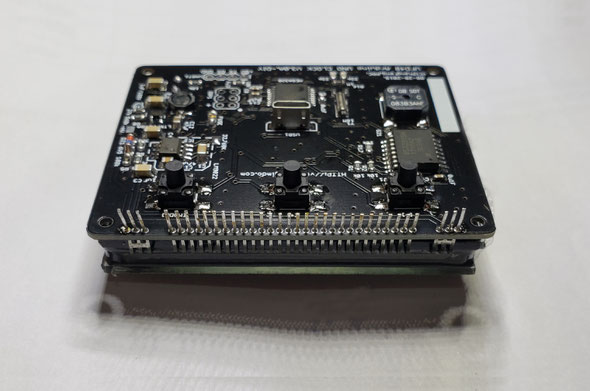

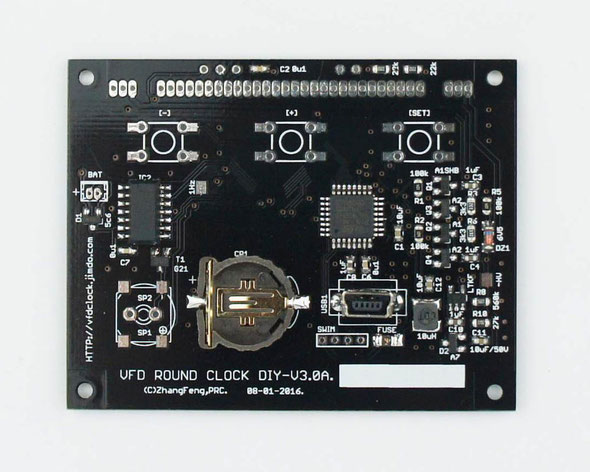

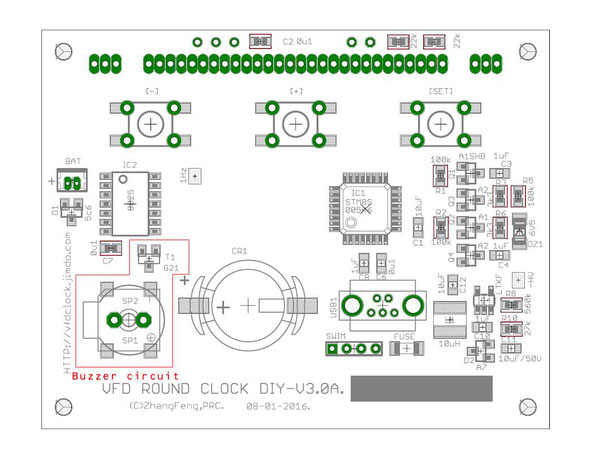

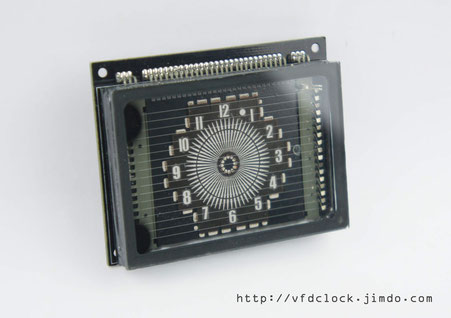

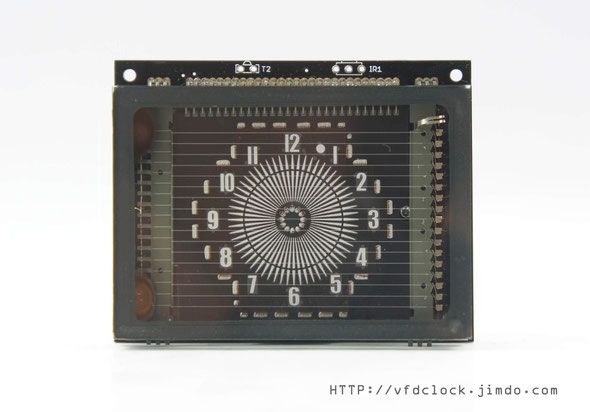

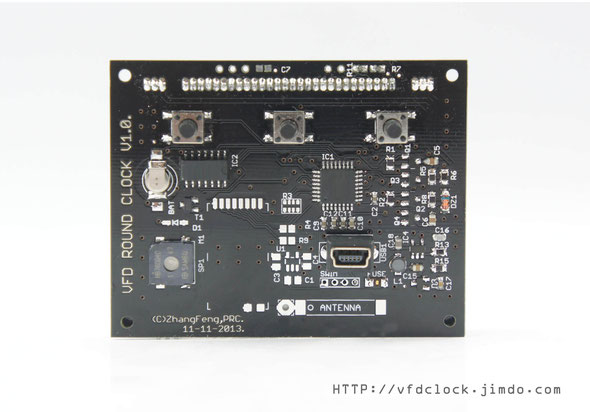

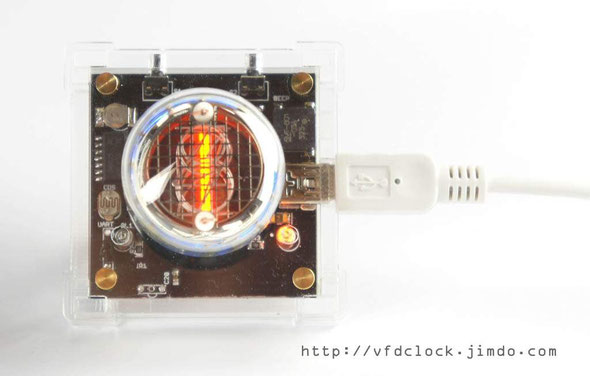

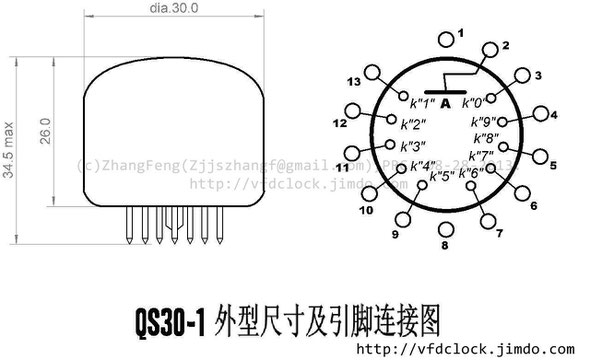

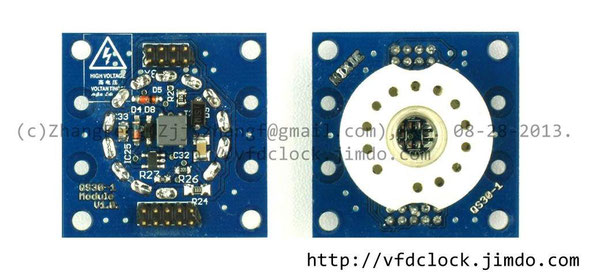

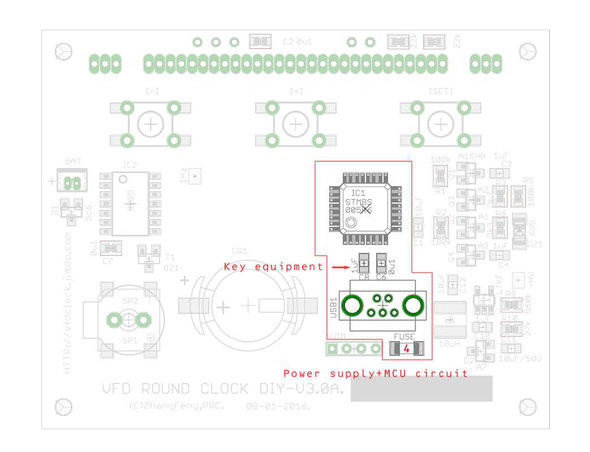

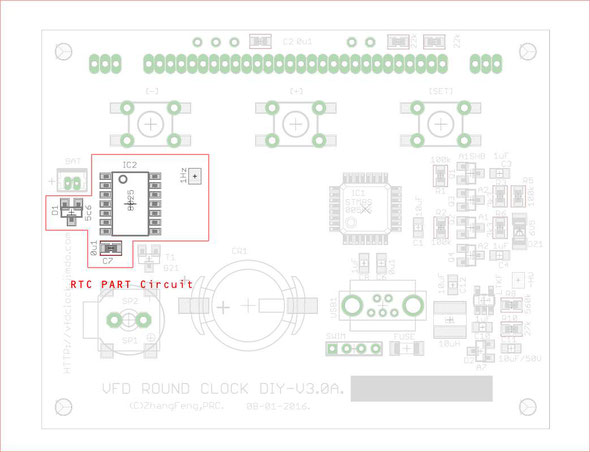

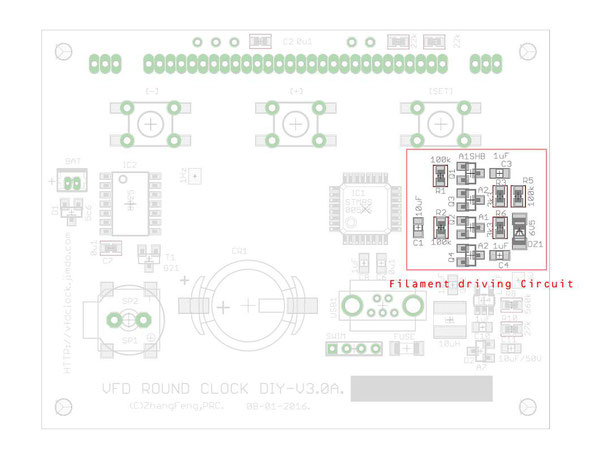

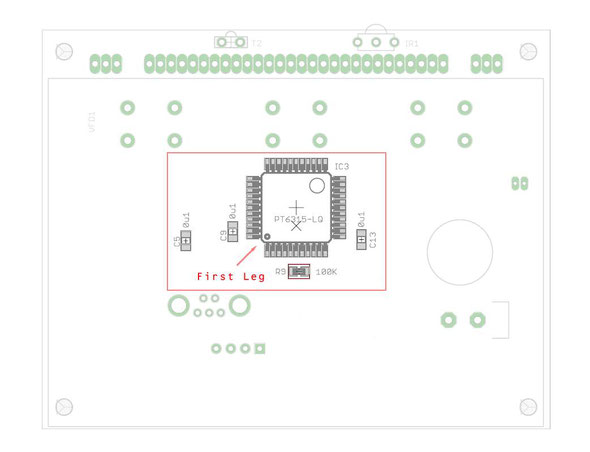

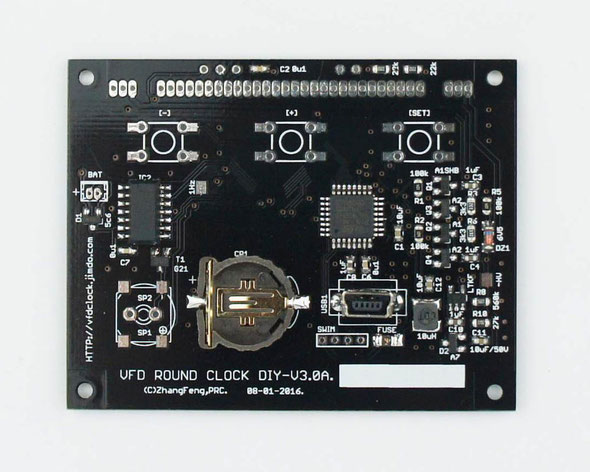

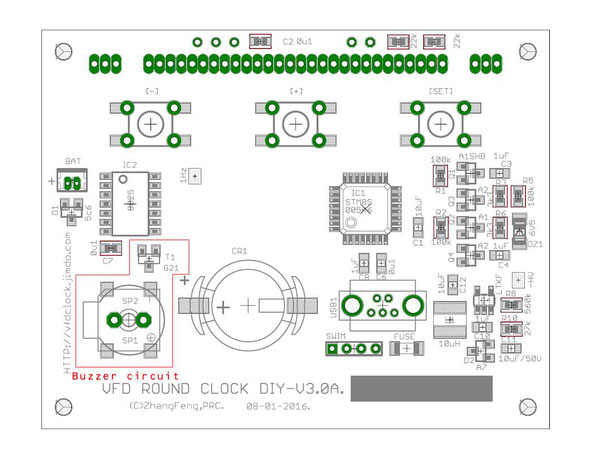

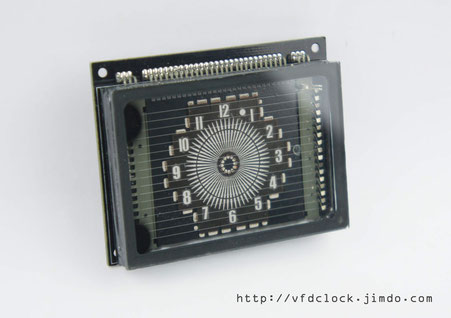

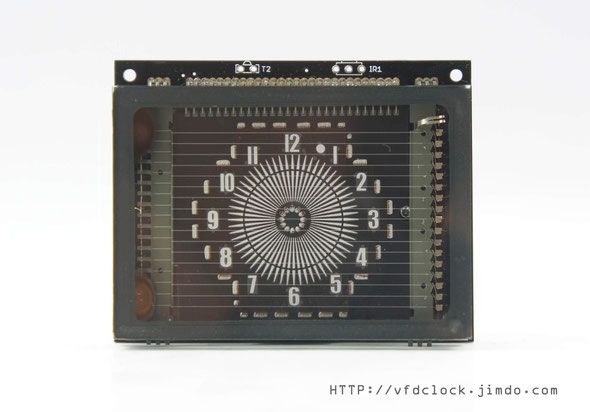

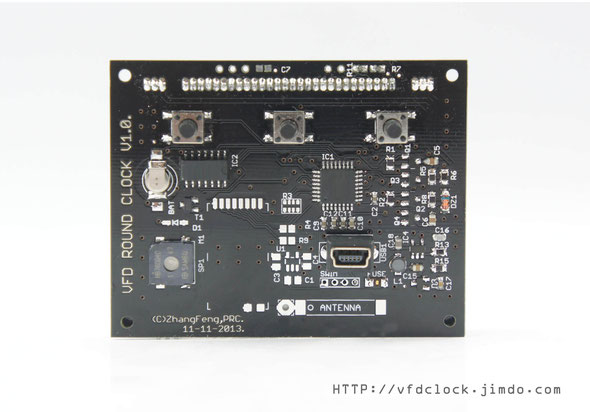

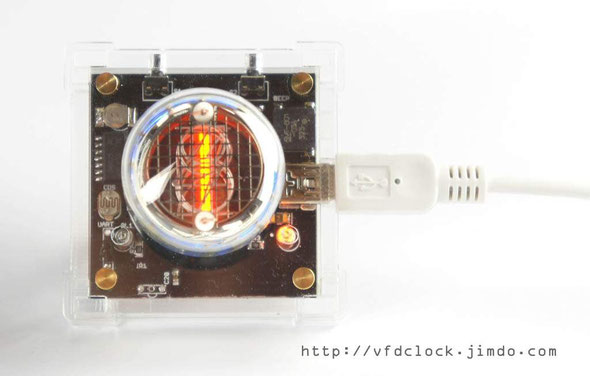

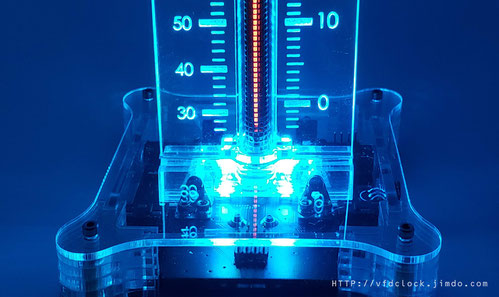

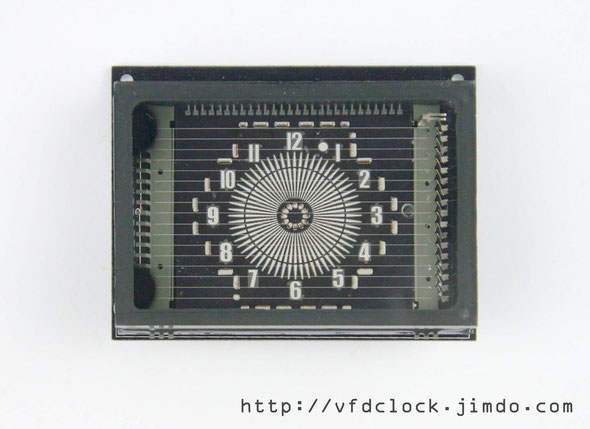

USB Powered VFD48 Analog-style Unique Round VFD Clock Assembly Instructions

Wed

31

Aug

2016

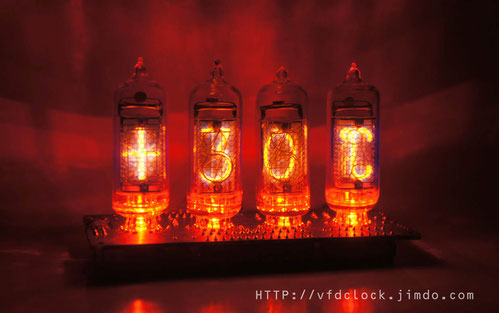

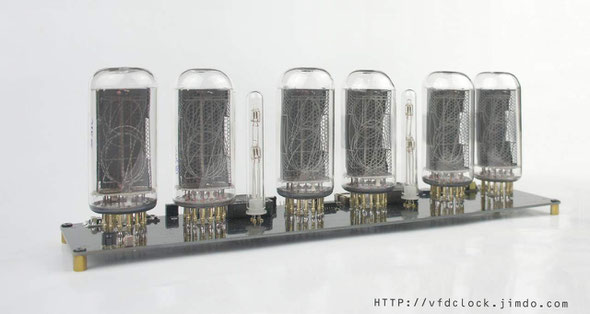

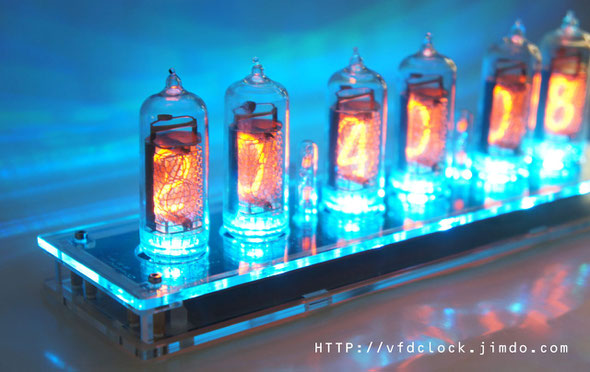

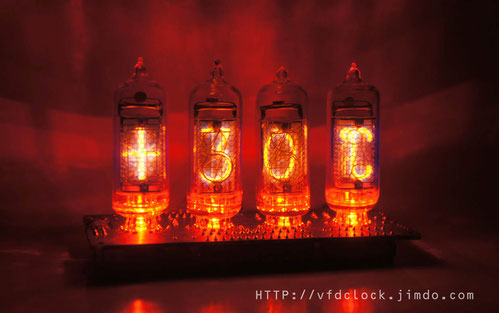

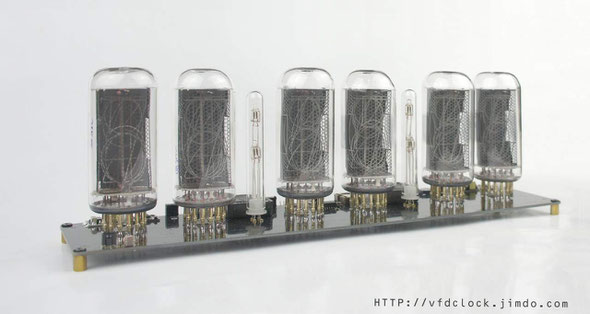

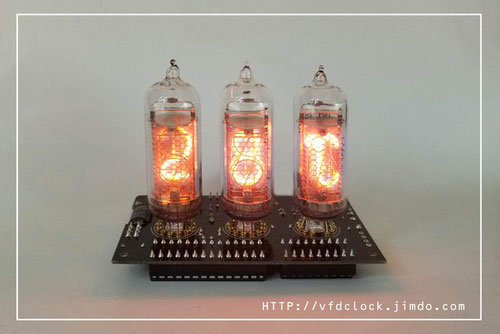

New-USB powered-IN-18 6-tube NIXIE clock with glass tube middle dots

Read More 6 CommentsSat

20

Aug

2016

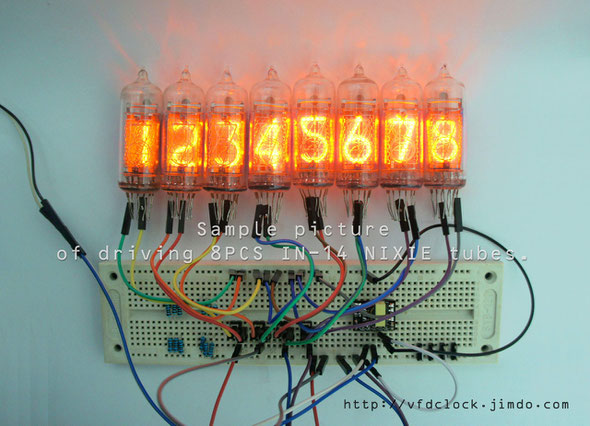

New-Plug-able IN-14 6-tube NIXIE clock with glass tube middle dots and with AC driving circuit

Read More 1 CommentsTue

26

Jul

2016

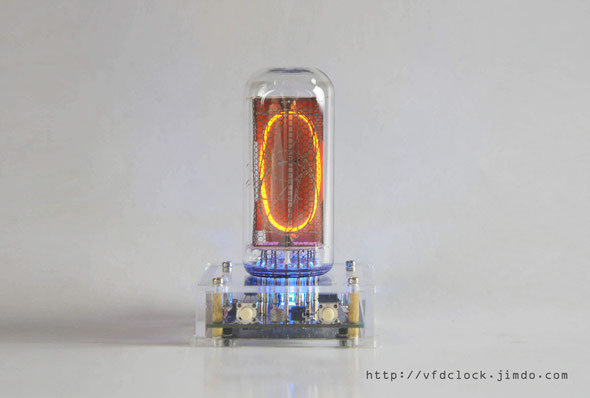

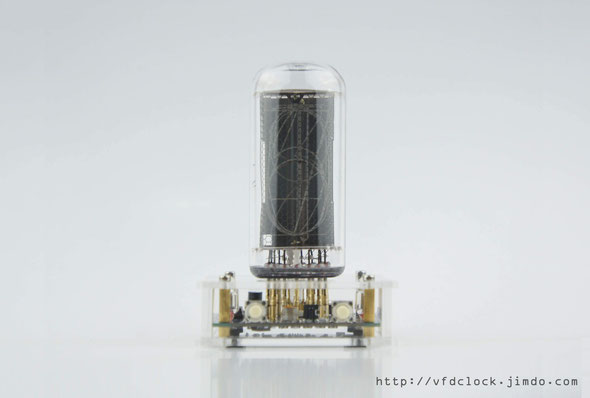

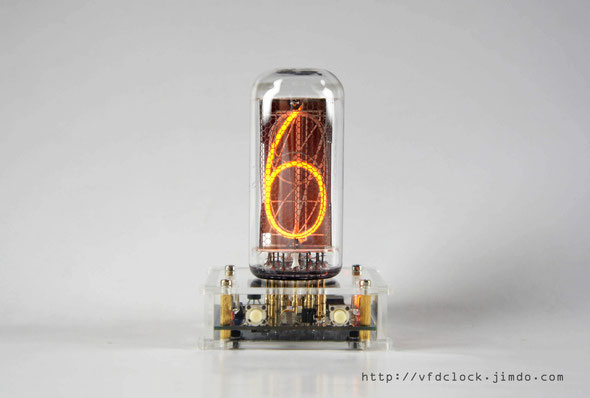

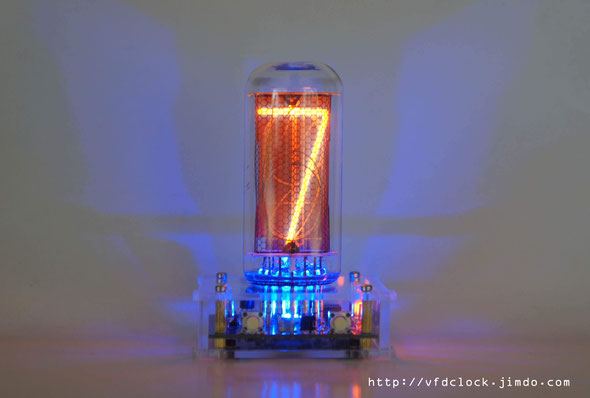

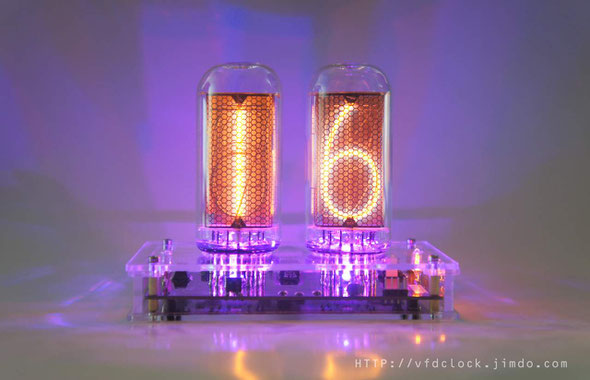

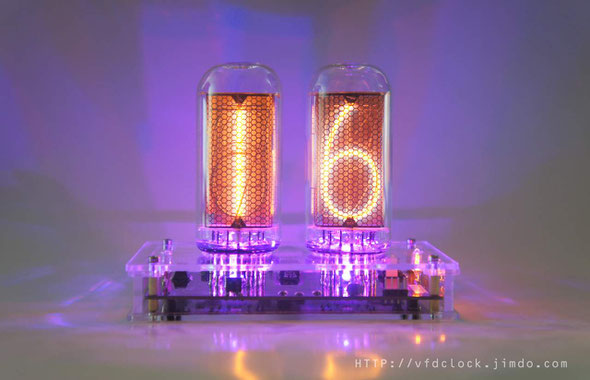

Plug-able USB Powered-Li-poly battery drive-able ,Two-Digit IN-18 NIXIE Tube Clock-Pro.

Sun

24

Apr

2016

Plug-able USB Powered-Li-poly battery drive-able ,Two-Digit IN-14 NIXIE Tube Clock-Pro.

Read More 7 CommentsMon

02

Nov

2015

Z586M Huge Single Digit NIXIE Tube Clock-Pluggable-USB Powered

Fri

23

Oct

2015

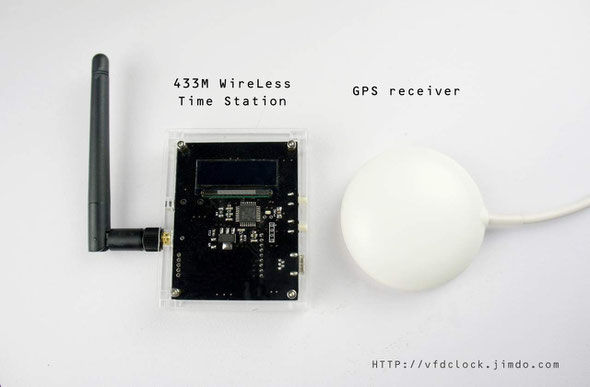

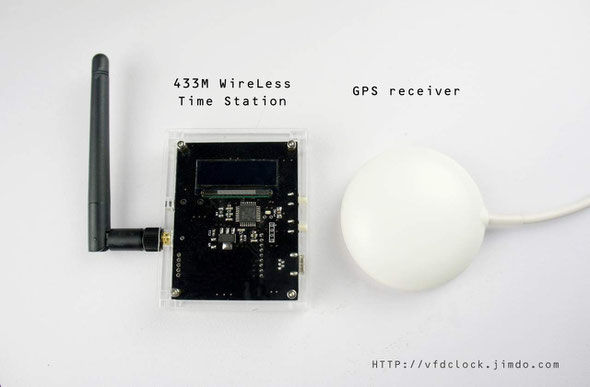

433M Wireless GPS Time Station for NIXIE clocks (OLED Version)-V1.0

Read More 2 CommentsSun

26

Jul

2015

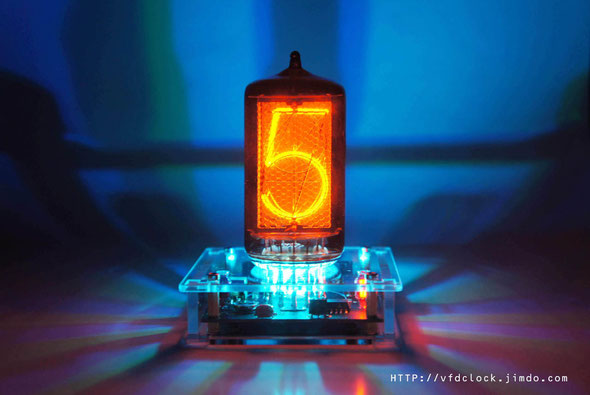

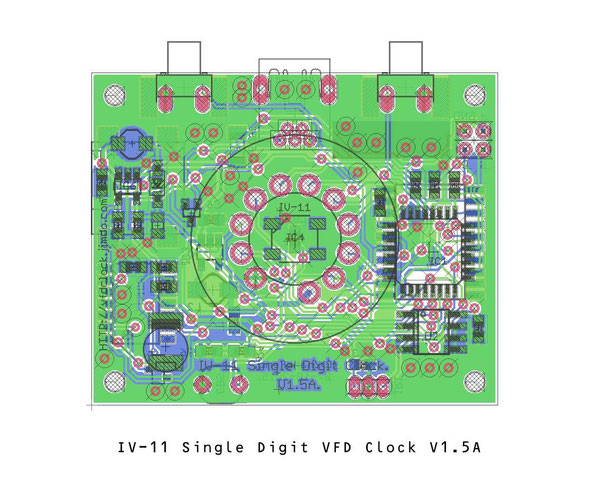

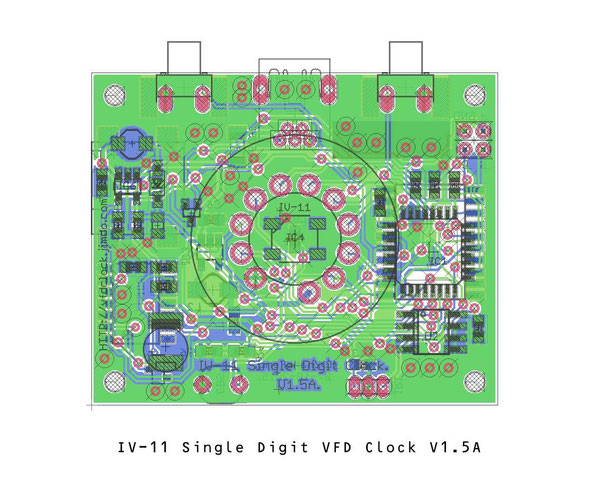

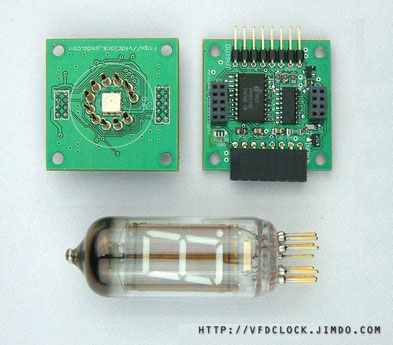

OpenHardware-Pluggable-USB Powered IV-11 Single Digit VFD Tube Clock

Sat

18

Jul

2015

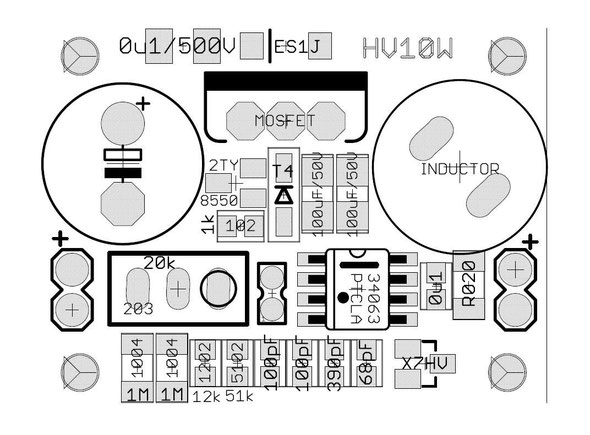

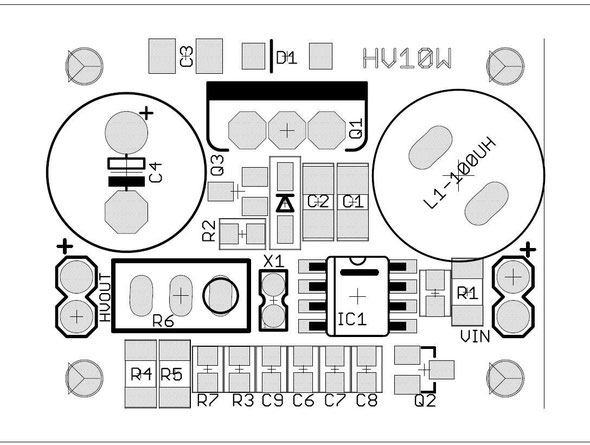

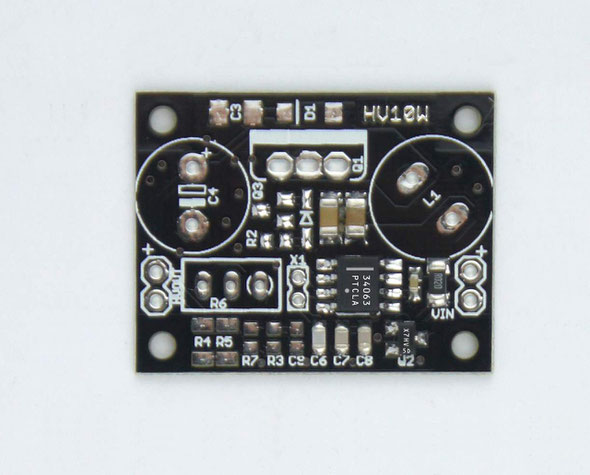

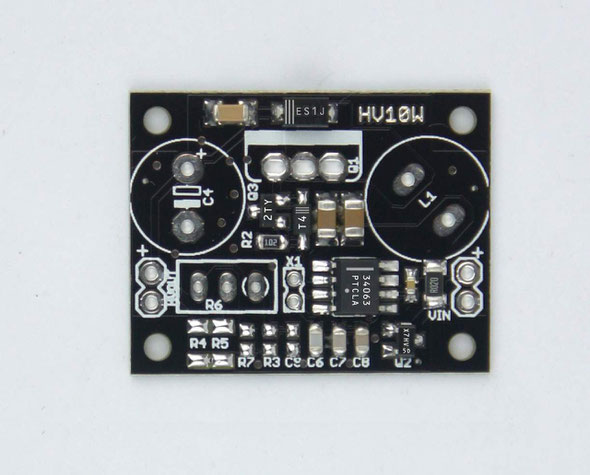

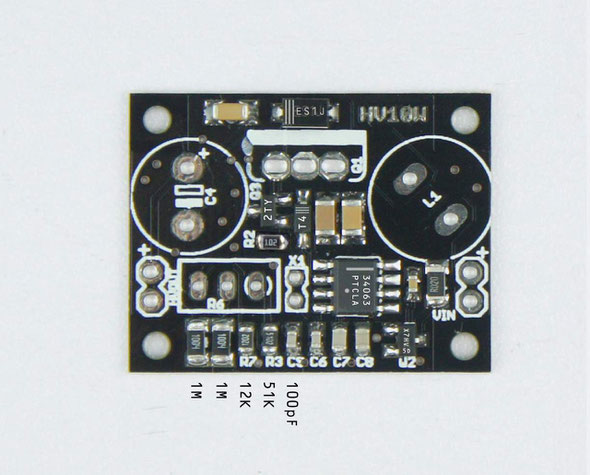

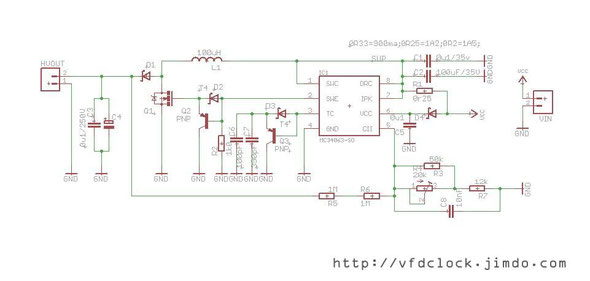

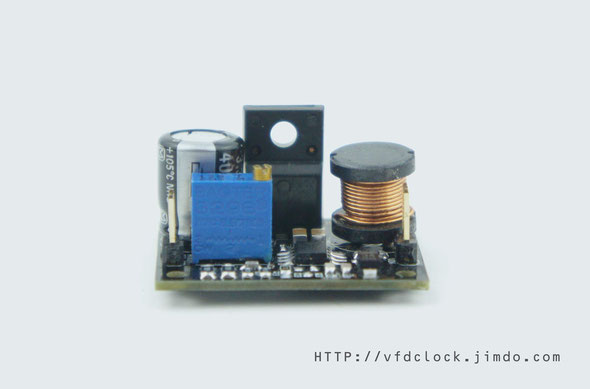

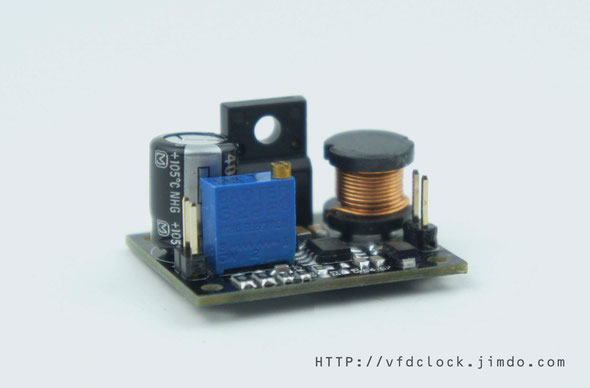

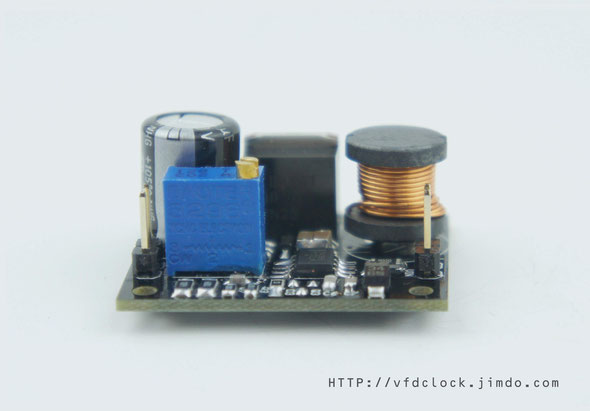

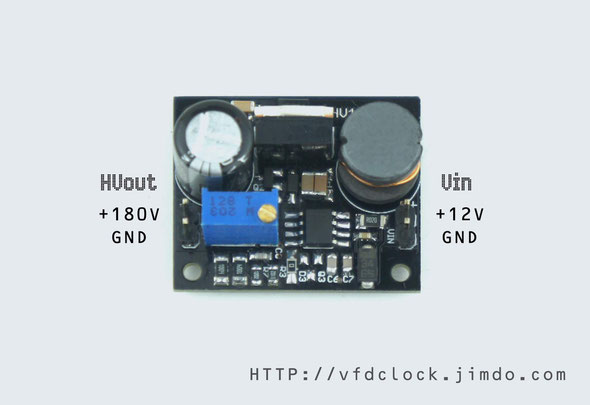

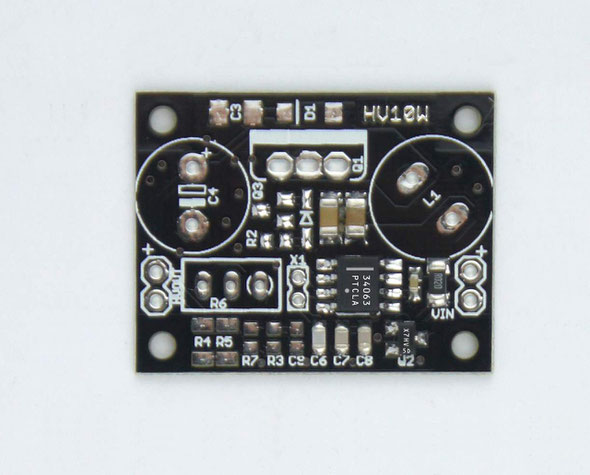

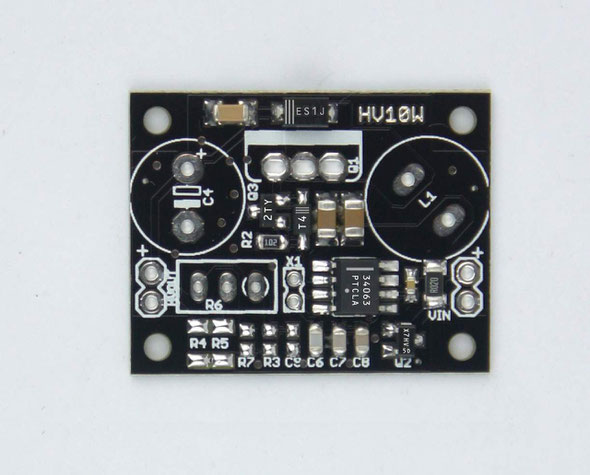

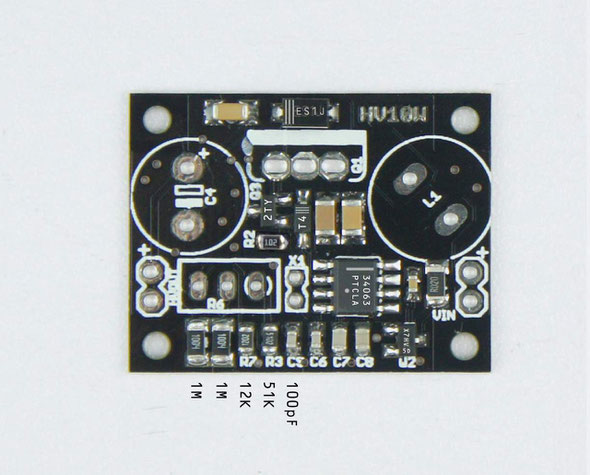

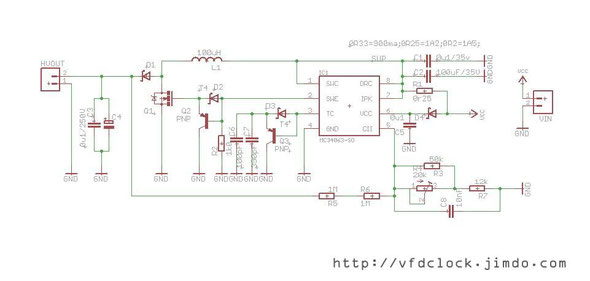

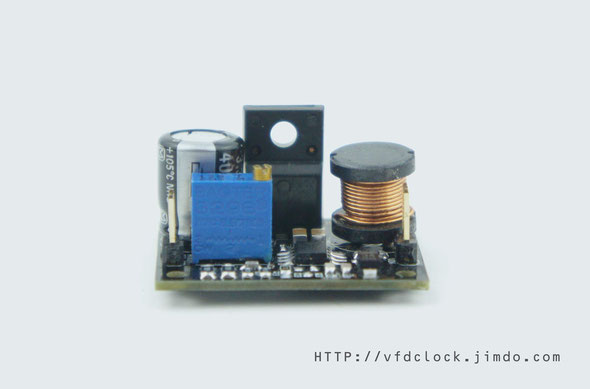

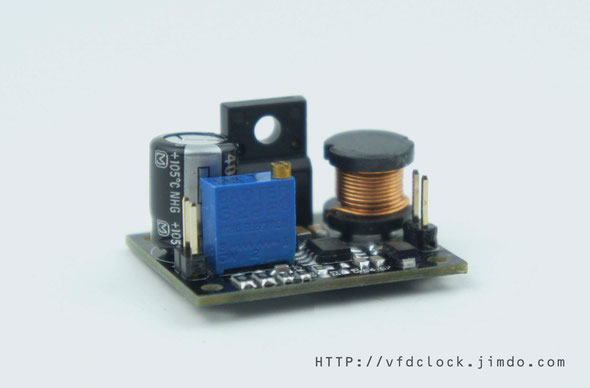

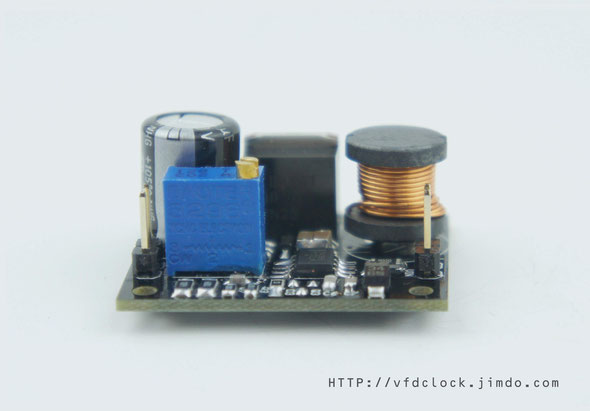

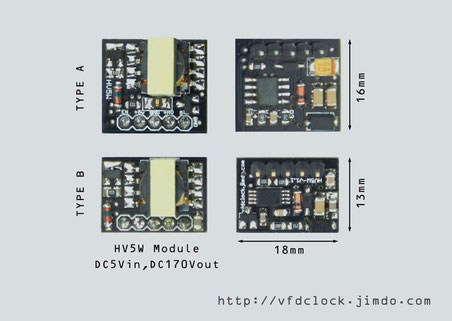

Open Hardware-Highly Optimized-10W-MC34063 based High Voltage power supply module-High efficiency up to 85%-Small Size

Wed

01

Jul

2015

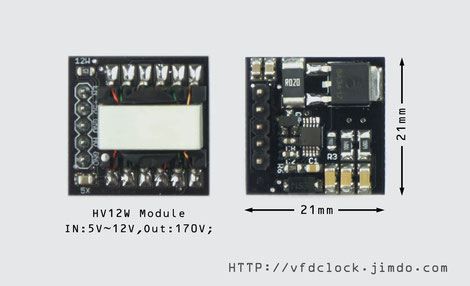

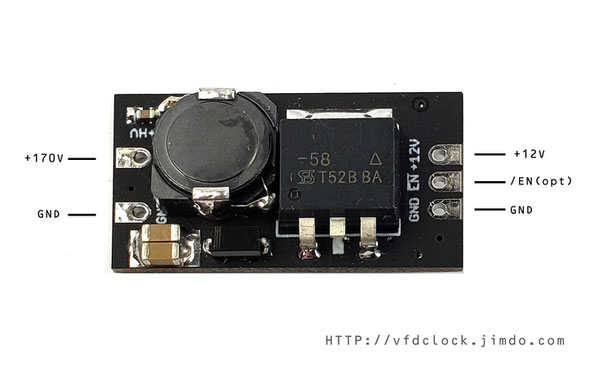

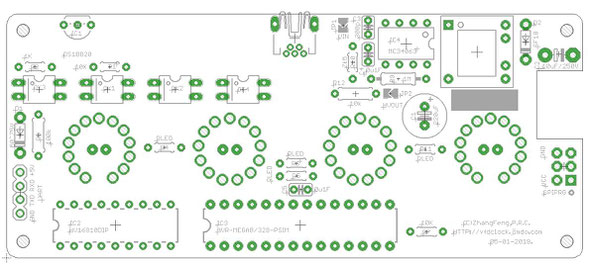

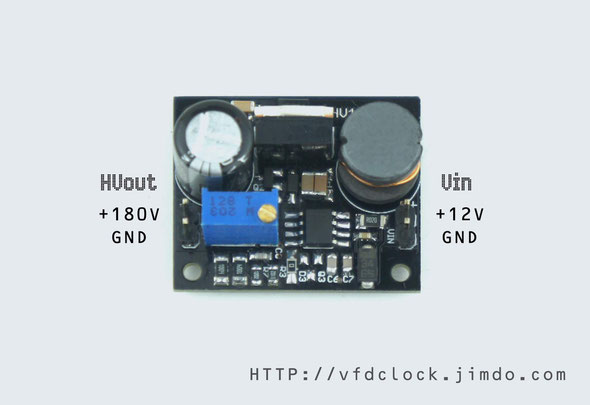

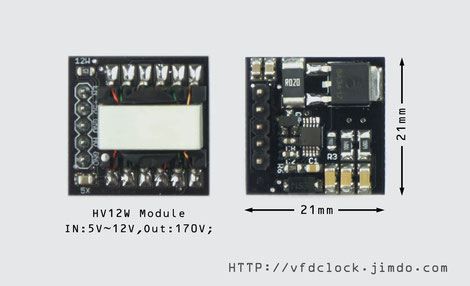

New-HV12W PSU,5V~12V DC in,170V DC out,designed for driving 6-tube IN-18 NIXIE clock-92.6%(Max) high efficiency

Thu

04

Jun

2015

10W-120kHz High Voltage Supply Module-Designed for Audio Amplify Circuit

Mon

25

May

2015

Open Hardware-MC34063 based High Voltage Power Supply Module-10W

Fri

08

May

2015

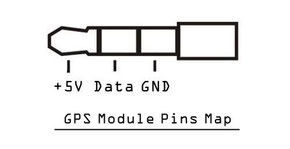

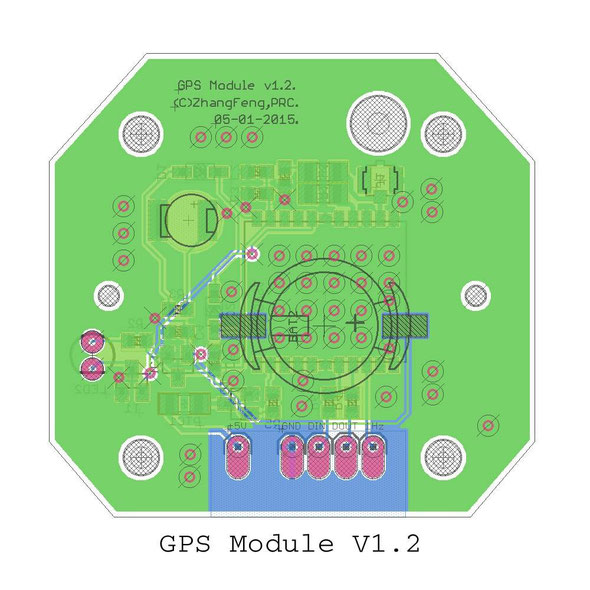

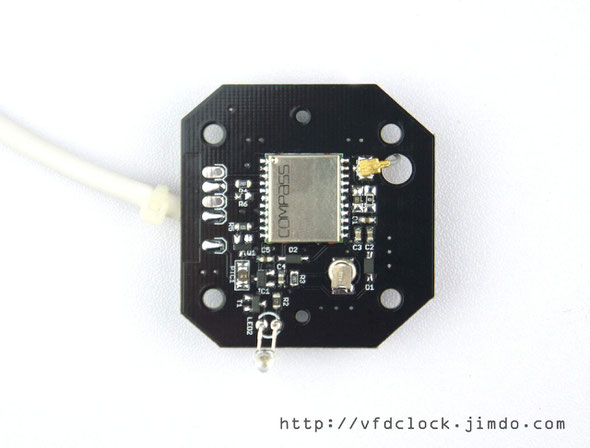

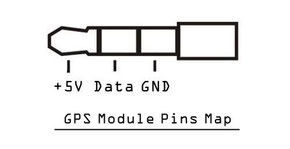

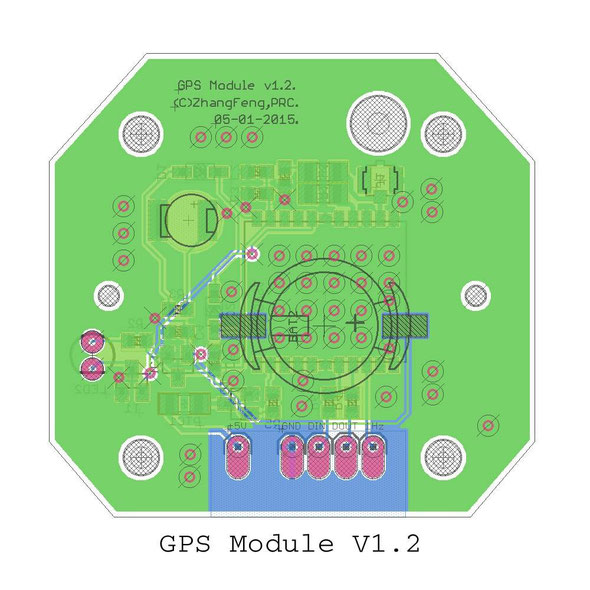

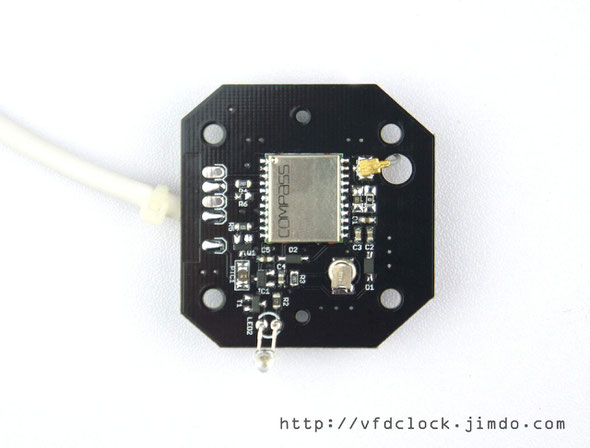

Open Hardware - GPS Receiver Module for NIXIE/VFD clocks

Thu

15

Jan

2015

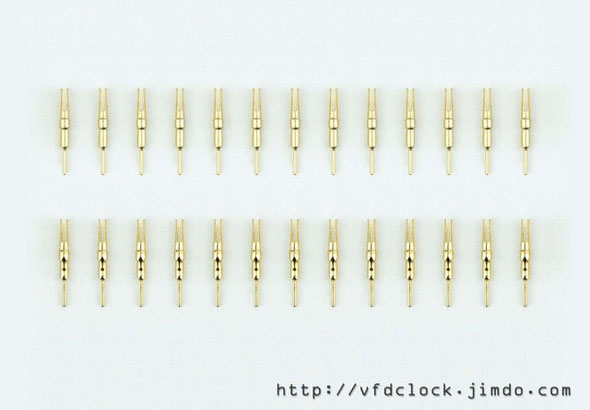

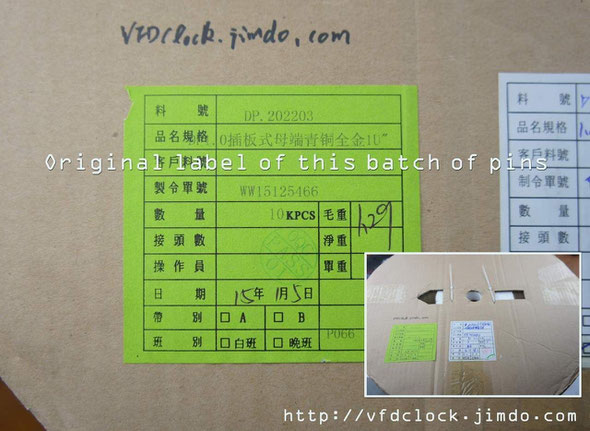

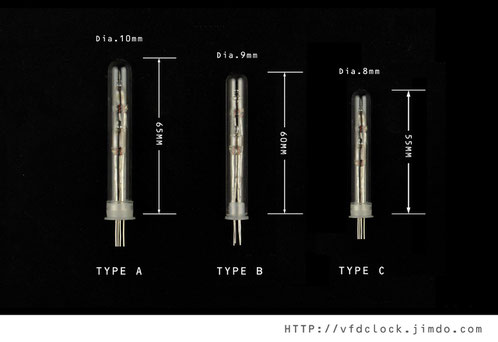

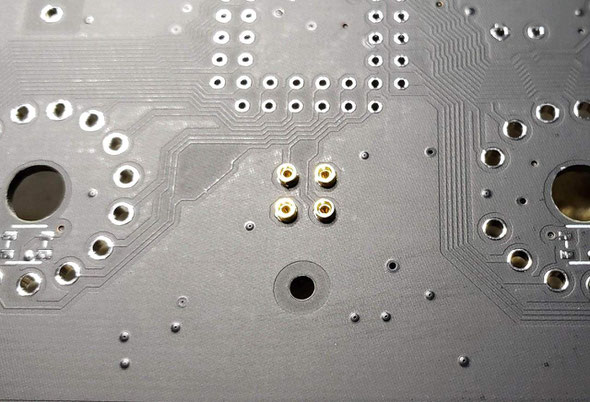

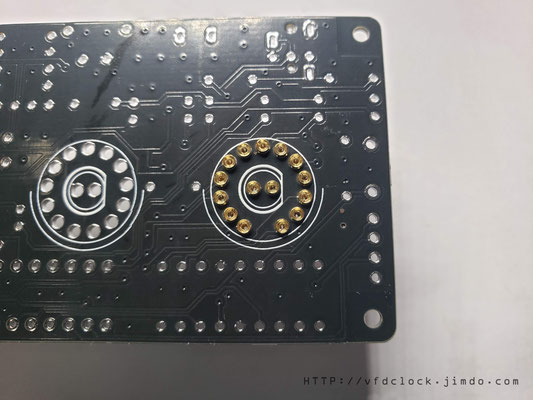

Customized the NIXIE PINS from the factory,1U gold plated,Very high quality

Read More 1 CommentsSun

17

Aug

2014

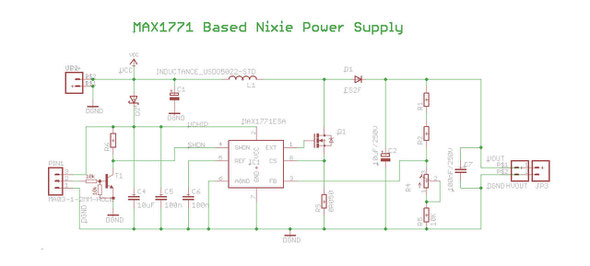

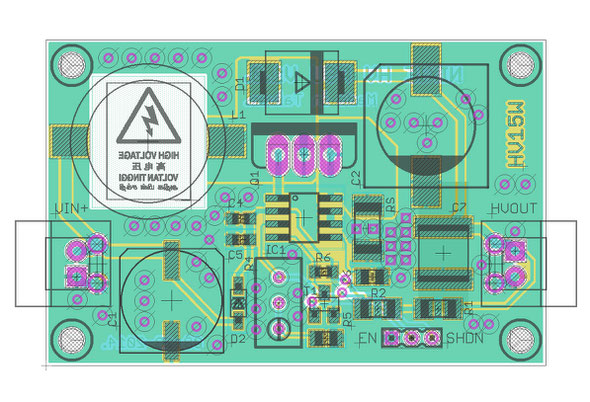

New-HV15W High Voltage NIXIE and Magic Eye Tubes PSU,Power Supply Module V1.0 Std.-MAX1771 Version

Tue

22

Jul

2014

BOE VFD48圆盘时钟正式版-USB Powered BOE VFD48 Analog-style Unique Round VFD Clock With Enclosure

Read MoreSat

19

Jul

2014

USB供电的单管6E2猫眼音量指示器-USB Powered 6E2(EM84) Magic Eye VU Meter(Audio Visualizer)-V1.0

Read MoreSat

19

Jul

2014

IN-8 and IN-8-2 Single Digit NIXIE Clock V1.0

Wed

02

Apr

2014

IV-11 单管VFD时钟 IV-11 Single Digit VFD CLock V1.0

Wed

02

Apr

2014

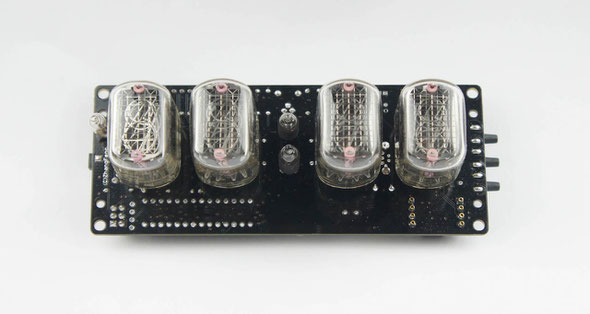

IN-12A/B 单管辉光时钟,IN-12A/B Single Digit NIXIE Clock V1.0

Wed

08

May

2024

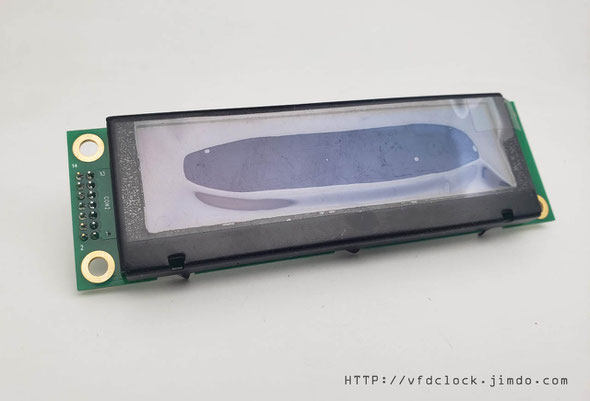

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

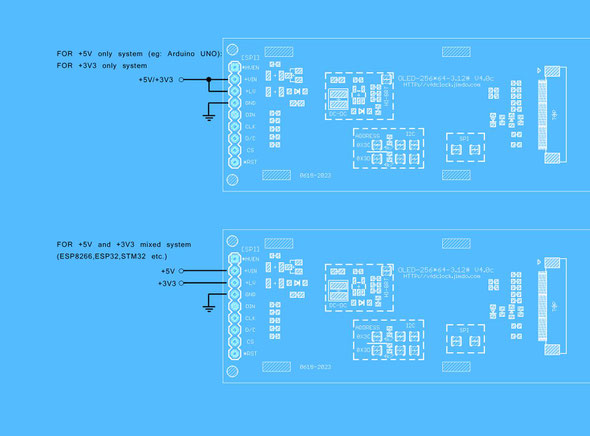

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Wed

08

May

2024

HGS256642 3.12# YELLOW OLED display module

Features:(For reference only)

HGS256642 3.12# YELLOW OLED display module

Main Power:+3V3 only(Do not use 5V!!!)

Logic level:+2V8~+3V3

Current:~280mA

Driver IC:SSD1322

Module Size:105.6mm(L)x31.8mm(W)x9.5mm(H) (MAX.)

Visible Area: 78.78mm(L)x21.18mm(W)

Res:256*64

Color:Yellow

MCU Interface:

(Interface can be changed by soldering the 0R resistor on the back of PCB):

8-bit 8080(In default)

8-bit 6800

4Wire SPI

3Wire SPI

CON:14pin(2mm gap)

ARDUINO U8G2 lib can driver it directly,have tested om ESP8266 and ESP32-C3 platform via SPI 4-wire mode;

In editing..................

Mon

08

Apr

2024

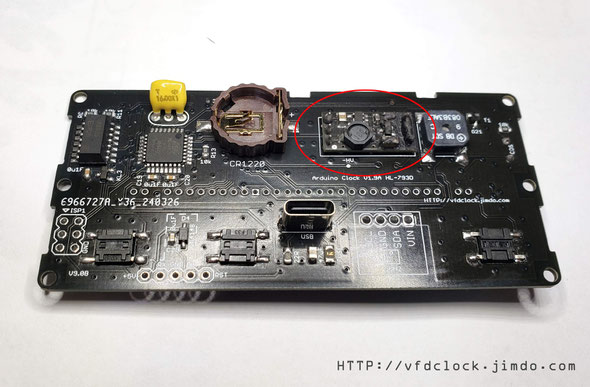

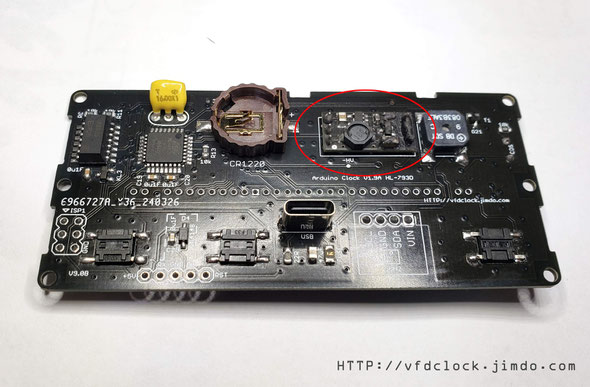

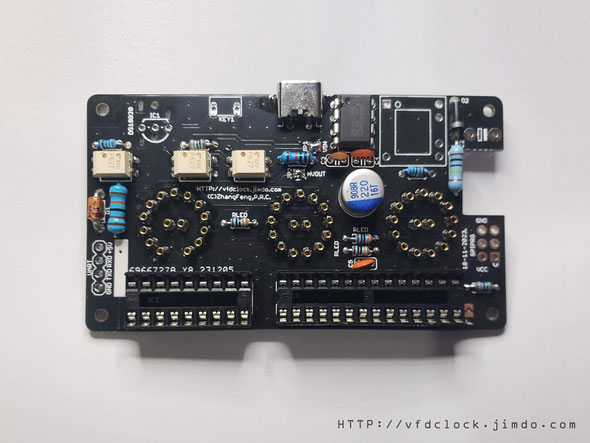

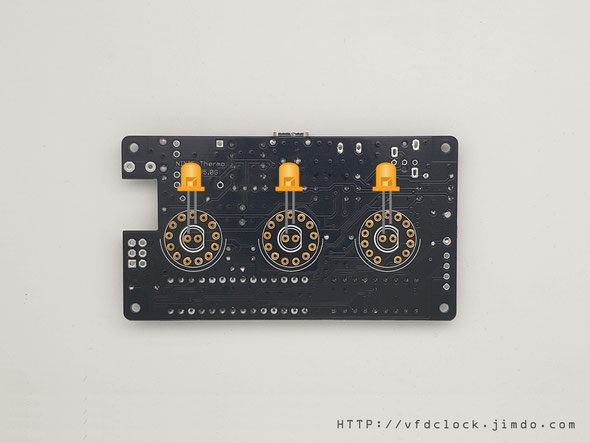

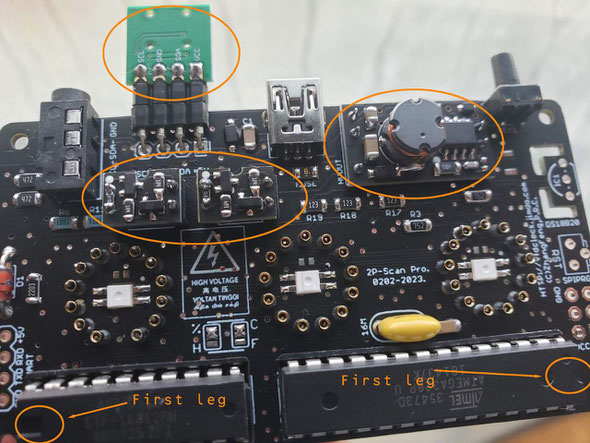

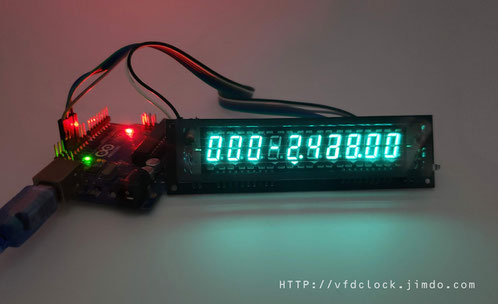

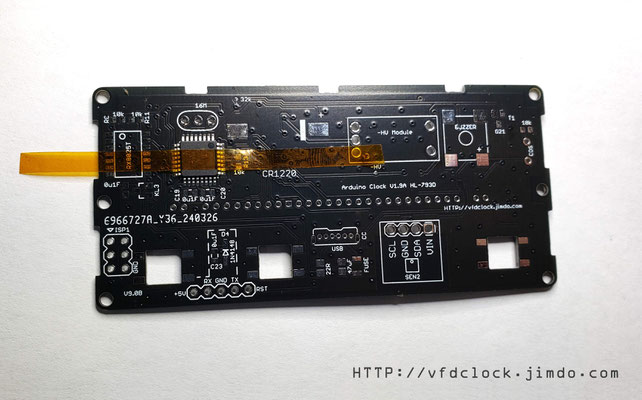

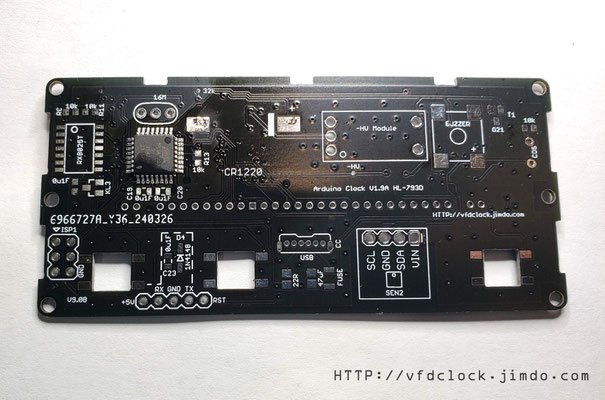

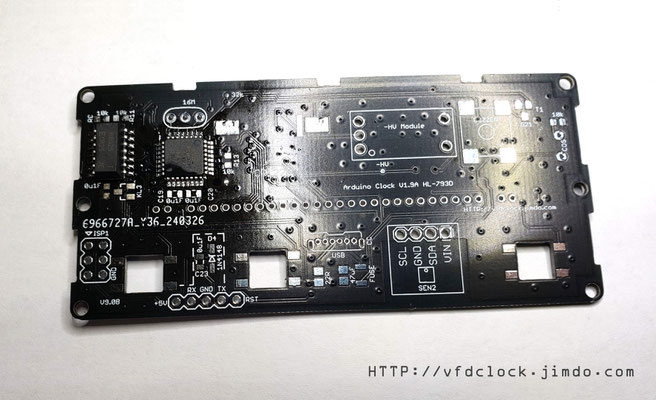

5V USB powered Open Source Arduino VFD clock Assembly Instructions

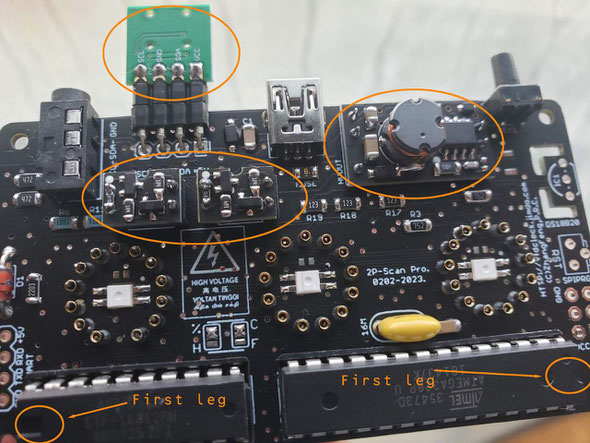

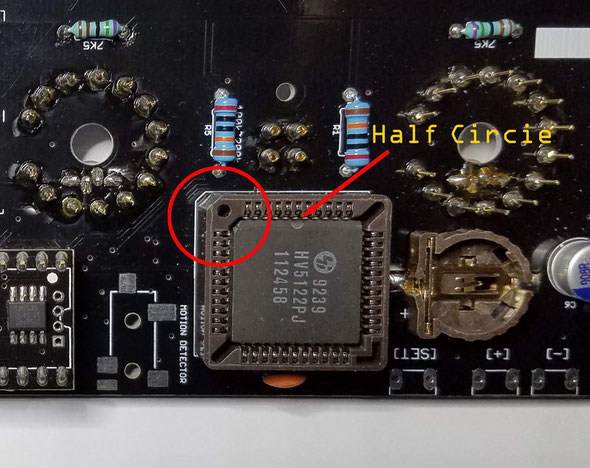

1. It is recommended to start the welding work from the front first. The first part to be welded is the PT6513 driver IC. Use tape to temporarily fix the IC on the PCB and align the pins of the

IC. Please pay special attention to the direction of the first pin and do not mess with it. wrong;

Then apply flux on the pins and use a soldering iron to solder; use a magnifying glass to inspect after the soldering is completed to ensure that the pins are soldered correctly and there are no

false soldering or short circuits;

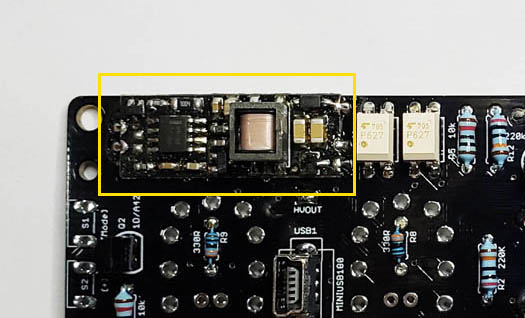

2. Solder the LM9022/AP9022 integrated circuit using the same method, also paying attention to the direction of the IC;

3. When welding the resistors, capacitors, diodes and other parts on the front, please pay attention to the correct placement direction of the diodes;

4. Turn the PCB over to the reverse side and use the same technique to solder the MCU Mega328 and RTC RX8025T, as well as other RCL and other parts; C23 and D4 on the lower left side are optional parts and are only used for the online UART programming port. If not needed Modify the program without welding;

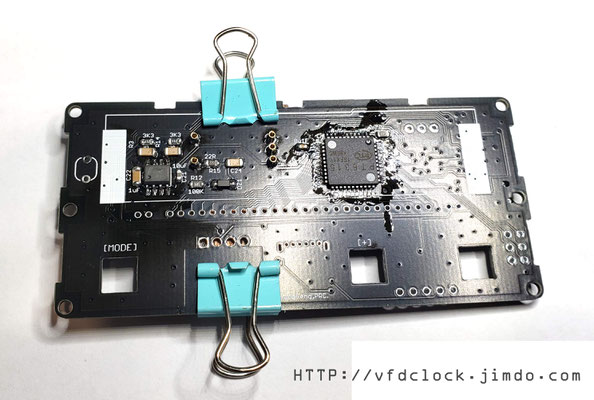

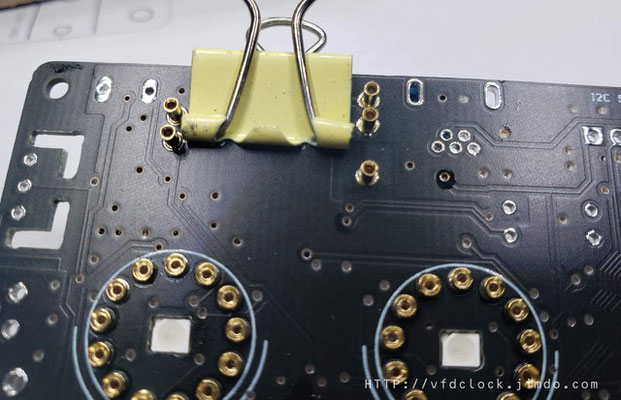

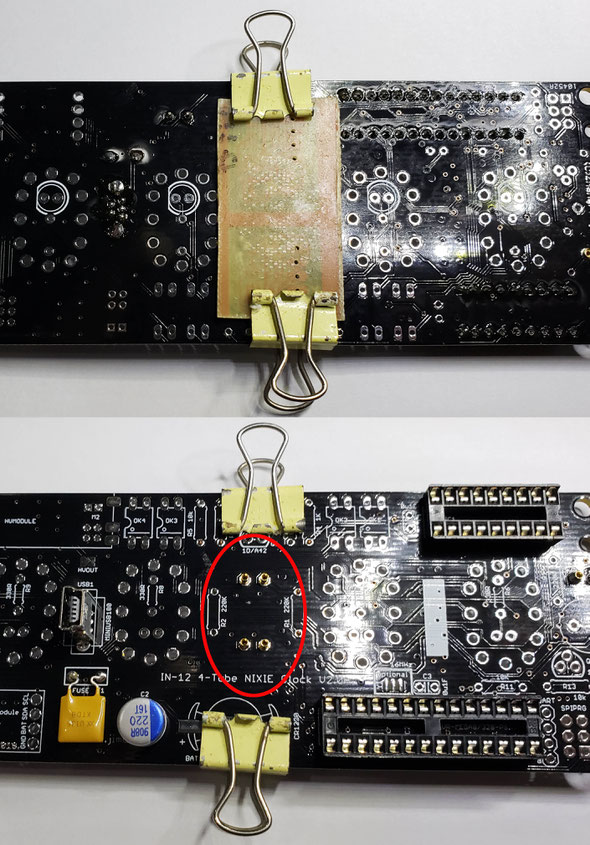

5. Then solder the female pin part used by the HV power module. First insert the female pin into the PCB, then cover it with a hard board, you can use PCB or wood chips, use clips on both sides to clamp the PCB, then flip the PCB over and solder the lower part;

6. Weld the 16M crystal (the pins have no directionality), CR1220 battery holder (please pay attention to the installation direction) and CDS photosensitive sensor (it is recommended that the installation height does not exceed the height of the VFD screen);

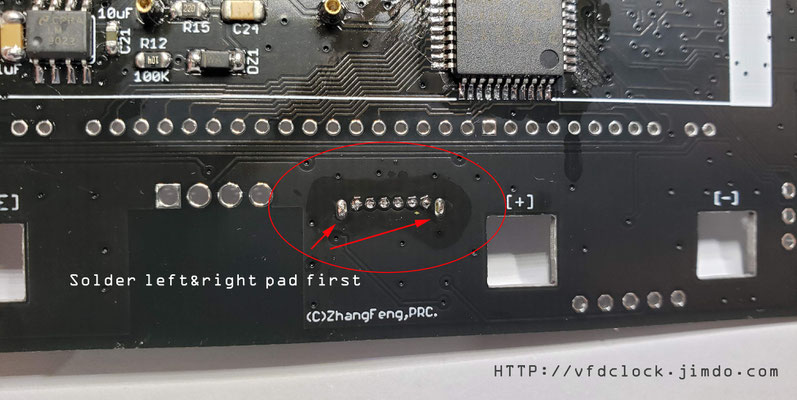

7. Solder the USB socket. First, insert the USB socket into the PCB. There is only one direction for insertion (as shown in the picture). Then flip the PCB and solder the left and right mounting pins first. After confirming that the USB position is correct and the installation is not skewed, you can solder the other ones. Pin; after the soldering is completed, flip the PCB over and add solder to the left and right lower sides of the USB socket to make it secure;

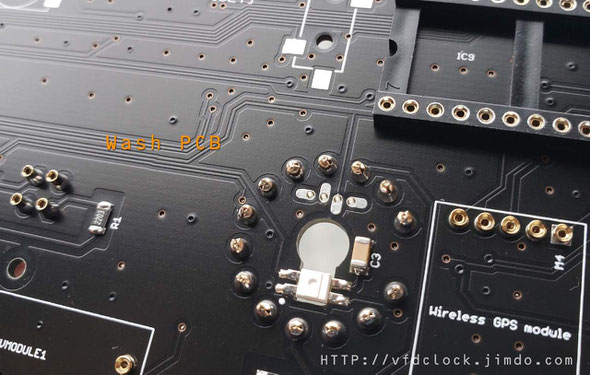

8. After the above welding work is completed, you can use alcohol and other cleaning agents to clean the PCB; because the RTC contains crystals, ultrasonic cleaning machines are not allowed!

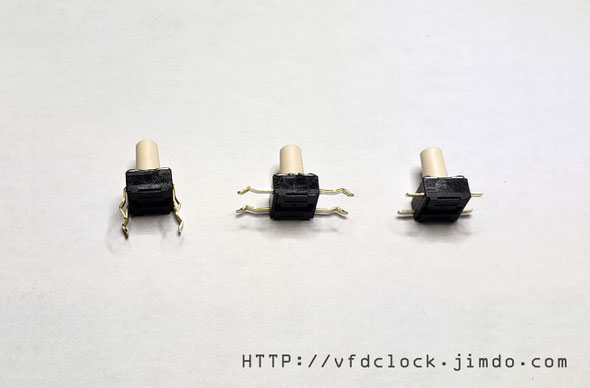

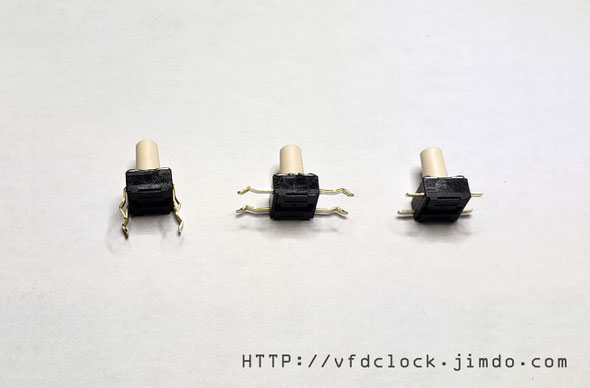

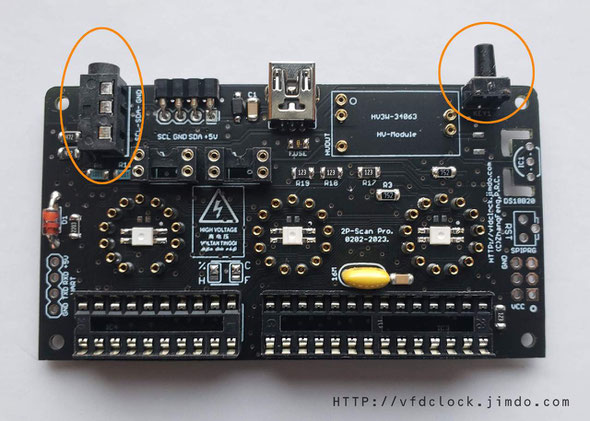

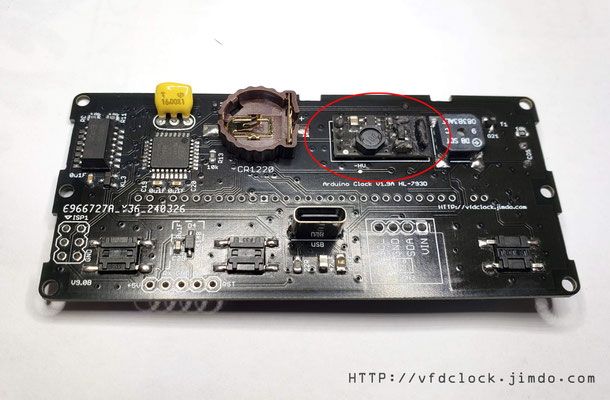

9. Then weld the buttons and other parts. First, unfold the four legs of the button, flatten them with a tool, cut them short, and then insert them into the PCB mounting holes for soldering. The buttons have two specifications, the taller one is used for the [mode] button, and the two shorter ones are used for the [+] and [-] buttons; after the button welding is completed, the speaker can be welded (please pay attention to the "+" pin direction). After completion, the -HV power module can be inserted;

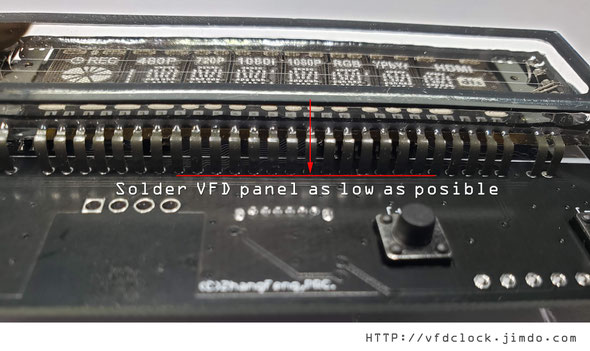

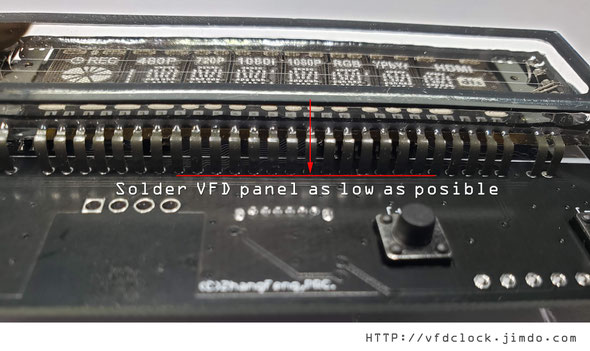

10. Install VFD screen. Before installing the screen, please confirm that the circuit board is working correctly. First insert the VFD screen into the circuit board, then apply force on one side to press the pins against the inner wall of the installation hole, and then plug it in for testing. If the VFD screen lights up correctly and displays normally , the pins can be soldered, otherwise the PCB fault needs to be eliminated before proceeding to the next step. When welding, make sure the screen pins are pressed as low as possible and as close to the PCB as possible (as shown in the picture), otherwise it may not be installed into the housing later;

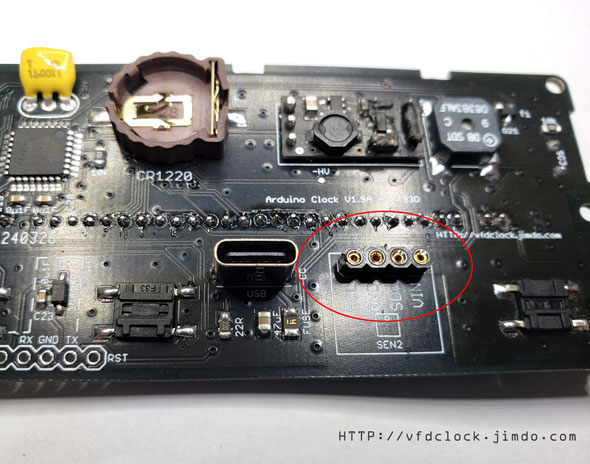

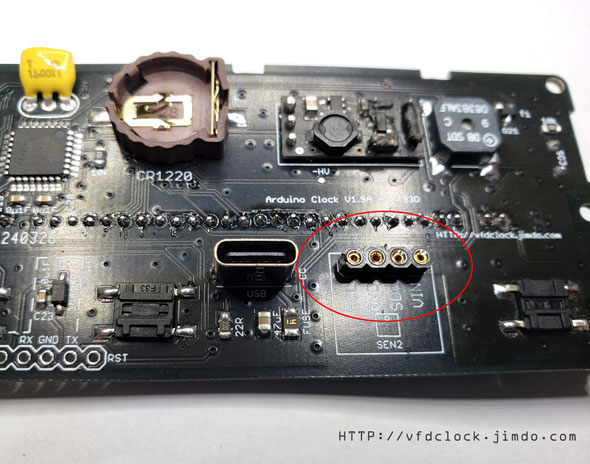

12. Additional functions: If the clock is equipped with a temperature and humidity display function, you need to weld an installation socket for the temperature and humidity sensor, and directly weld the 5pin female socket to the corresponding position.

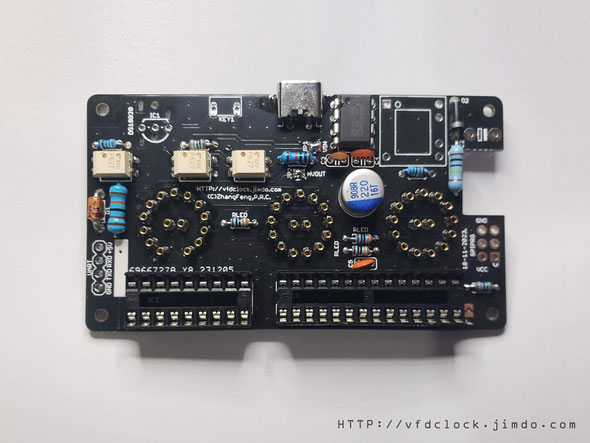

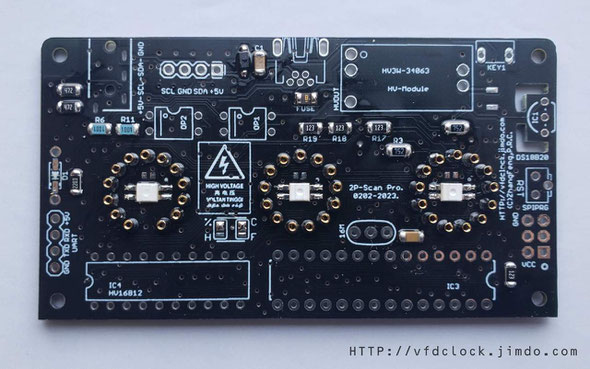

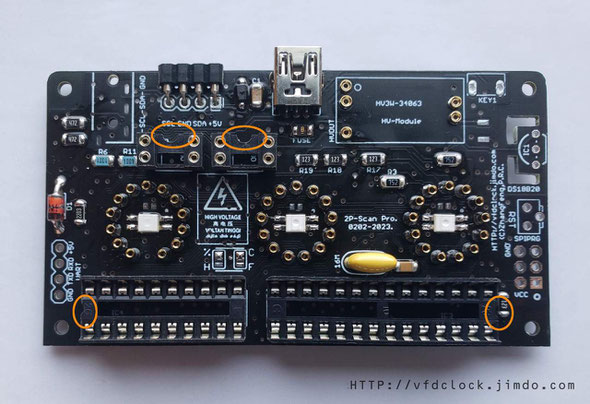

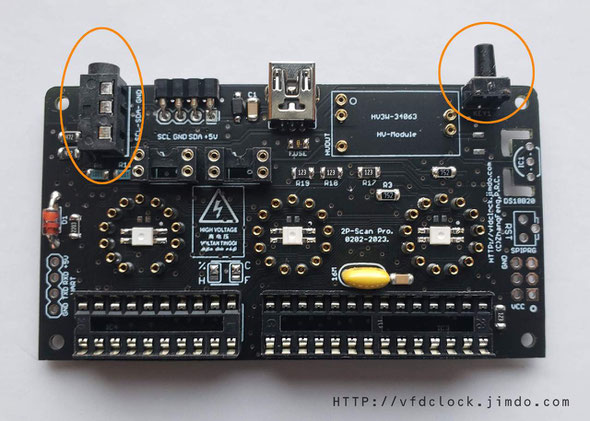

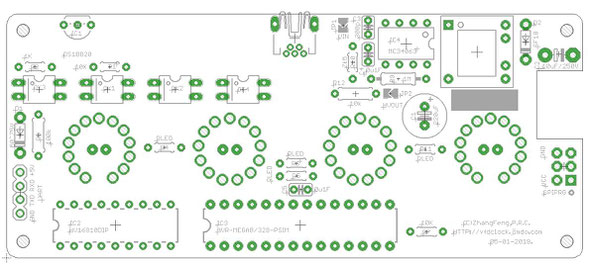

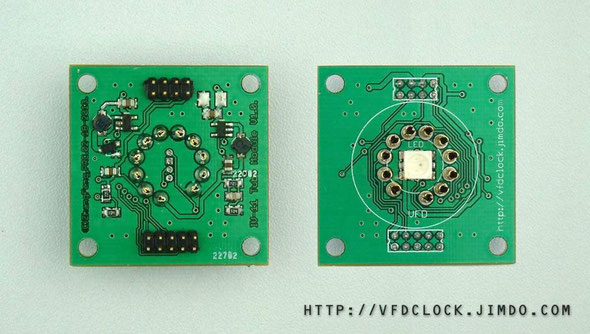

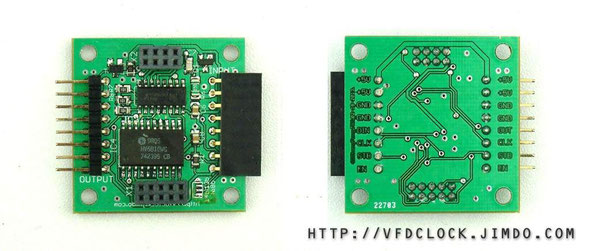

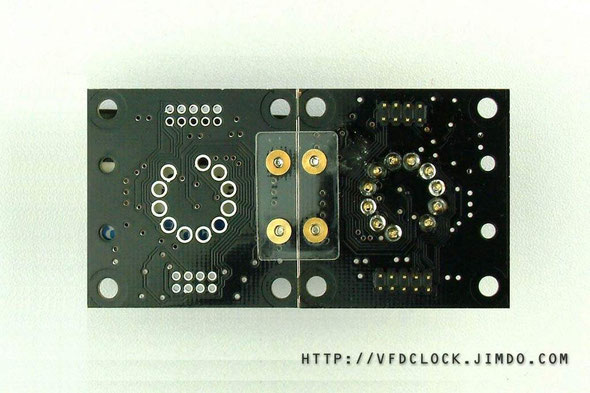

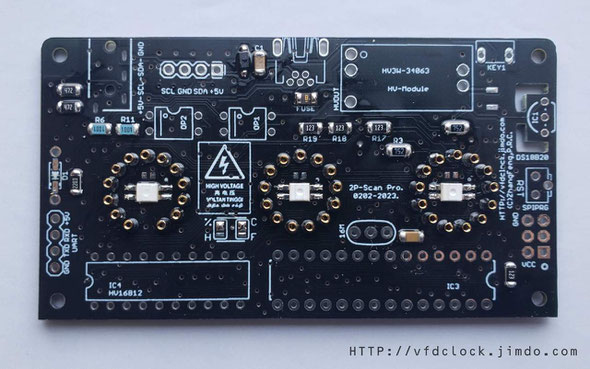

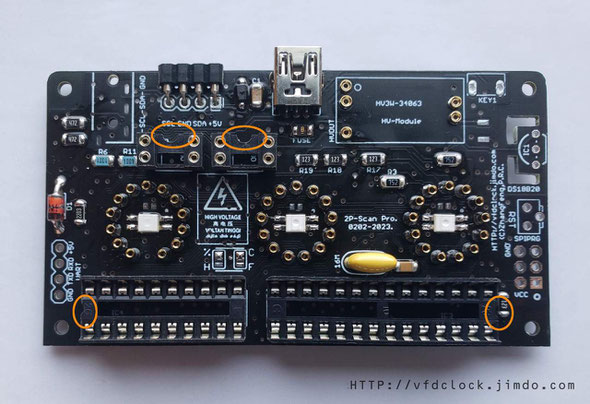

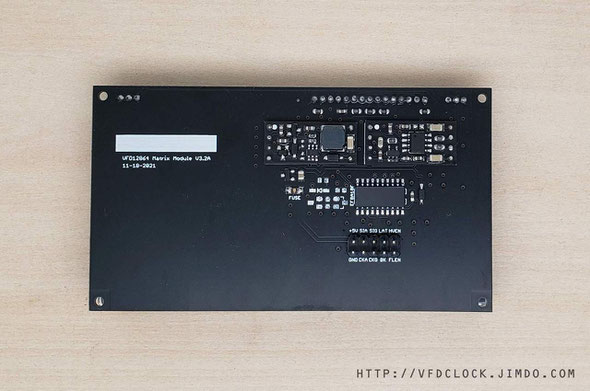

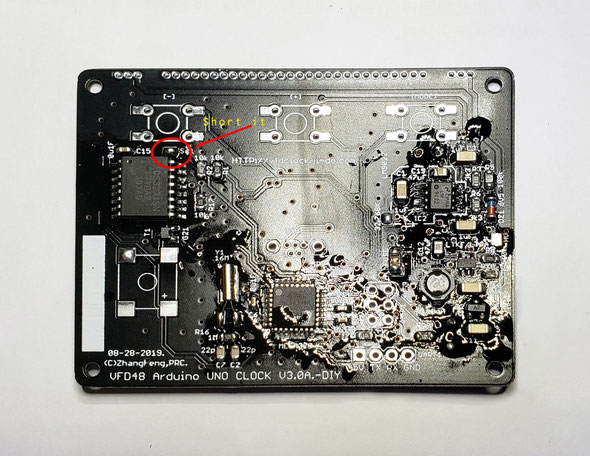

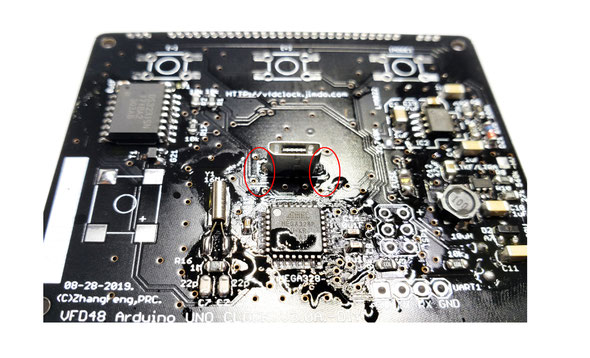

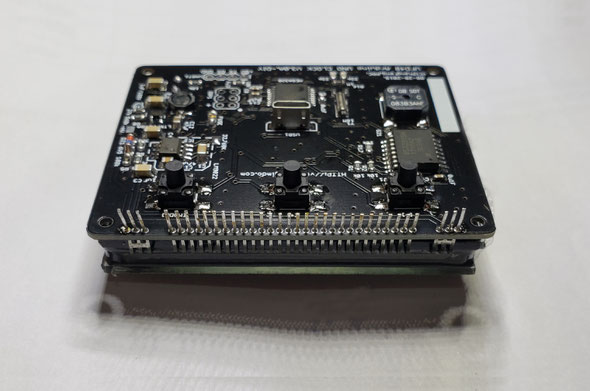

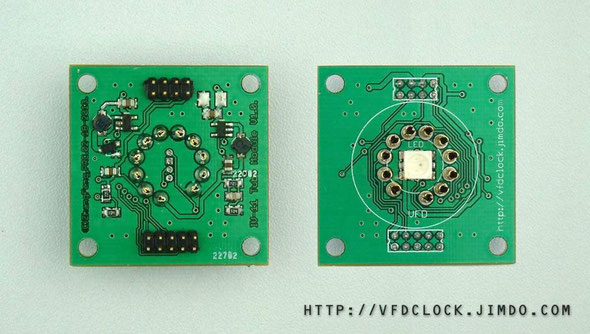

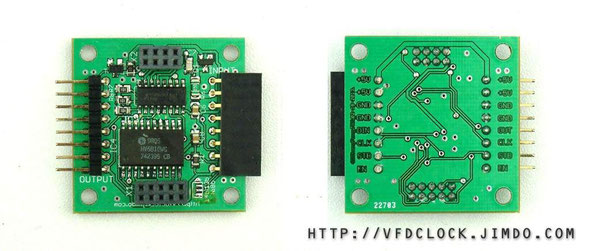

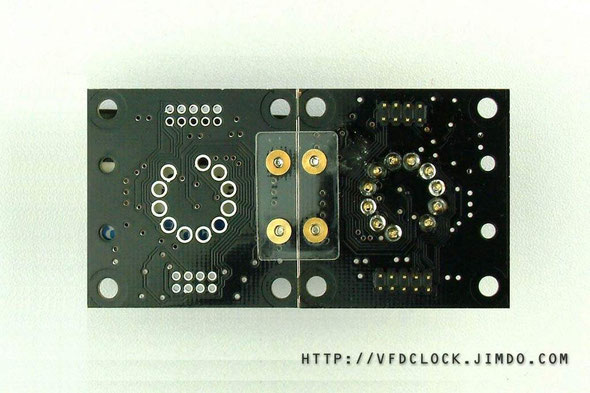

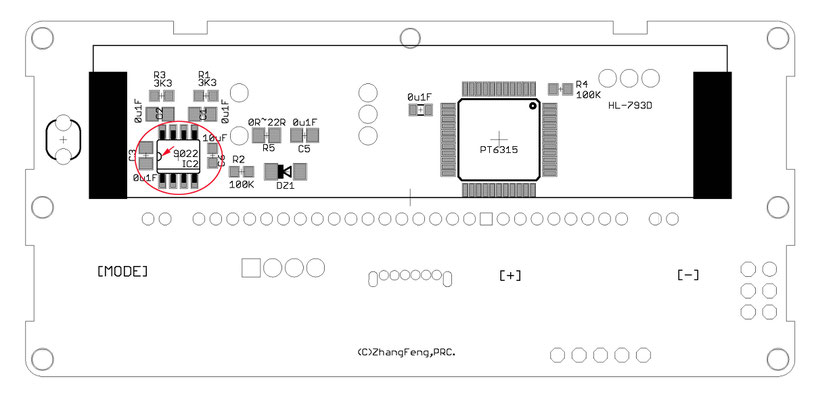

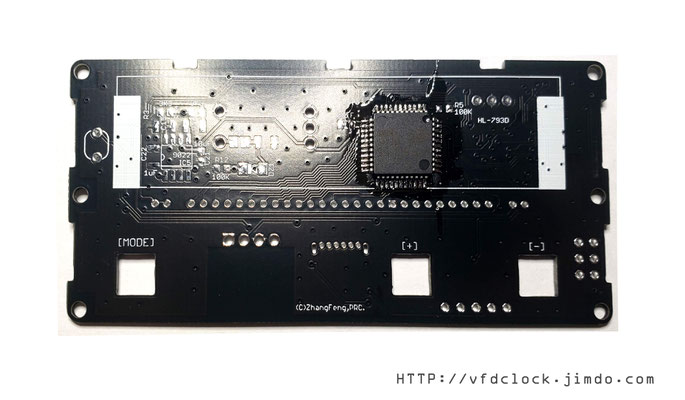

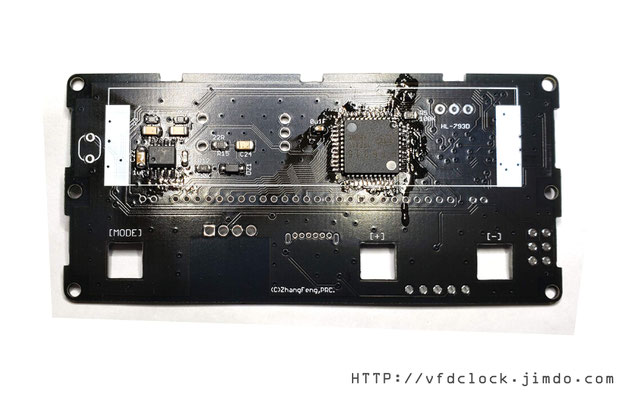

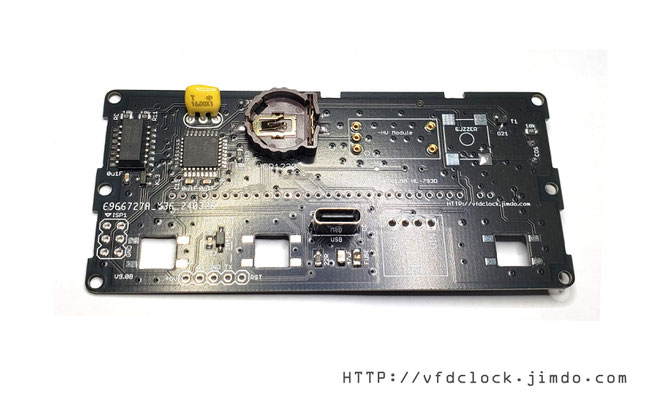

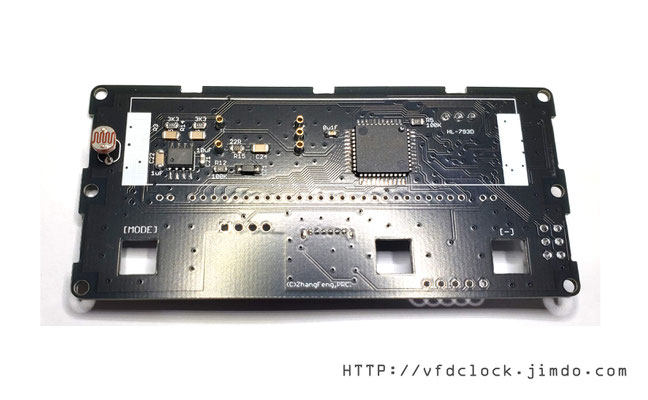

Top and Bottom sides of PCB

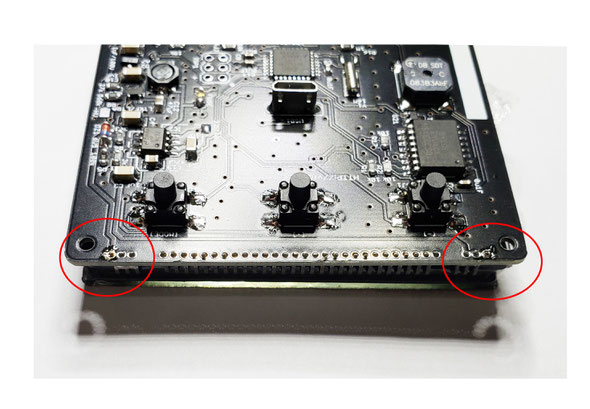

Enclosure assembly instructions

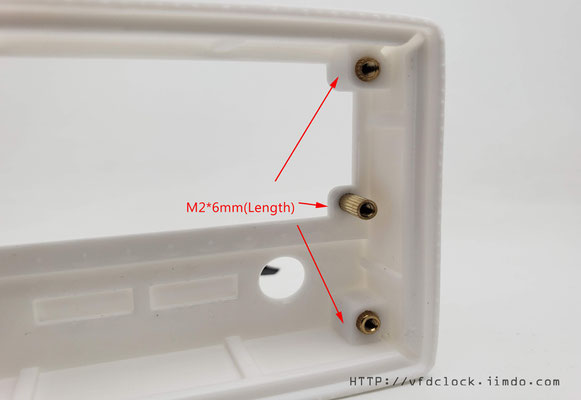

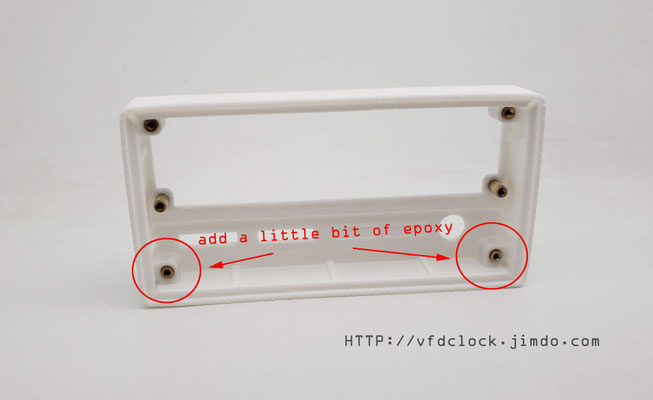

1. First install 6 M2*6mm (length) copper pillars inside the casing. The bottom two need to be bonded into the mounting holes with a small amount of epoxy resin. The remaining four are used on

the front panel of the casing. Screws for fixation;

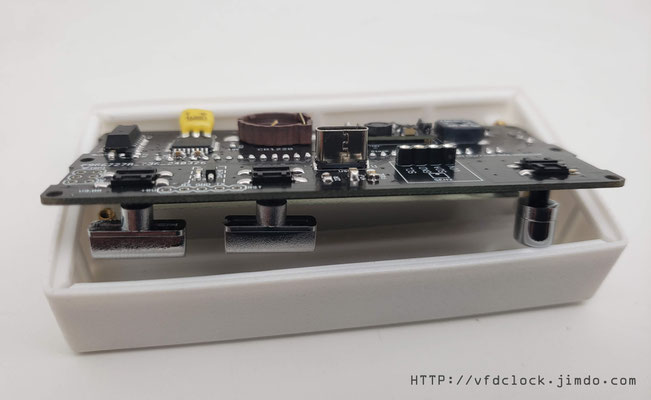

2. Install the key cap on the key, press the key head firmly (please pay special attention to using your fingers or other things to support the bottom of the key when pressing to prevent it from falling off the PCB), and adjust the approximate position of the key cap. Then tilt the PCB into the case until it is in place. Please pay special attention to the fact that the key cap needs to be exposed from the front mounting hole; (Tip: If necessary, consider using a small amount of epoxy resin on the back of the PCB to stick the keys to the PCB. Prevent the button from detaching from the PCB due to excessive pressing force that may occur during use);

3. We recommend first using foam double-sided tape to stick the VFD screen to the PCB, then put the circuit board into the housing and place it in a good position, and then install the fixing copper pillars (M2*5mm ( Body length) + 3mm (screw length)) and screws. It is recommended to use tweezers to clamp the inner hole of the copper pillar for rotational installation;

4. Install the front panel. First remove the protective film on the front panel. The protective film may have multiple layers. The last protective film on the front can be left until the final installation is completed and then removed. Use double-sided tape to install the front panel in place. Depending on the version Different, the front panel may have up and down installation directions, please pay attention;

5. The last step is to install the back panel. This part is relatively simple. You only need to remove the protective film of the back panel and then use screws to fix it in place;

6.Here is the final fully assembled VFD clock.

User Application Instructions

In editing...

Wed

17

Jan

2024

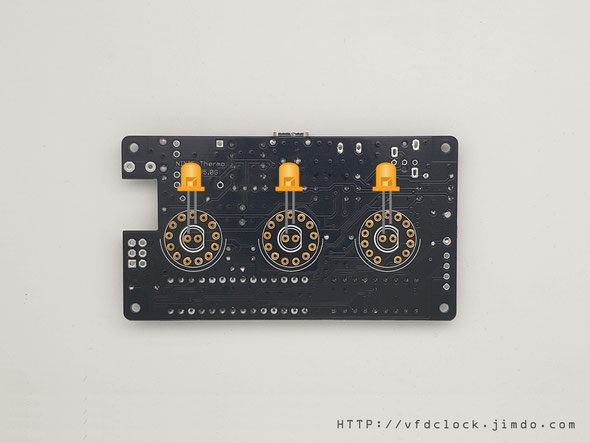

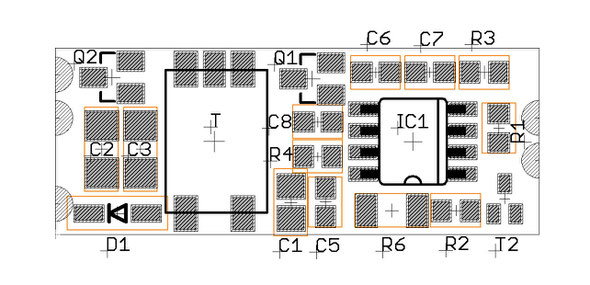

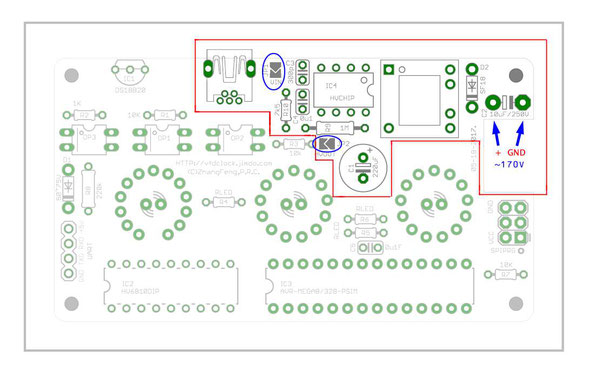

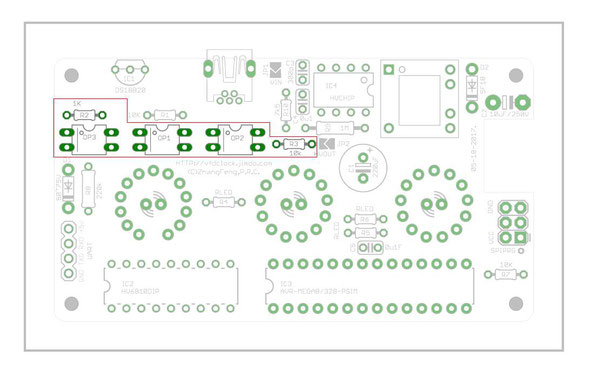

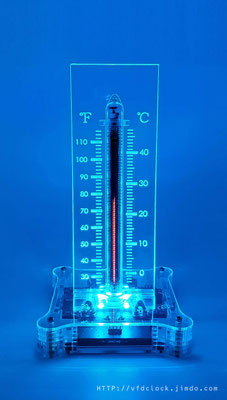

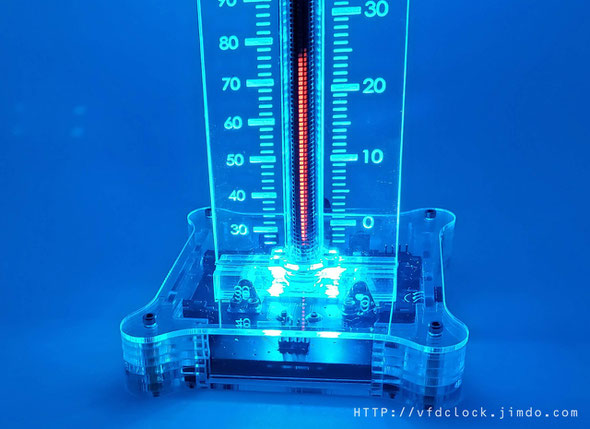

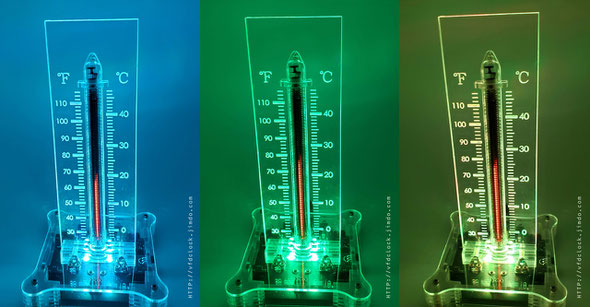

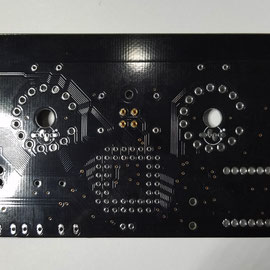

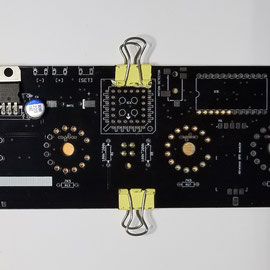

Open Source-DIP-USB Powered-Arduino NIXIE Thermometer-V2.0

This is the 2.0 version of 3 tube NIXIE thermometer, in this version,we move the USB socket to the middle back of the PCB,and added an 3.5mm female socket and a button(to turn the LED ON/OFF).

The oC and oF version use the same source code by adding an C/F jumper on PCB.

(Short the [F] jumper to select the oF version,left it open to select the oC version.)

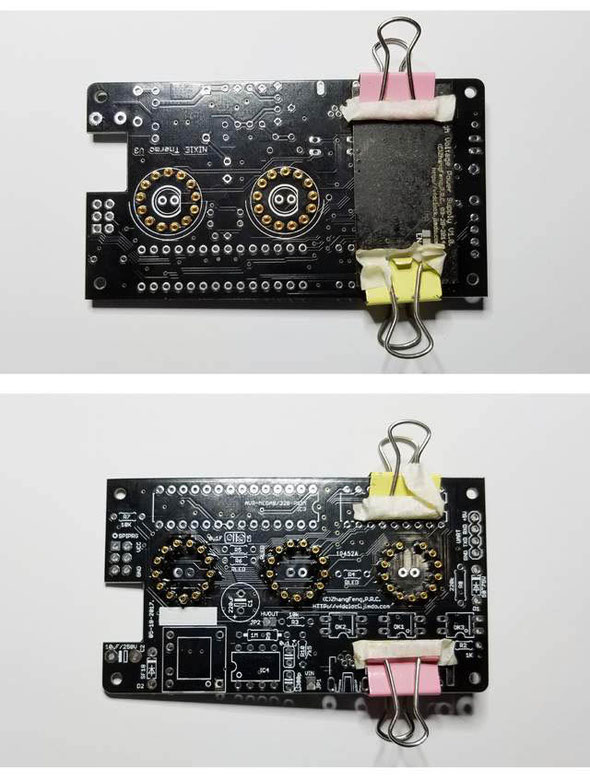

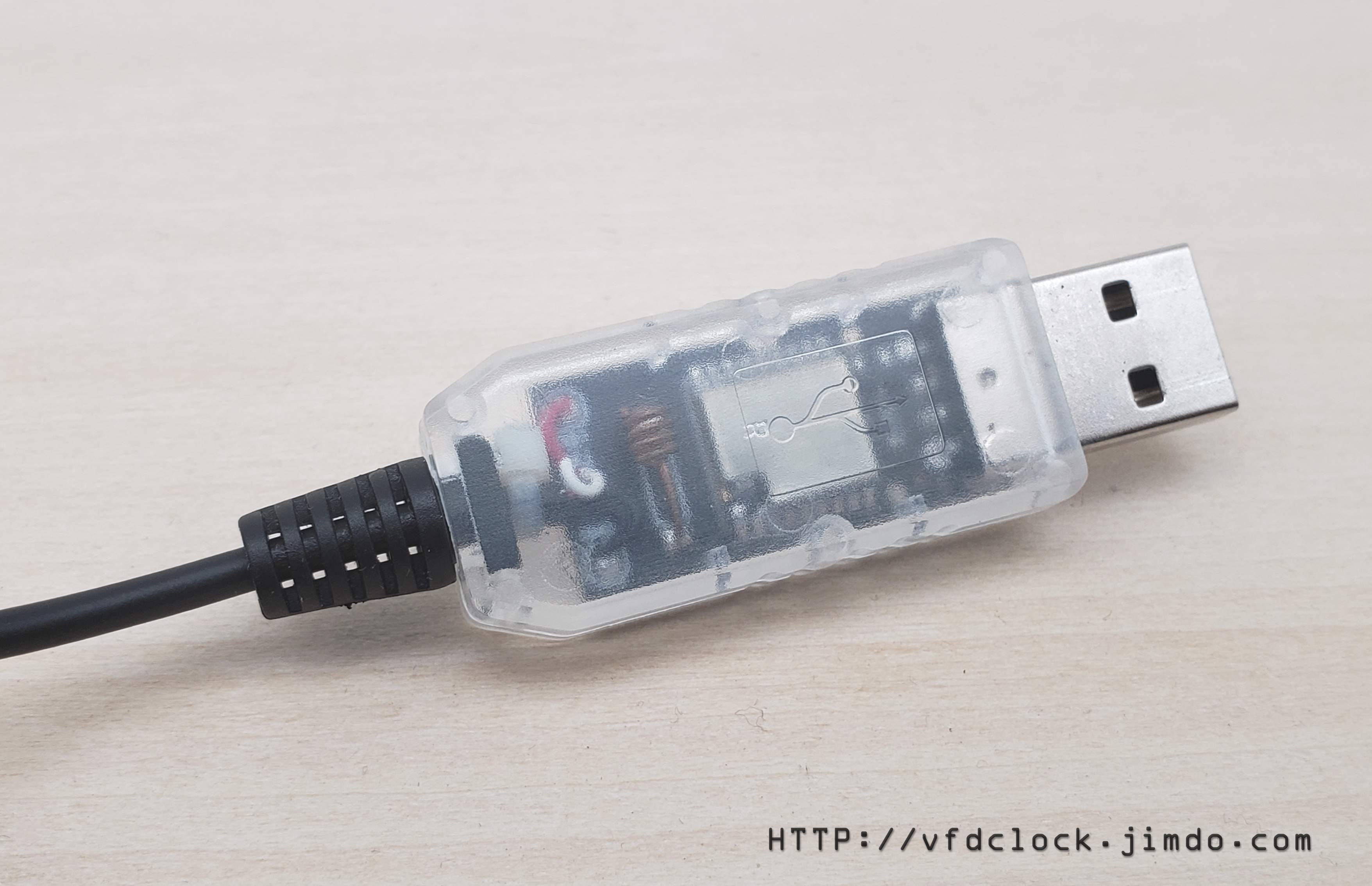

Solder the female through hole pins first.

1. plug the pins on the TOP side of PCB;

2. cover a PCB or hard board on the top of PINS and hole it on PCB by using foldback clip;

3.Flip the PCB then solder the female pins;

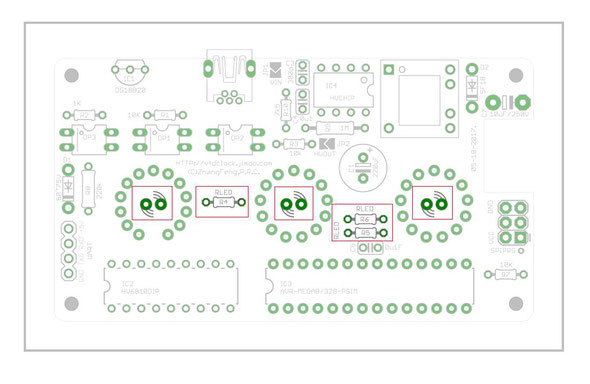

In this version,we added 2 middle female pins to install LEDs, you can replace the LEDs by yourself by hand.

We add orange color LEDs we customized from factory in default, its colors are very close to NIXIE color. If you wanna another colors of LED,you can replace it by yourself. Most of the std. 3mm and 5mm dia. round LEDs all fit with the socket.

Solder the rest of the equipment on PCB as shown on the pic.

Aware the IC socket directions and remember to solder the VIN and HVout 2 jumpers.

In this new version,we add a jumper on the right-bottom of the PCB with MARK [F],if wanna display temperature in oC, left this jump open,if need to display in oF version,please short this jumper.

Do not solder the HV cap and transformer and 3.5mm audio socket and button,those equipment can not be washed.

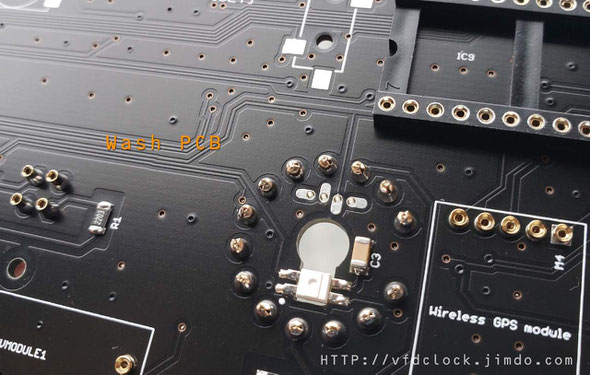

The 2 pics be shown up are the PCB been washed. You can zoom the pics to compare with your PCB to see if all the equipment are be installed correctly.

When done, wash the PCB and make it dry.

When PCB be washed and dried,you can solder the transformer and button,.

for the DS18B20 Part,you can solder it on PCB directly,and if you wanna install it in a 3.5mm audio jack ,you can solder a 3.5mm audio audio socket on PCB.

For how to create a DS18B20 sensor in a 3.5mm audio jack,please visit:

Create a DS18B20 sensor in a 3.5mm audio jack

Plug the LED on the top side of the PCB.

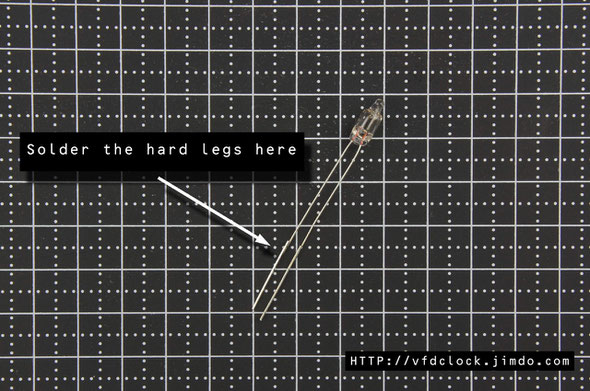

For LED part,recommend cut the legs short first,and aware the LED [+]leg and [-] leg.

Then plug the nixie tubes in the socket.

For oC version,you need to prepare:

2pcs IN14+1pcs [IN19A ИН-19A] NIXIE tubes;

For oF version ,you need to prepare:

2pcs IN14+1pcs [IN19B ИН-19Б] NIXIE tubes;

When done,Plug 3.5mm audio jack DS18B20 Sensor in the socket, then plug USB power, if all fine,the NIXIE tubes will display the temperature data after ~2 seconds.

Assemble the Acrylic enclosure

In editing.............

Wed

17

Jan

2024

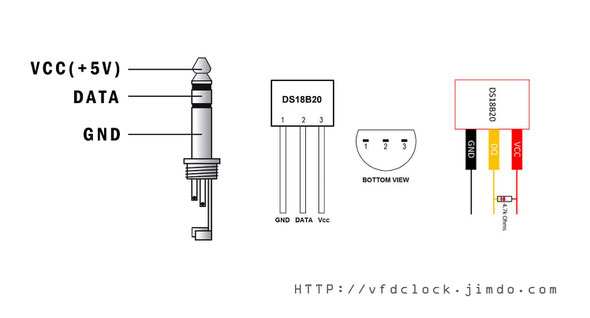

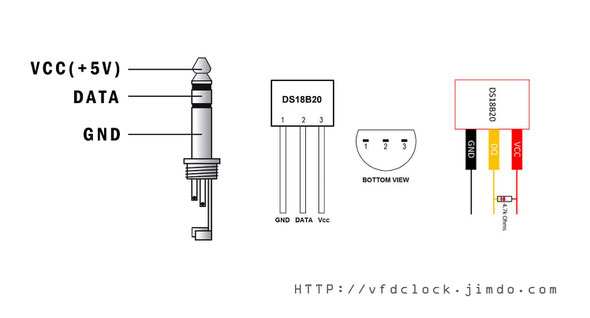

Create a DS18B20 Digital Temperature Sensor with 3.5mm Audio Jack

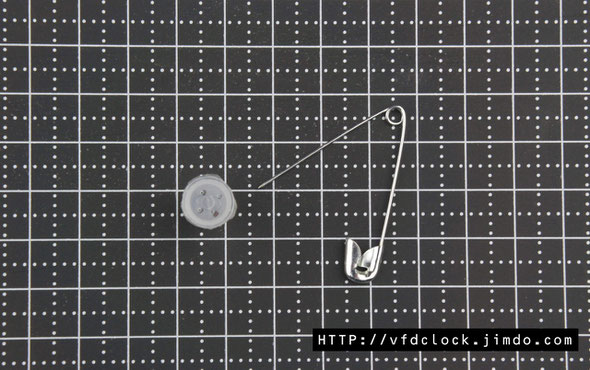

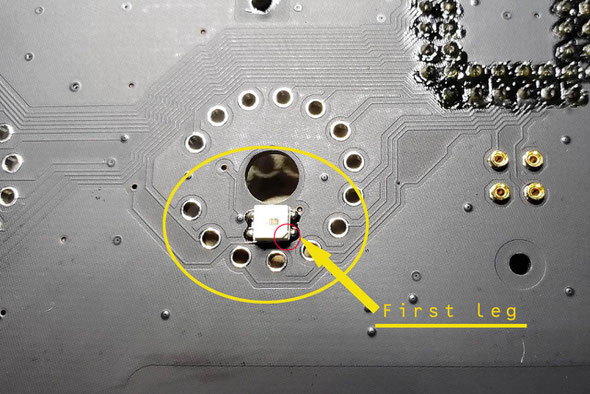

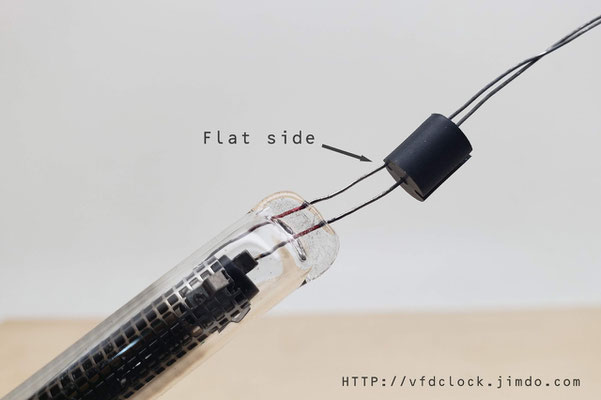

Hold the DS18B20 Digital Temperature Sensor with the 3.5mm Audio Jack Sleeve as the direction showed on the pic.

The circuit connection shows on the up pic,the 4k7~10k pull up resistor is optional.

Band the first leg of DS18b20 up to the sleeve as GND pin.

band the middle pin and plug it to the middle pad of audio jack.

Cut the third pin short and plug it to the short&middle hole of the audio jack.

Solder all 3 pins like as shown on the pic.

Pull up resistor is optional,if need,u can solder an 4k7~10k resisitor between VCC pin and DATA pin.

Plug the PVC tube on.

Done!

Tue

09

Jan

2024

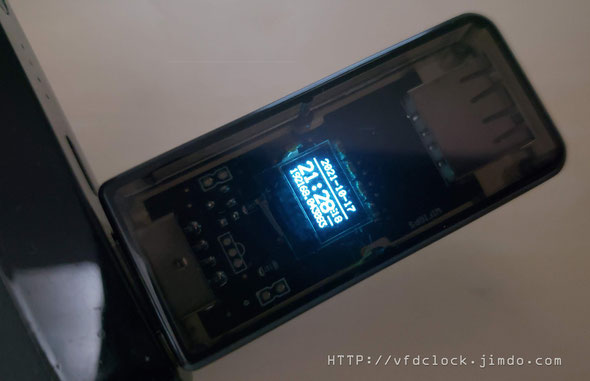

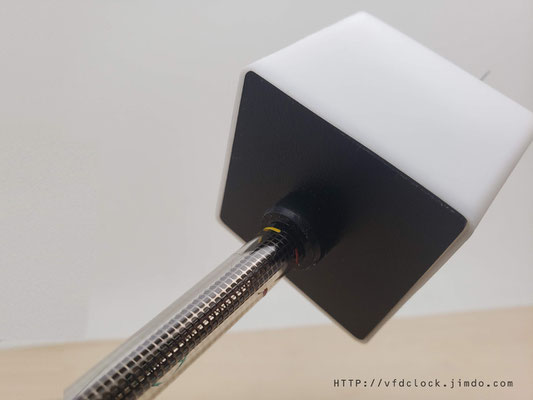

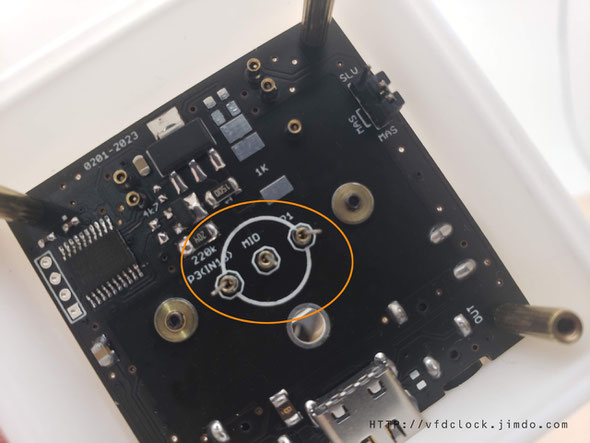

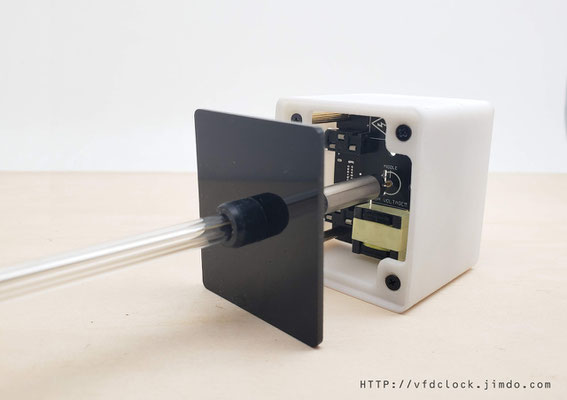

Open Source Arduino VFD Clock With ABS-Like Enclosure

A New design of VFD clock with ABS-Like enclosure.

in editing...

Assembly Instructions

You need to have ability to soldering the SMD equipment to do assemble this DIY KIT.

We use ...

Enclosure Assembly instructions

in editing...

Wed

20

Dec

2023

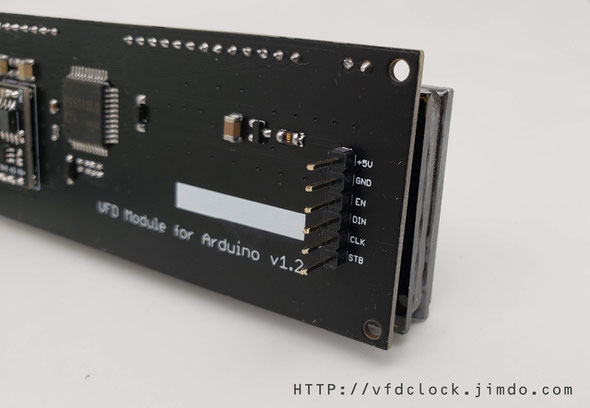

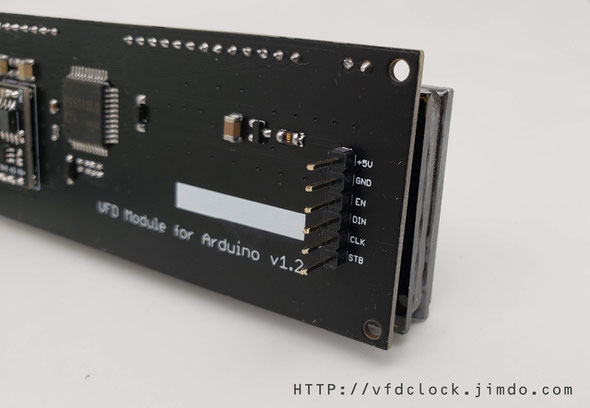

5V Ready-HL-D022 VFD Module for Arduino/Stm8/Stm32 etc.

This is VFD display module only,you need to do the audio circuit part by yourself.

HLD022.ino

Source code for driving the HLD022 VFD module.

Arudino 1.0.4

#define DIN_PIN 13

#define CLK_PIN 12

#define STB_PIN 11

Please use Acrobat Reader from ADOBE to open this PDF file and save the code.zip.txt file from attach part then rename it back to code.zip,decompress it by winzip,7Zip,winrar etc.

Please use Adobe Acrobat Reader to open it,you can find the source code zip file in the attach part of PDF.

Mon

09

Oct

2023

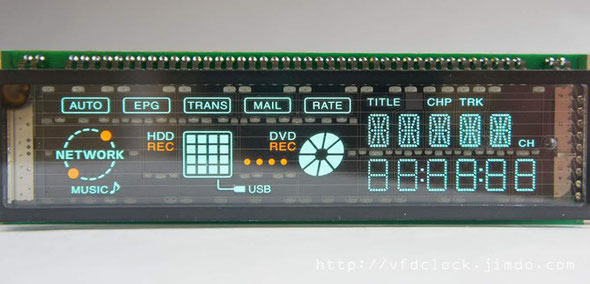

5V Ready-Futaba FUTABA-7-bt-317NK VFD display module

5V ready -FUTABA-7-bt-317NK VFD display module for Arduino;

Please note:

The first grid of a dot matrix can display few defined icons only, it is not a common dot matrix!

Compiled under ARDUINO V1.0.4 in pure C code.

Please use ACROBAT reader from Adobe to open the PDF file and find Source code files in attachments part of PDF.

You can find the password of PDF inside the parcel.

In editing.....

Specifications(For reference only)

VIN:5VDC/~150mA

Panel size: mm* mm

PCB size: mm* mm

Color: Green+ orange

Driver Chip: PT6315

Features:

1). 5V Ready, easy to be used. Can connect to your ARDUINO UNO board with only 3 signal wires;;

2). High efficiency power circuit, no transformer, no heat, Low HV, very safe, High Brightness;

3). All SMT components, very thin PCB, easy to be drived;

4). Contains over-current protection, and reverse

connection protection circuits;

5). Open source code for ARDUINO NUO, pure C code.

6). Simple 3-wire SPI interface, with EN pin, support shutdown the High Voltage and Filament Supply completely.

Interface:

3-wire SPI:

DIN

CLK

LATCH(CS)

--------------------

+5V

GND

EN - HV supply enable(optional)

For Video:

https://youtu.be/...

Tue

21

Feb

2023

3).USB Powered,IN13 VU Display

Tue

21

Feb

2023

2).USB Powered-PL14 NIXIE VU Display

Mon

20

Feb

2023

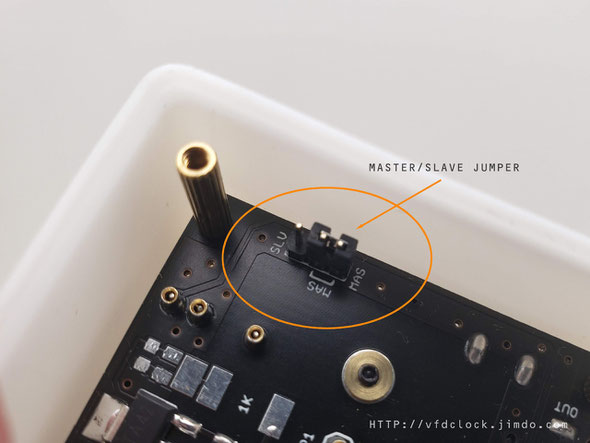

1). Overview :Our VU system

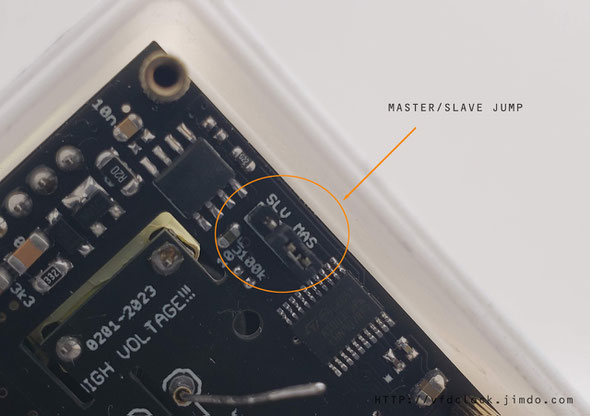

This is stereo VU system,it contain 2 main bodies be connected together by using a 3.5mm audio cable(do not plug audio signal directly via this socket).and set each internal jumper,by shorting the (MASTER) side of jumper,it will display Left channel VU data in default,if short (SLAVE) jumper,it will display Right channel VU data.

tips:The receiver contains swap L-R data button.

There are two 3.5mm audio sockets on the bottom side of Sender,they are same and be connected in parallel,use one to input the audio signal from like cellphone,desket computer,notebook,DVD player,mp3 player,etc.

and use the other one for earphone.

Would please do no connect the signal directly from speaker,may damaged chip inside Sender.

The sender contains 2pcs of buttons on the top,one is (mode) the other is (+).

In normal working mode,when u plug the USB power on,the sender will turn the OLED panel one,and display wireless channel first then display the VU meter of L(on top) and R(on bottom). All others info will be displayed on the bottom row.

You can change the signal gain by clicking the (+) button in -5~+5 range,and use (mode) button to change the smooth algothms in ORG(original signal),STD(standard 50% smooth),AGC1(gain fast,fade slow),AGC2(gain slow,fade fast),BAMBOO(50%smooth,min step set to 5).

How to set wireless channel?

USB power off first,then keep (+) butyon down no release,the plug USB power on,the OLED will display the set Channel info,then click (+) button to change the wireless channel,when done,click the (mode) button,the sender will make a test and save current channel info in flash,then reboot itself(may need 2~3 seconds).

The sender support CH01~CH12 total 12 different wireless channels. One channel signal can be receiver by multi receivers be set in same channel.

test

The receiver contains two buttons on the side,the front one is for setting the wireless channel from CH01~CH12,the top button on for setting the SWAP L-R (left-right) channel On/Off.

When L-R swap on the first Led digi segment will display (').

If receiver gets no wireless signal,the LED Segment display will be turned on,and displays the current channel and L-R swap state, when receives signal,the LED Seg Disp will be turned off.

It may have a small size of LED on the side ,it will go flash when received the signal.

Sun

19

Feb

2023

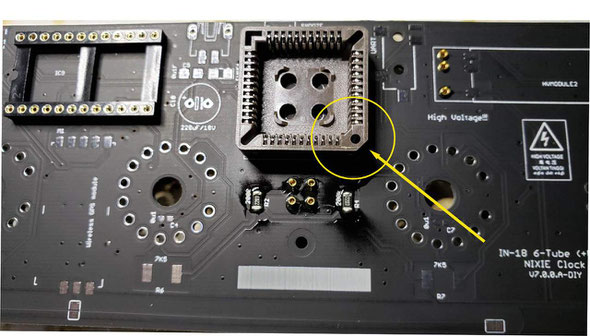

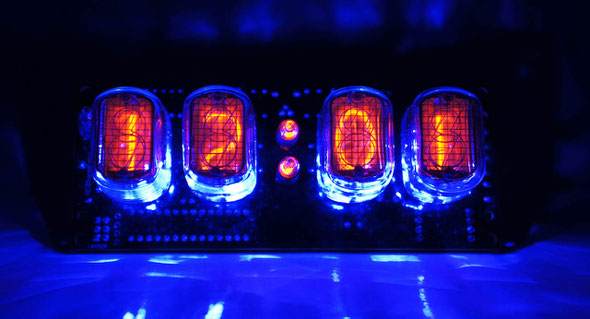

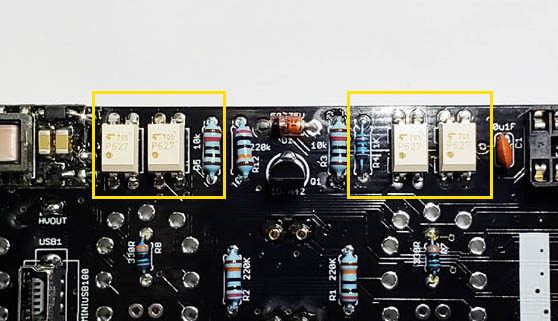

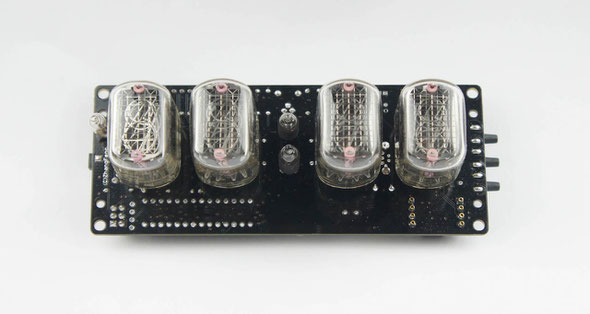

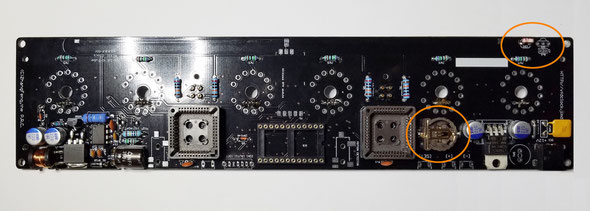

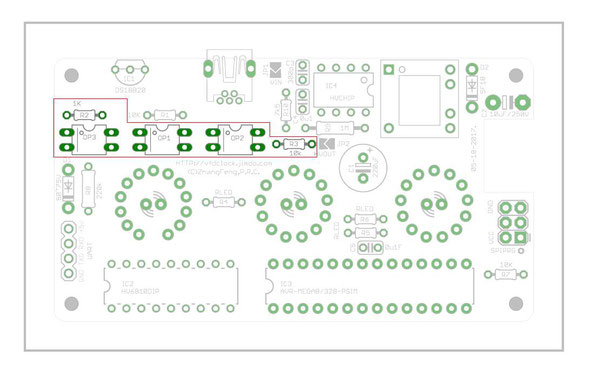

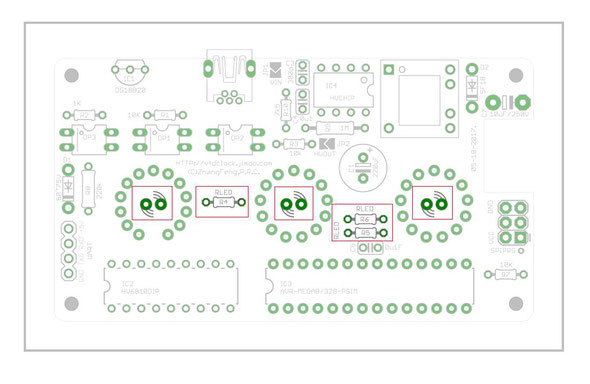

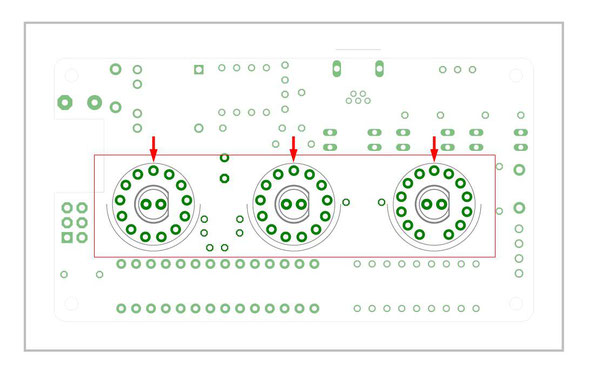

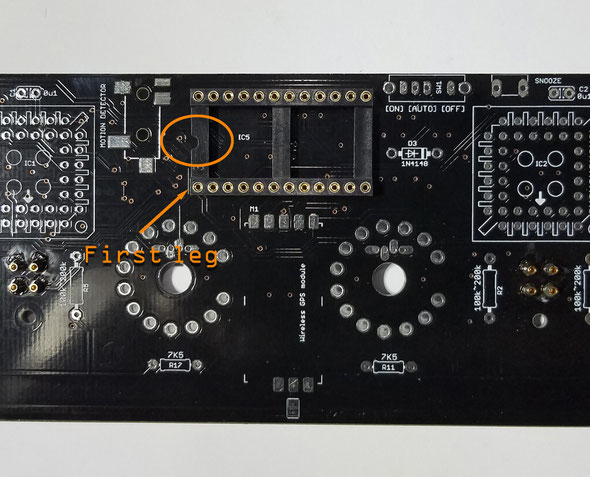

USB powered,IN18 6-tube Clock DIP40 KIT

5V USB Powered-IN-18 6-tube Clock DIY version (DIP40)

Assembly Instructions

V1.0

Notice:

For assembling this NIXIE KIT you need to have the skill of soldering DIP components.

We use a Hakko FX-888 Soldering Station (with CF2 Iron Head). We use 183℃(degree C)low melt temperature solder wire S60, 0.5mm(Dia.), Brand Almit.

And for most of the SMD components are big size and easy to be assembled,if you have a Hot air blower station,will help.

For how to solder the DIP components, we recommend:

https://www.hakko.com/english/tip_selection/type_bc_c.html

https://www.hakkousa.com/video/

Building it

Well, because of the circuit is block based and not very complicated, all you need to do is get all the components in the right position and make sure no short or no float before you plug the

power in. We will show the soldering steps blow.

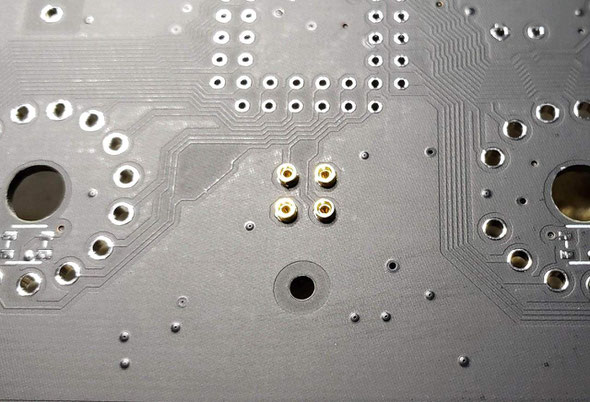

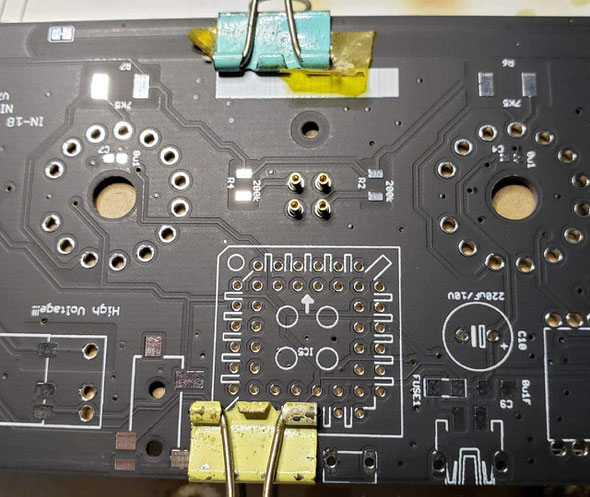

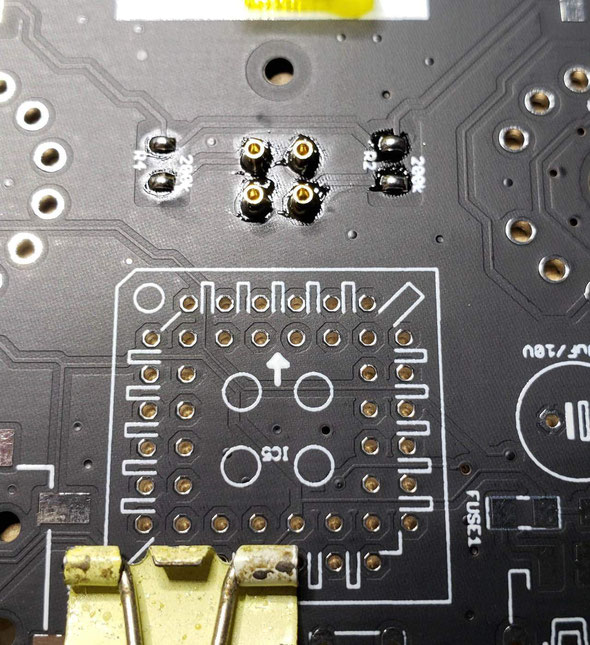

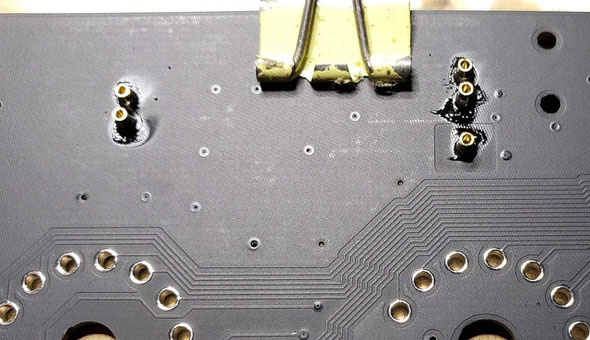

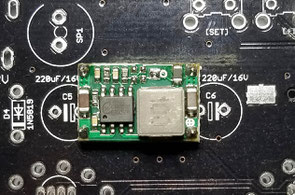

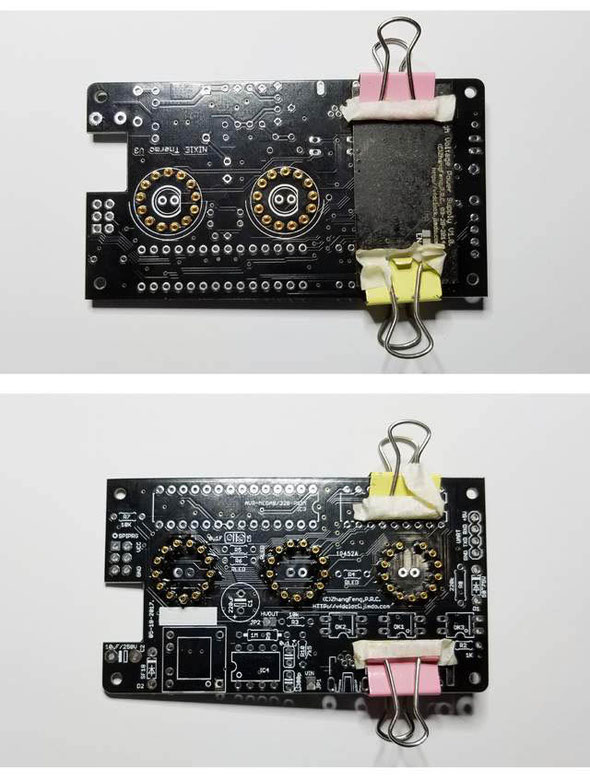

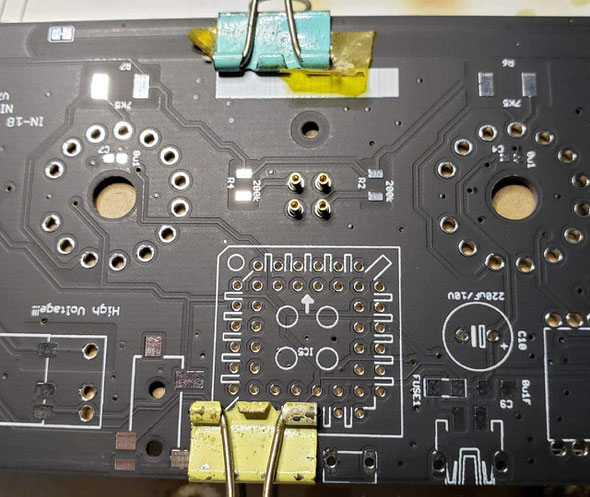

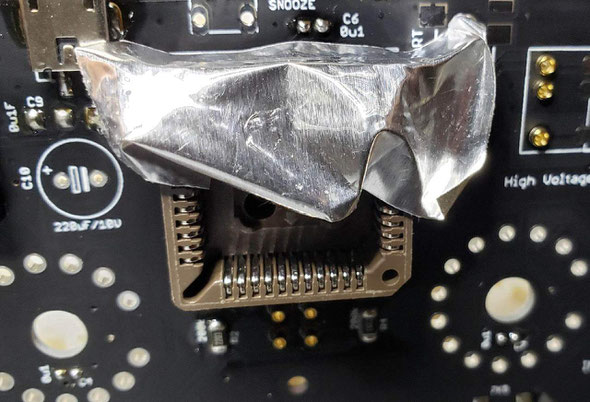

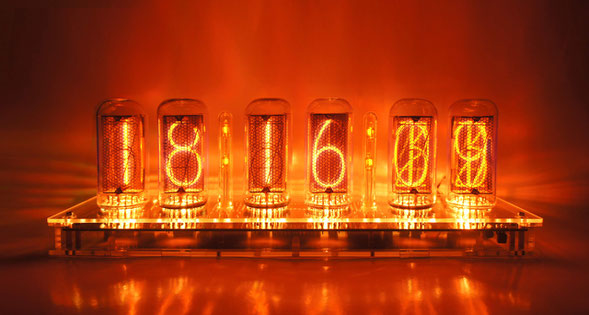

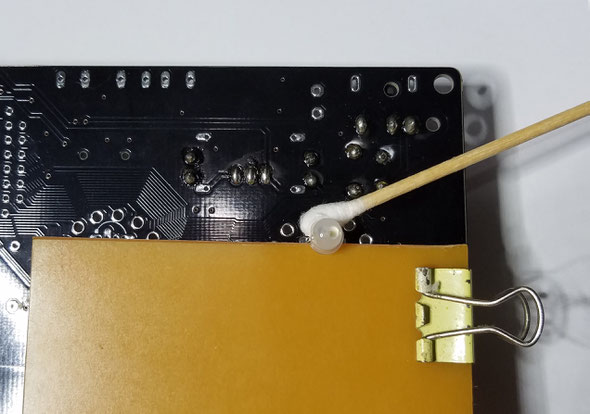

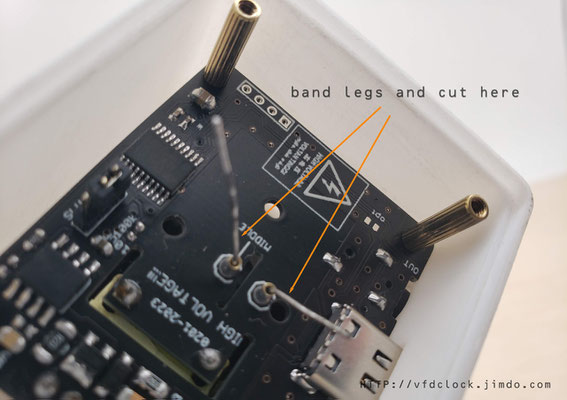

1): HV module Pins and WIFIGPS module PINS(Optional)

We need to solder some pins in this step,please solder it in this step,will be easier to be installed.

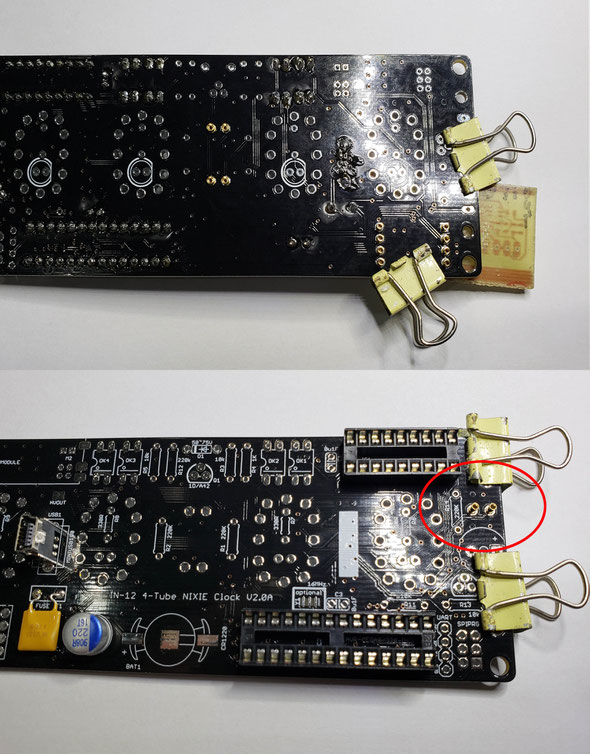

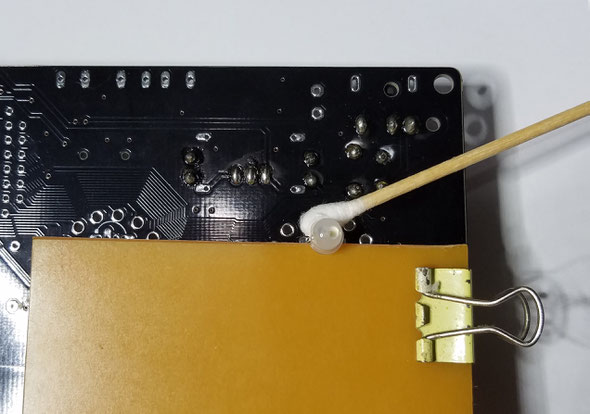

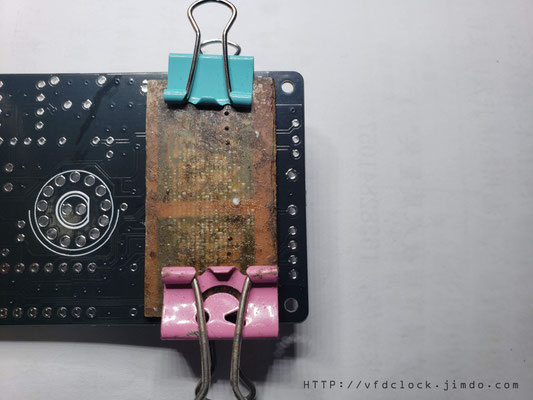

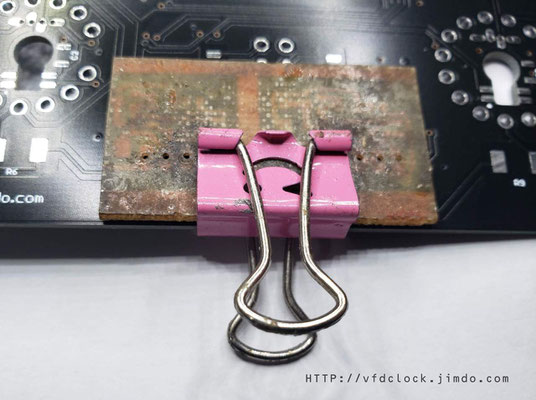

Please plug the Female PINs on the Bottom of the PCB then cover a had board like a small PCB or small

wood board etc.over the PINs, use two clamps to hold it with the main PCB, then flip the PCB. Now you can solder on the other side.

Tips: Because of the PINs are through hole version, please solder it carefully and do not let the tin goes in to the inside of the pins or will damage the PINs. If necessary, you can plug a

wood/bamboo toothpick in the bottom of PINs hole when soldering.

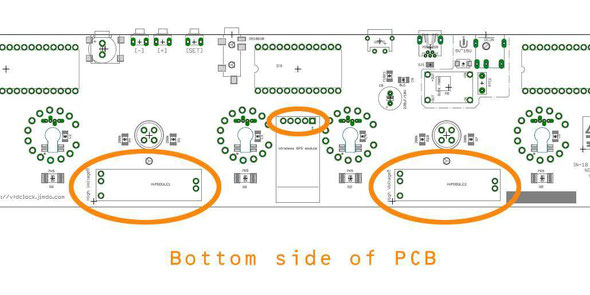

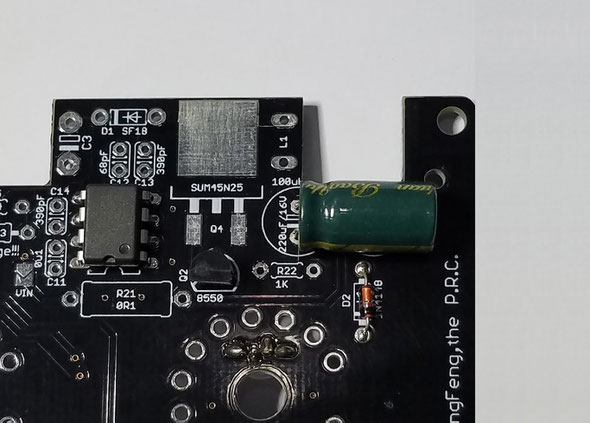

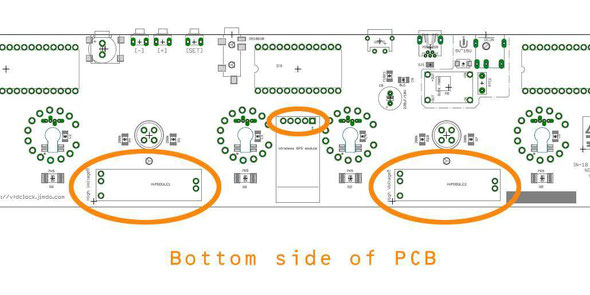

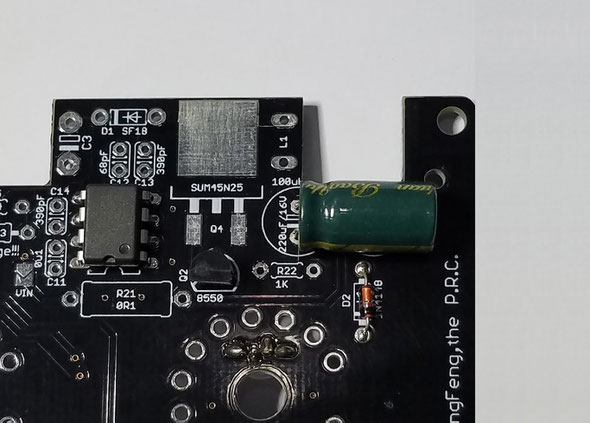

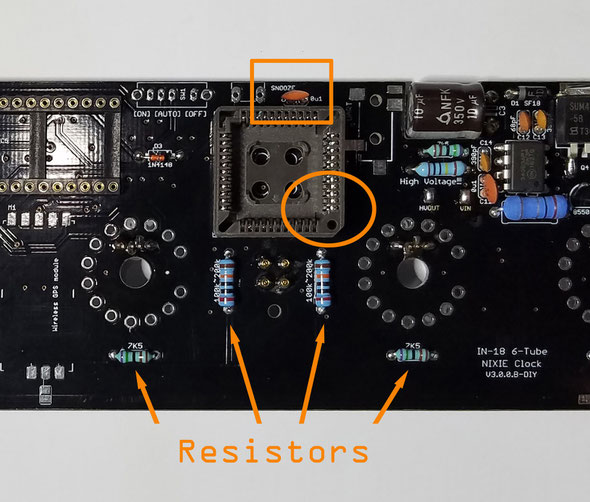

2): Solder the resistors and caps on the bottom side

The resistors are all in big side like 1206 or 2412,easy to be installed,and the caps for LED is in 1206 size.

For caps near LEDs,we recommend solder the caps first if you are using Hot air blower station,or the hot air may damage the LEDs.

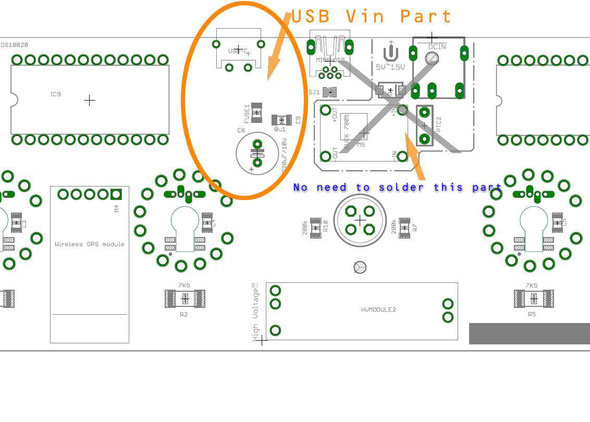

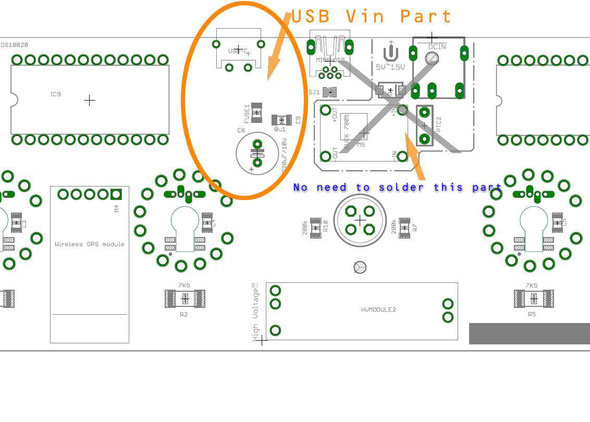

3): Install Main power and others components

The main power part has a USB socket(May in MINI USB/Micro USB/TYPE C,install only one USB socket),and a fuse, a 100nf cap and a Big Aluminum Electrolytic Capacitor(Please take care of it's direction).

No need to solder the 12V->5V buck convert part as shown on pic blow.(This part may not even exist in some of the PCBs, just Ignore it).

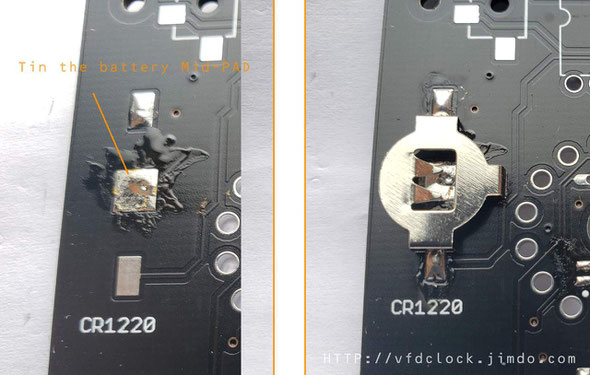

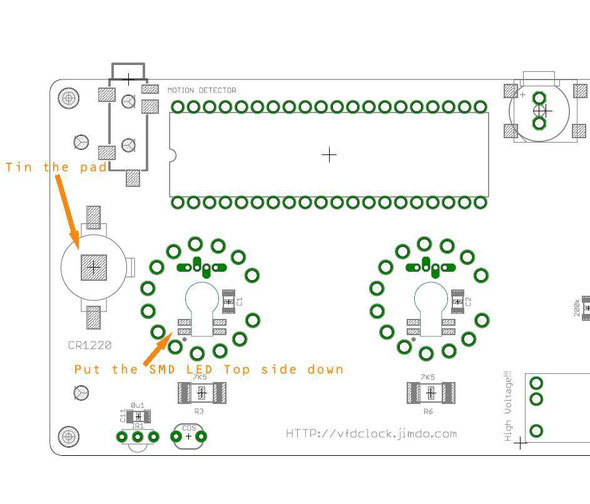

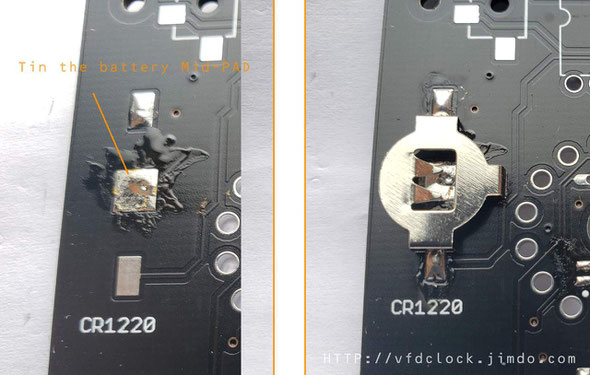

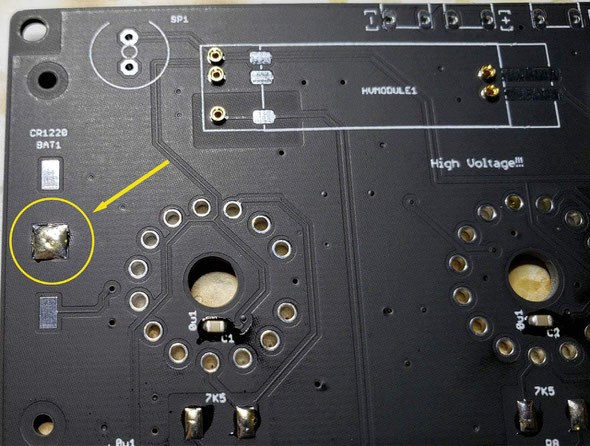

4): Install the CR1220 battery socket

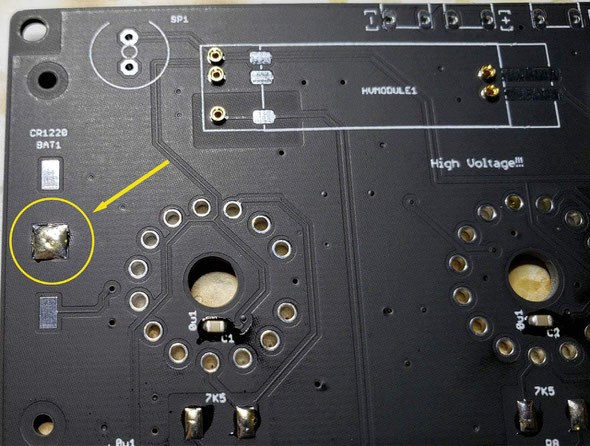

In this part,we need to tin the middle battery pad first,then solder the metal holder,please do not add to much tin on the middle part.

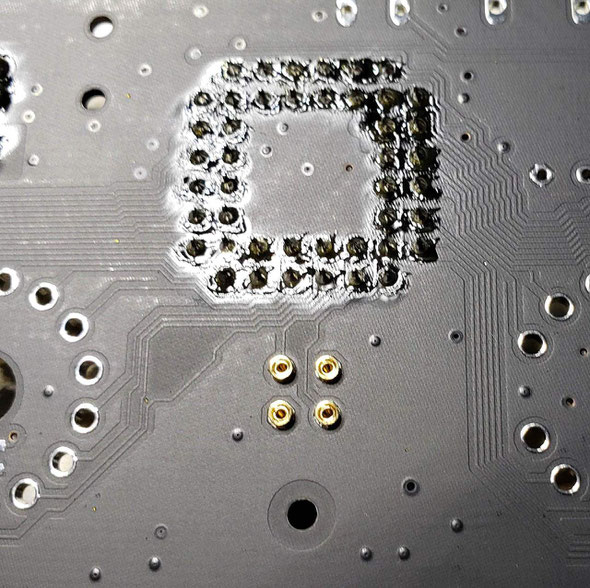

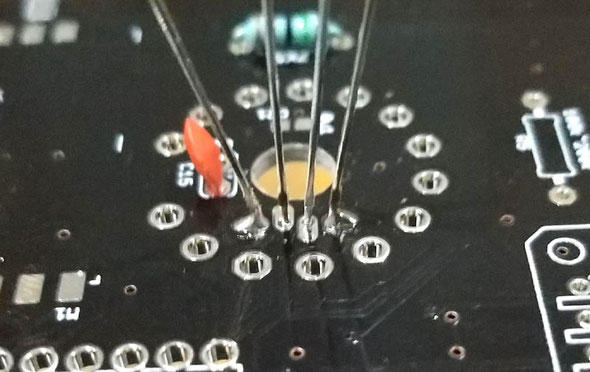

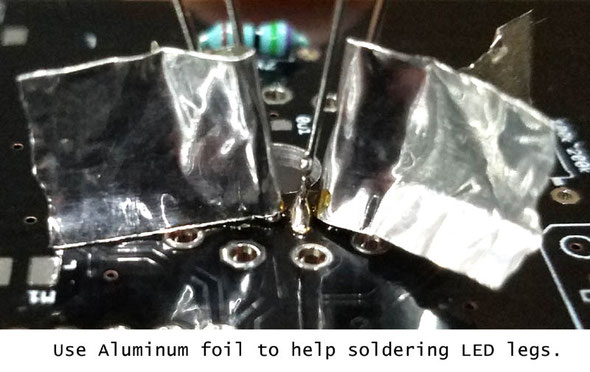

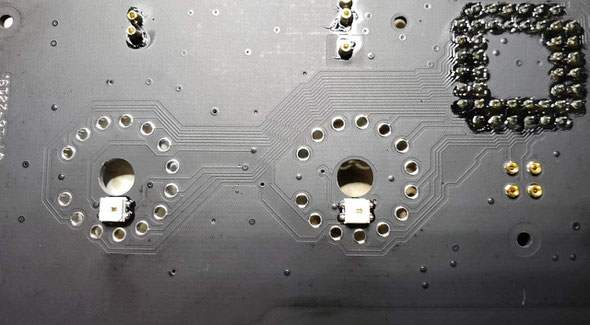

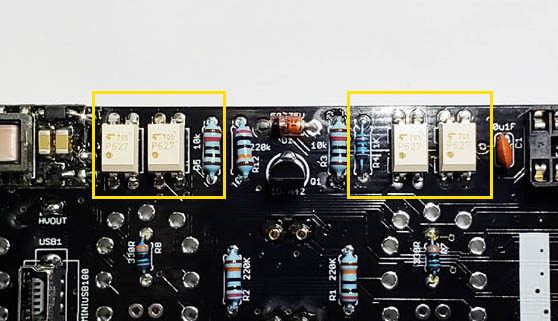

5): Solder all LEDS

May have two type of LEDS can be installed on PCB, one is smd version ,the other is dip version,would please install only one type of LEDS,do not install two types.

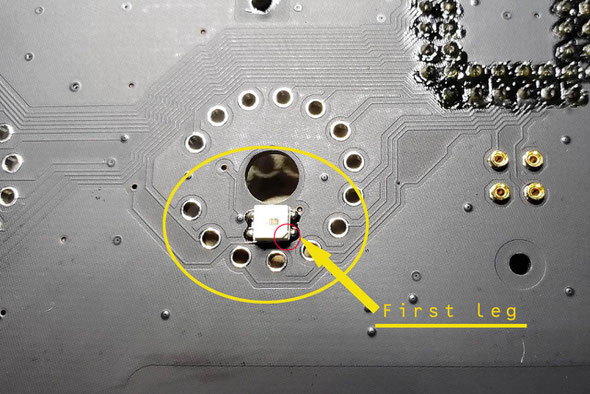

First ,we need to aware the first leg of LED,do not go wrong direction.

Second.LED is easy to be damaged when soldering,we need skills for low down its temperature.

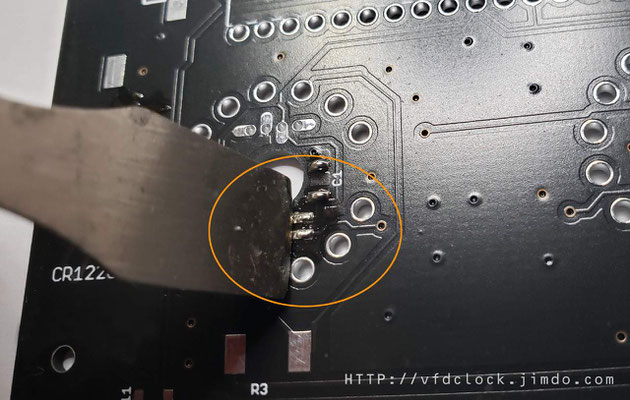

For SMD version of LED,need to use a slim metal stuff to touch its soldering pad as a heat sink. We use a Solder paste scraper as heat sink,you can use utility knife instead if

you do not have one.

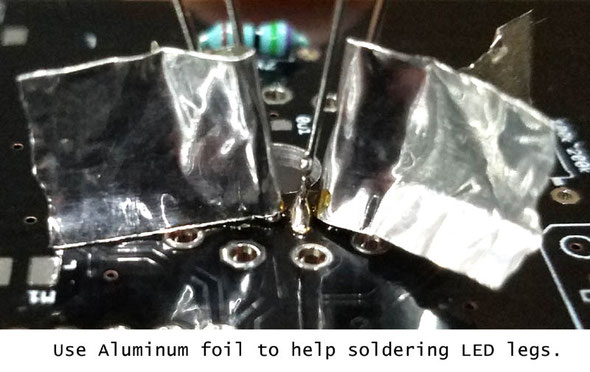

You can use tape to protect the IN-18 soldering holes on PCB when soldering the LEDs.

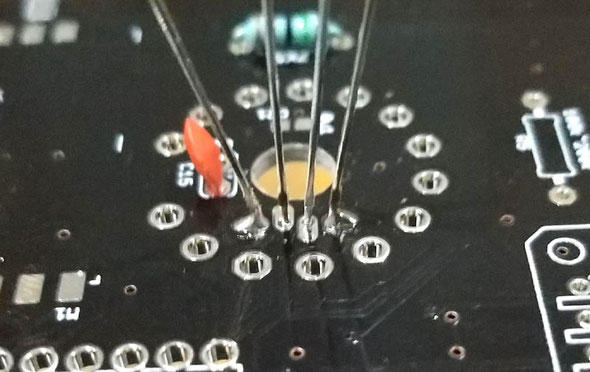

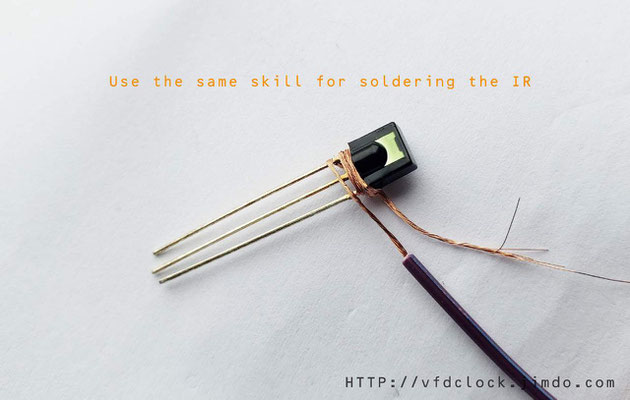

For soldering DIP version of LEDs,Use a bundle of copper wire to wrap around the pin a few rounds as

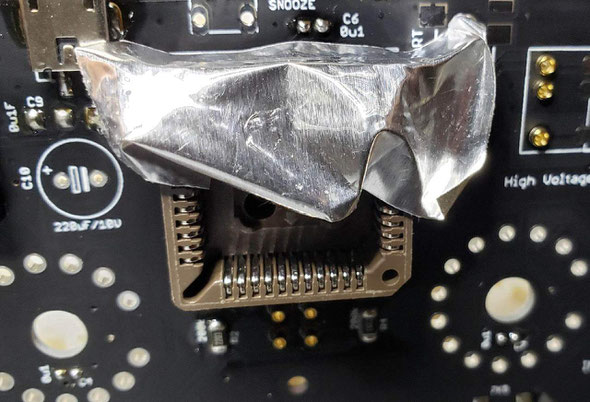

heat sink. Then plug the LED in the PCB and solder it,when done,remove the wire.

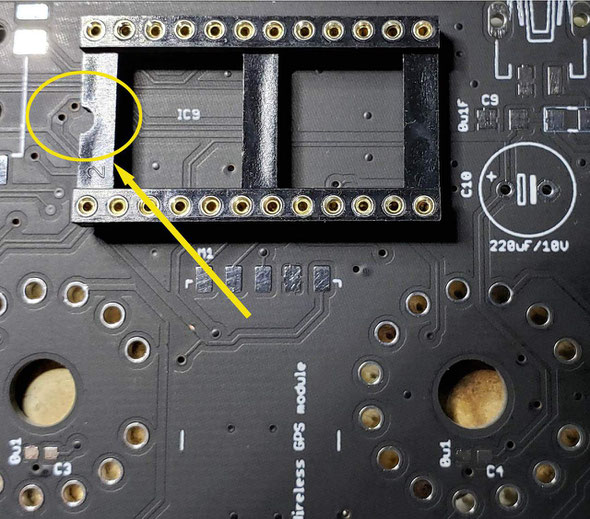

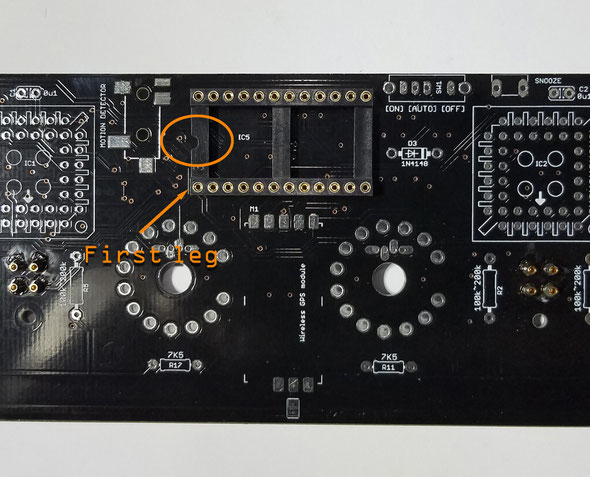

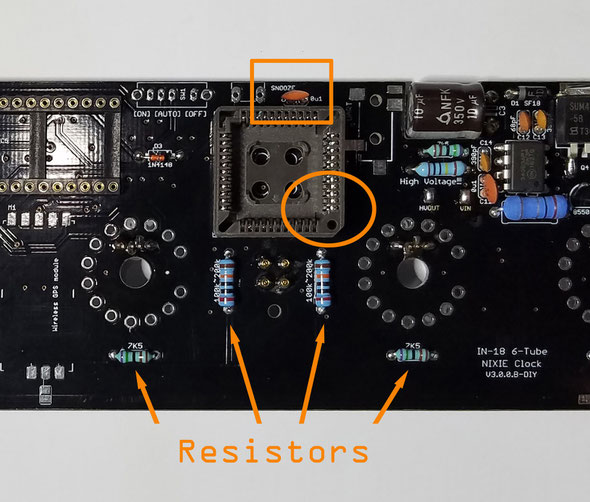

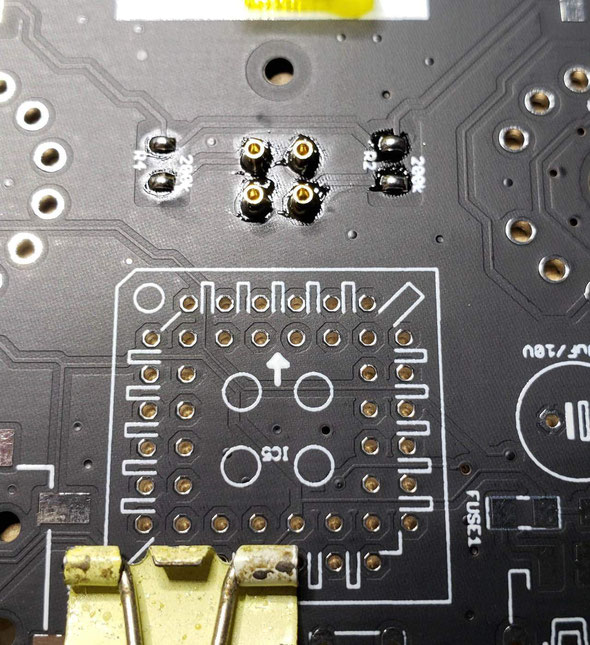

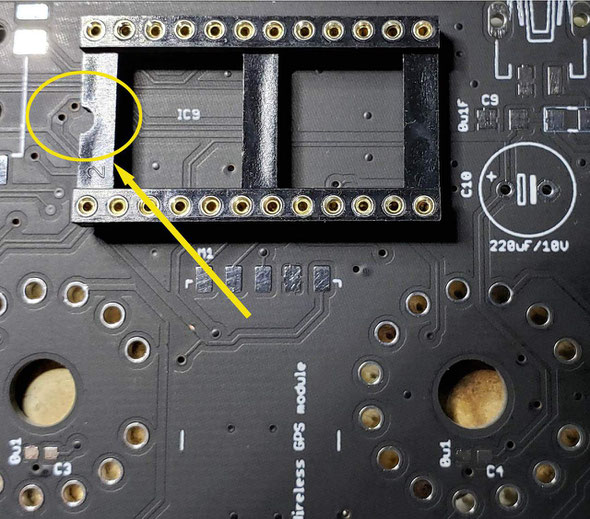

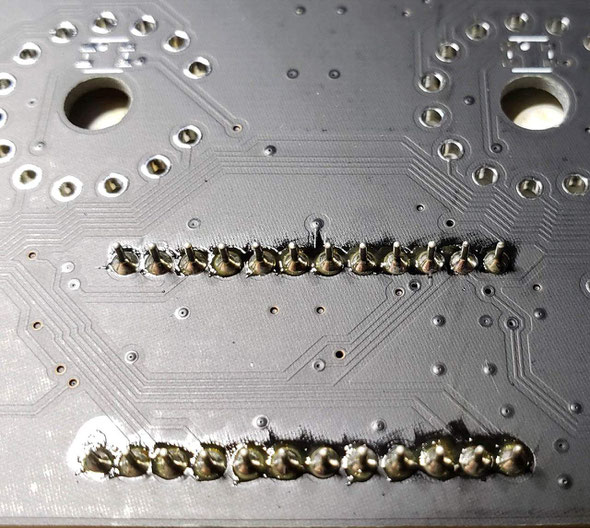

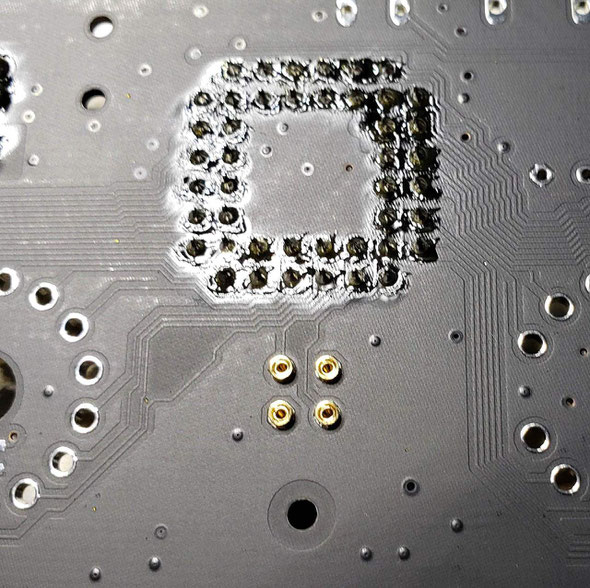

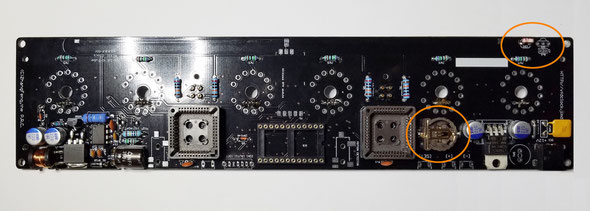

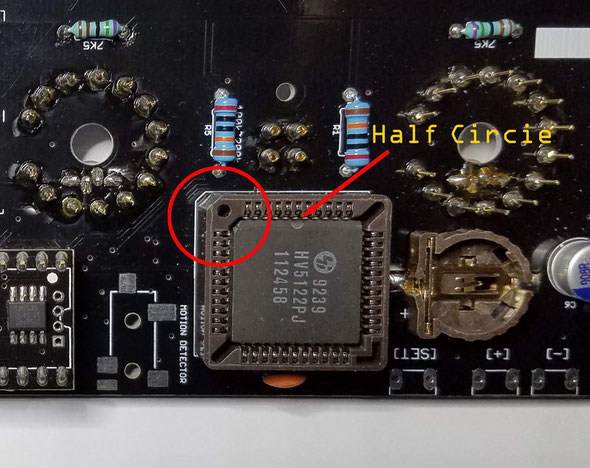

6): Solder all IC sockets

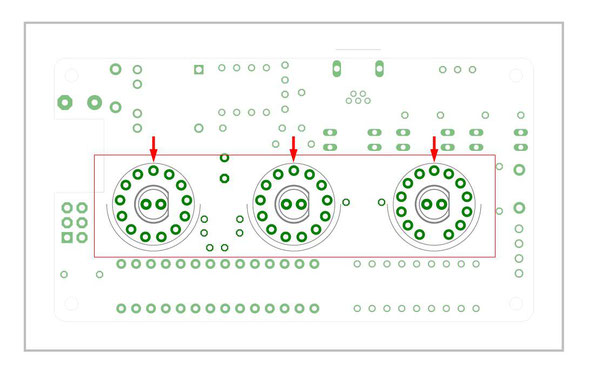

We need to install 3pcs of IC sockets,one is the main MCU module in DIP24 and the others are two DIP40 NIXIE driver module socket,please aware the direction of the sockets ,do not go invert.

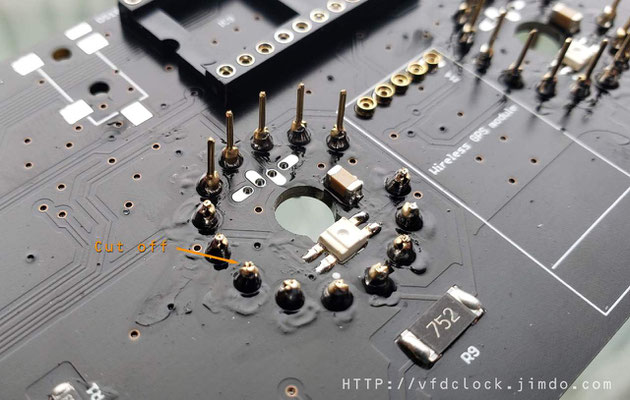

We recommend u cut the thin legs of the socket before solder it on PCB as shown on the pics blow.

7): Solder Middle Colon Pins

The middle colon pins are on the top side of PCB,solder it a u solder the HV-module pins before.

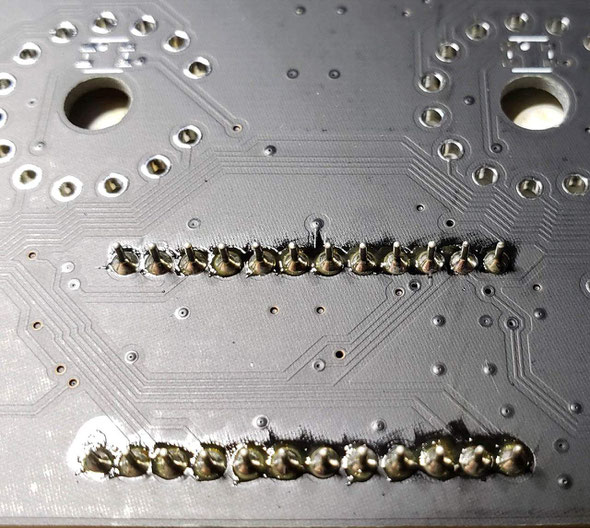

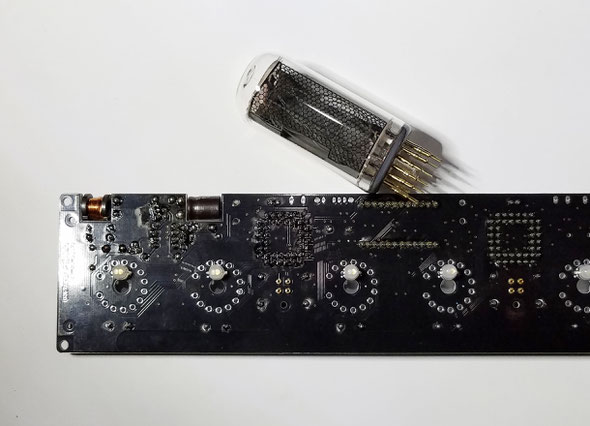

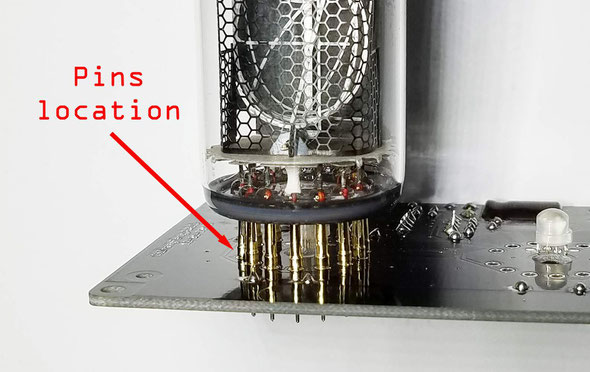

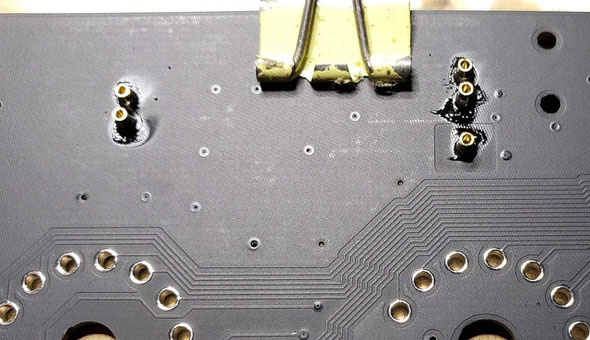

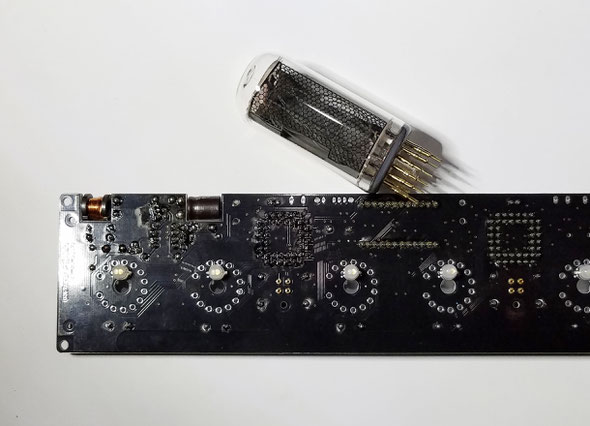

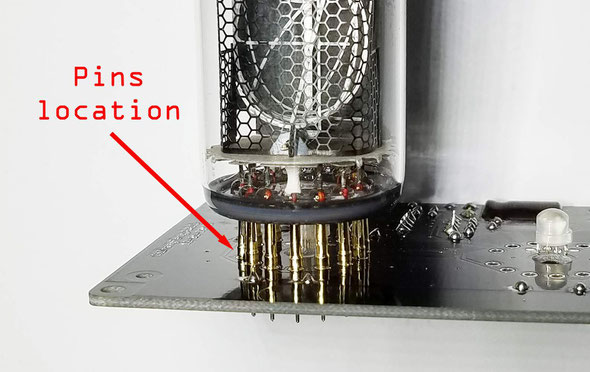

8): IN-18 PINS

Now we are going to solder the IN-18 PINS.Please flip the PCB to the front side,the PINS need to be installed on this side and please solder it on the middle part of the PINs;

First we recommend you plug the PINS in the IN-18 legs,then plug ALL the PINS to the install holds,plug it down to the middle part, then flip the PCB ,solder the PINs on the bottom side of PCB;

!!!Plase double check to see if all PINs are plugged to the middle part before you solder the PINs!!!

In soldering the PINS,if necessary,you need to keep pushing the tubes down to make sure all the PINS have been soldered on the middle part, please trade care of this part.

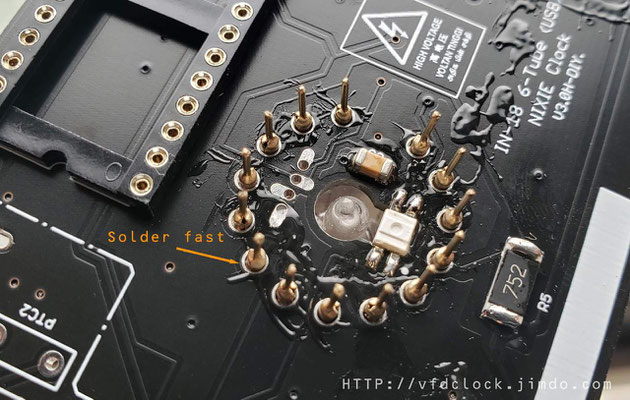

!!!Pleas note, do not add too much tin in soldering PINs,and please solder it fast. If add to much tin, the tin may go inside of the PINs and will solder the IN-18 tube legs with the socket,which will be big problem. We recommend add a little bit body lotion or oil on the surface of all in-18 PINs, will help to prevent be soldered together with socket.

Make A fast testing:

And after finished soldering on tube PINS,give it a power on test(*Remember to plug the MCU module and Driver Modules and HV mpdules in socket for testing) to see if have any problem.

9): Cleaning the Circuit Board

You can use the household rubbing alcohol and a toothbrush to remove the solder flux on the PCB.

If available, the anhydrous alcohol (used for electronics cleaning) works much faster. Blot the cleaned area with a non-linting tissue (like Kimwipes EX-L) or a clean towel or you can do it in your own way.

10): Buttons and Buzzer

Because of Buttons and Buzzer etc. can not be washed, we need to solder 4pcs Keys and 1pcs Buzzer after cleaning the PCB. If the Buttons are one side two pins version,just solder it directly on PCB,if the Buttons are two side 4pins version,cut one side 2 pins off buy yourself,and band it flat the other side of 2pins then solder it and cut it short(or cut it short first before soldering);

Extras :

The IR function is optional,you need to solder the IR sensor on PCB,use the same skill of soldering the DIP LED as shown in the pic.

And is also have WIFIGPS module,you can just plug the module in the middle-front side(bottom) of PCB .

For how to setting the WIFIGPS, please check:

If it has UART BPS menu ,please select :9600bps.

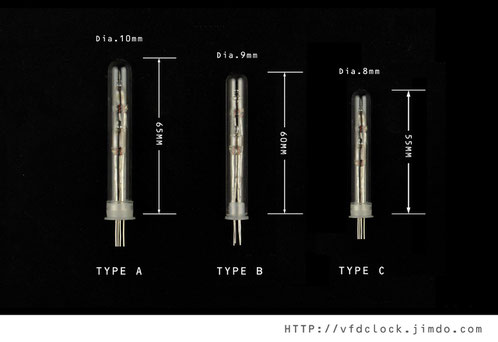

11): Create middle comma

For how to assembling the Middle comma,please visit:

KIT-Create the Middle Dot Comma for IN-18 NIXIE clock

You can make your own decision of the location of the bulbs in the middle glass tube.

The full map of the clock.

Sun

19

Feb

2023

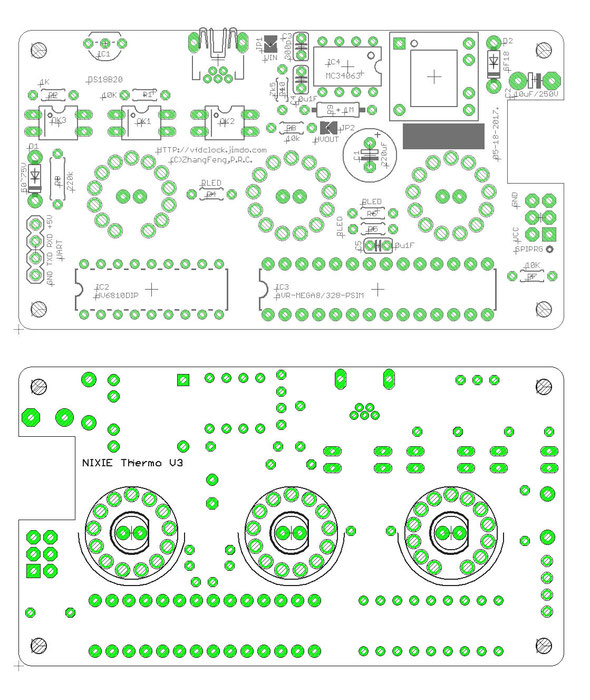

Open Source,3-tube Nixie Hygrothermograph DIY kit

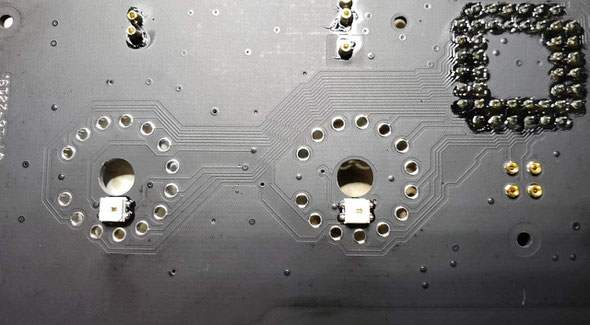

Solder the LED ,plug the LED on the bottom side of PCB,the lighting side face on the top of PCB,sware the first leg of LED as shown on Pic.

LEDs are heat sensitivity equipments, if possible, use 130C low temperature soldering wire,or use a slice metal(the pic shows back side of a paper knife blade) as heat sink,the solder the LEDs,and if possible,protect the nuxie holes by using kaptin tape.

Solder the socked pins of Nixie tubes. First plug all female pins from the top side of PCB,then clip it on by using a small size PCB on the top with a clip.

Flip to the bottom and solder all pins on.

When done

Solder the HV module 5 pins female sockets.Same clip on skill.

Solder the I²C 4-pin socket,big glass diode,16M resonaror(both mounting directions are all ok) and the USB socket.

Solder all the IC sockets,aware all the sockets direction.

Then wash the PCB to make it clean.

Solder the 3.5mm audio socket and button. These two equipments can not be washed.

Plug all the ICs and OP modules and HV3W DC-DC module and the sensor(face top).

Solder 4-pin male pins on the top of sensor module.

Tue

21

Dec

2021

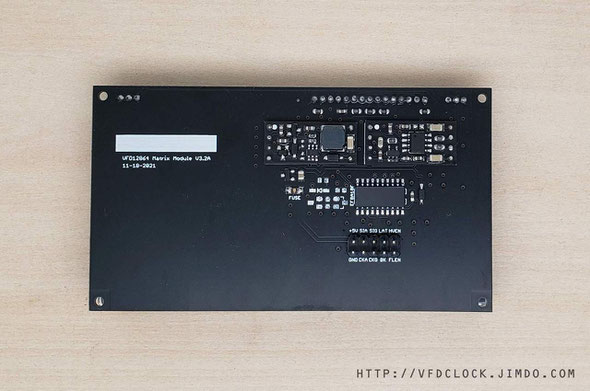

5V Ready-VFD128*64 Dot Matrix Module for Arduino UNO

In editing...

VFD dot matrix 128*64 display module Features(For reference only)

1. 5V main power ready, 5V/3V3 IO part;

2. Support Arduino UNO , pure C source code;

3. Global brightness adjustable;

4. Module Based driver board;

5. Self protect scanning circuit with input inverse protection;

Size: mm;

Weight: g;

Power: 5V main power(5V/3v3 for GPIO);

Current: mA;

Fri

22

Oct

2021

USB-WIFIGPS OLED Version-Sync time with NTP server via WIFI

[For reference only]

In this guide you’ll learn how to config and use the WiFiGPS.

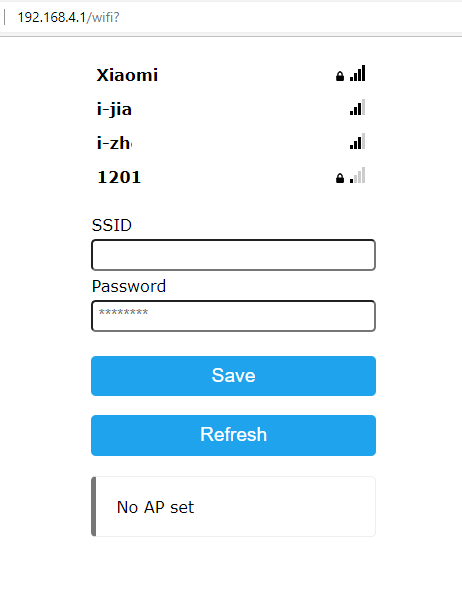

Plug WiFiGPS into USB power socket,if this is the your first time running the WiFiGPS, you need to do some configuration.

You can use a device that supports WIFI connection, like your computer, your laptop ,android cellphone etc.,Then scan for WIFI networks and you should see WIFIGPS-APxxxxx listed.

Connect to this WIFIGPS-APxxxxx WIFI hotspot, then using your web browser go to 192.168.4.1 and you should get the WifiGPSManger main page.(!!!If can not connect to 192.168.4.1,Would please check if you have set VPN or PROXY etc. in your web browser,if so,remove or turn those stuffs off!!!)

For the first time setup,recommend you enter the [Setup] part first,when click the [Setup] button,will list WIFIGPS NTP part parameters for you to set.

The [NTP SERVER NAME] part,you can set or select your own NTP server or select via the list(Please delete the server name first then click the right arrow,will show all predefined servers in the lists,recommend using pool.ntp.org).

Select your [Time Zone] via the second list. The first 7 lists are currently with auto Daylight support (in testing) shown blow.

AustraliaEst-Sydney(GMT+10:Daylight);

CentralEurope-Paris(GMT+01:Daylight);

UK-London,Belfast(GMT+00:Daylight);

US Eastern-NewYork(GMT-05:Daylight)";

US Central-Chicago(GMT-06:Daylight)";

US Mountain-Denver(GMT-07:Daylight)";

US Pacific-LA(GMT-08:Daylight)";

In the [User Define Time Offset(ms)] part,you can set time offset in like +500 for current time+0.5sec,or like -500 for current time -0.5sec to set the time offset you want.If no need this function,set it to 0.

The last [User Define Update interval(sec)] means how many time interval will WIFIGPS sync time via NTP server,like if set to 3600, the WIFIGPS will sync time online via every 1 hour.

(!!!Recommend set in no less than 60 sec. In some of version,if set to 0,the WIFIGPS will enter power save mode,in this mode,the WIFIGPS will do loop,like try to sync time online,then output time data for ~20 sec,then back to sleep for ~30 min,then wake up again!!!).

The [Show WIFI Advanced Options] if be selected,you can set like "Static IP address"... in [Configure WIFI] part.

When all set,click the [SAVE] button blow.

Then back to main page,enter [Configure WiFi] part,enter your WiFi SSID and Password in it,then click [SAVE] button blow.

usually after finished setting the WiFi SSID and Password,the WiFiGPS will reboot,if not,please re-plug the USB power to force it to reboot.

If all setting is correct,the WiFiGPS will try to connect to your WiFi hotspot then sync via online NTP server to get the current time,then output the time data via USB D+ pin in 5V 9600Bps UART output.

Sample Output Format:

$GPRMC,000000.000,N,0000.0000,N,00000.0000,E,0.0,0.0,000000,0.0,E,S*18

$GPRMC,000000.000,A,0000.0000,N,00000.0000,E,0.0,0.0,000000,0.0,E,S*XX

Output speed in 0.5sec per one $GPRMC string.

For the STD. version of WiFiGPS,it contains an led on PCB,when in configure mode or can not connect online or can not get NTP time data,the LED will be turned ON;

When everything is fine,it can SYNC time online and output time data,the LED will be turned OFF.

If you are using OLED version of WiFiGPS,more info will be displayed on the OLED screen on PCB.(If in Power Save mode,the OLED brightness will be turned OFF or in the lowest brightness for saving power).

Reconfigure or reset setting

If you have set the configuration already and you want to reset it,it may have a button on PCB for some version.When the WiFiGPS works in normal working mode(LED OFF,Time Data output in normal) then keep this button be clicked for about 4 sec,will reset all the configuration data.

If it contains no button or you do not wanna click the button,you can turn off your WiFi or move WiFiGPS to a far location where it can not receive the pre-defined WiFi signal,then plug the WiFiGPS in the USB power,wait for a while...,when WiFiGPS can not find pre-defined WiFi hotspot,it will enter the setup mode by itself.

Fri

22

Oct

2021

USB-WIFIGPS Std. Version-Sync time with NTP server via WIFI

Mon

23

Aug

2021

5V USB-ARDUINO NIXIE 3-Tube Thermometer+Humidity

In editing

Feature(For reference only):

1.Silicon based Temperature+Humidity sensor outside PCB via I2C(via 4pin socket on PCB, can ext out <20cm by urself if u want), high accurate, auto switch displaying the temperature and

humidity info on NIXIE tube;The first IN-14 left DOT will be light up if digits over 99 or less than 0;

2.5V USB powered and fully assembled PCB with acrylic enclosure and pluggable female pins on PCB,users only need to plug NIXIE tubes on it by hand;

3.Module based structure via socket,HV module can be replaced by hand, easy to replace it;

4.RGB LED under the NIXIE tube,u can switch the LED color by clicking the switch on PCB,item supports a few pre defined pure colors and rainbow color loop function;

5.ARDUINO UNO (ATMega328) fully open source pure C source code;

6.New NIXIE driver circuit, nixies display in high brightness;

Wed

26

May

2021

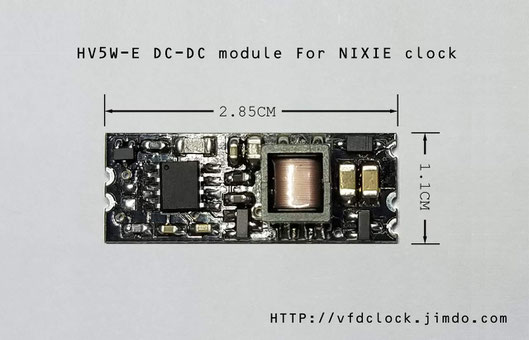

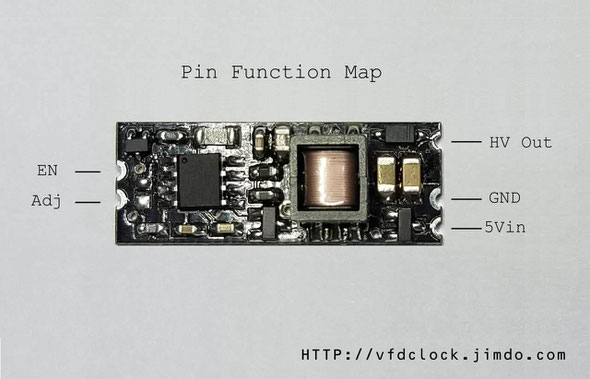

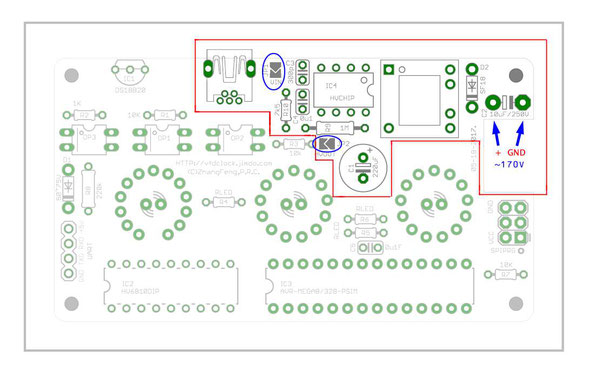

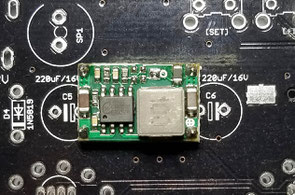

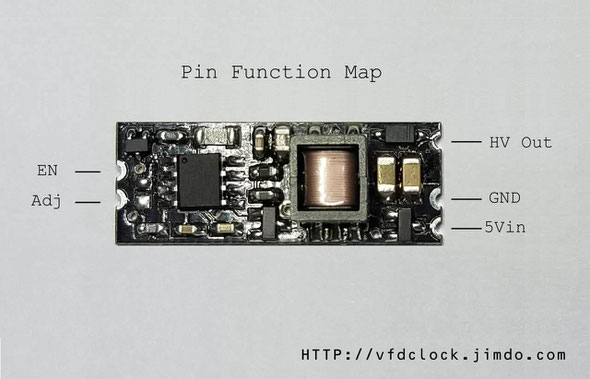

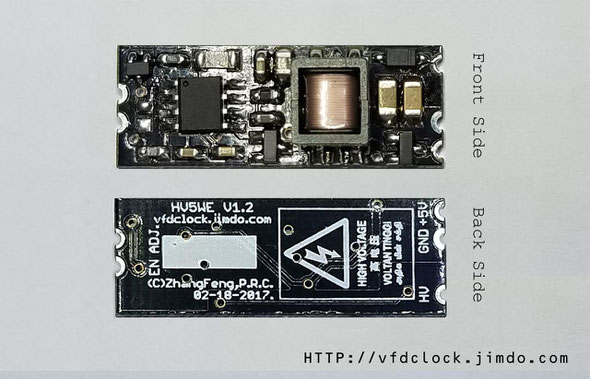

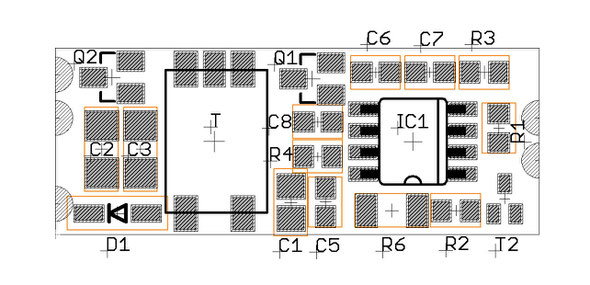

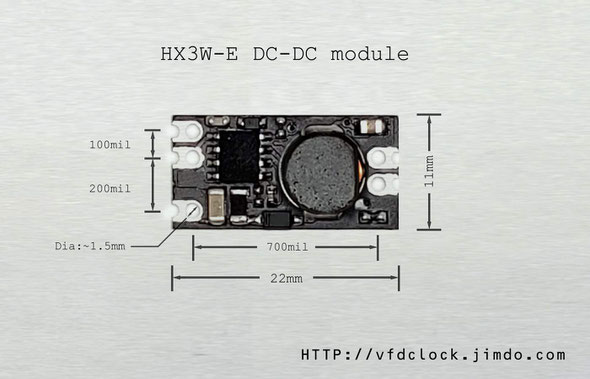

5V Ready-[HX3WE] High Voltage for Driving NIXIE tubes etc.

This is a small size module ,can light up 3~4 pcs if IN-14(or IN-12) nixie tubes with 15k

resistor in serial,or 2pcs in-18 big nixie tubes with 7k5 resisotor in serial.

We use this module for driving out 3-tube IN-14 NIXIE Thermometer,4-tube IN-14 NIXIE Thermomete,4tube DIY IN-12 NIXIE clock,all work fine.

1.In SMD type,only one side of the PCB contains equipments,very thin.Half holes on left&right

side for soldering on PCB as a PSU module on board,also contains Full holes for adding male/Female pins as plug-in module.

2.Please note that the EN pin in this SMD module is not an optional pin,please connect it with a MCU GPIO or connect it to +3V3/+5V to turn the Module

power on(If can add a pull-up resistor (like 10k) to +3V3/+5V will be great);

3.With optional ADJ pin,can adjust the HV output with adding an extra resisotr,HV output adj. range in [~80V~~170V] range.if driving NIXIE tubes only,can connect ADJ pin to GND,the module will

output ~170V;

DANGER! Lethal Potentials

Present

THIS MODULE CONTAINS DANGEROUS, HIGH VOLTAGE

POTENTIALS. USE CAUTION.

DO NOT TOUCH ANY PART OF THE MODULE WHEN IT IS WORKING.

Tips:

1. Standard 0.1"(2.54mm) pins, easy to be used, can use bread board or DuPont-Wires etc.

2. Please control the input current <=400mA for the low heat working state;

3. Module contains over current protection+soft boot-up. When over heat, the module will turn off, you need to re-power on to reset the module;

4. We recommend working under 5V only,no over 6V.

5. More stable HV output, even for the heavy loader, the max output voltage only get a little bit drop;

6. If one module's power is not suited for your app,use two or more modules for driving the separated NIXIE tube(s) group,etc.;

7. Do not connect the modules' outputs in "Parallel Connection"!!!

Specifications(For reference only):

Module Size : 22mm(L)*11mm(W)*~6.4mm(H);

Module Pins : Half holes in 0.1"(2.54mm) std. gaps;

PCB Color : Black;

Freq: ~85kHz;

Pin Functions

|

ID |

Name |

Description |

|

0 |

Vcc/+5V |

Input supply voltage, 4.5V to 12V.(Recommend 5V only, no over 6V) |

|

1 |

GND |

Ground |

|

|

|

|

|

3 |

HV |

High voltage output. +170V(+-5%) |

|

4 |

EN |

Enable pin for turning the module ON/OFF |

|

6 |

ADJ |

add extra resistor to Ground can adjust the HV output from [~80V~~170V] Range,(Optional,if no use,connect to GND,module will output ~170V) |

*EN pin can be controlled by MCU GPIO[*3V3 or 5V MCUs are all fine]) directly,no need to add resistor in serial.

For 24*7 continually working condition, we recommend you control the input current less than 400mA when under 5V in, it keeps this module working under the low heat condition.

Typical Usage:

For driving NIXIE Tubes;

Tue

25

May

2021

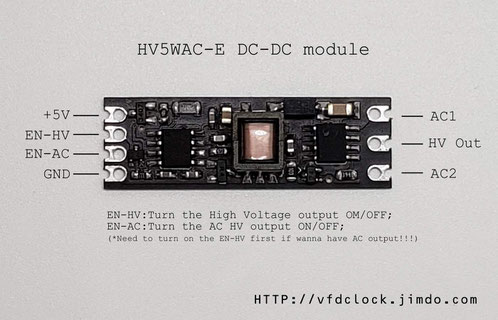

5V Ready-HV5WAC-E New HV NIXIE module with DC+AC output

NEW-[HV5WAC-E]-Smaller HV5W with DC+AC output HIGH VOLTAGE

NIXIE POWER SUPPLY MODULE PSU-NIXIE TUBE ERA

Same Like Normal HV5W module but with an extra HV DC2AC convert circuit

inside it.Now can output not only HVDC but HVAC for driving the neon lamps(To light two pins up inside the neon lamps).

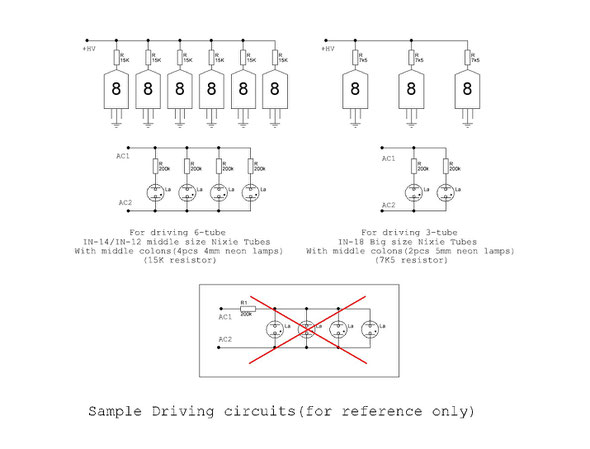

We recomment using this module for driving 6tube IN-14(or in12 etc.) +4pcs neon lamps as middle colons or Driving 3tube IN-18 nixie tubes+2pcs neon lamps (thus for 6tube IN-18 nixie clock ,u need two of this module),the +HV DC output is for driving Nixie tubes and AC1+AC2 HV output is for driving Neon lamps as middle colon,thus two pins inside neon lamps all can be light up because of we are using AC HV to drive it.

1.In SMD type,only one side of the PCB contains equipments,very thin.Half holes for soldering on PCB

as a PSU module on board,also contains Full Round Holes for users to add Male/Female Pins as a plug-in module.

2.Please note that the EN-HV and EN-AC pin in this SMD module is not a optional pin,please connect it with a MCU GPIO to control it or directly connect to +3V3/+5V to

turn the Module power on;

DANGER! Lethal Potentials

Present

THIS MODULE CONTAINS DANGEROUS, HIGH VOLTAGE

POTENTIALS. USE CAUTION.

DO NOT TOUCH ANY PART OF THE MODULE WHEN IT IS WORKING.

Tips:

1. Standard 0.1"(2.54mm) pins and SMD half holes, easy to be used, can use bread board or DuPont-Wires etc.

2. Please control the input current <=800mA for the low heat working state;

3. Module contains over current protection+soft boot-up. When over heat, the module will turn off, you need to re-power on to reset the module;

4.We recommend working under 5V only,no over 6V.

5. More stable HV output, even for the heavy loader, the max output voltage only get a little bit drop;

6. If one module's power is not suited for your app,use two or more modules for driving the separated NIXIE tube(s) group,etc.;

7. Do not connect the modules' outputs in "Parallel Connection"!!!Do not Connect The +HV putput pins with AC1/AC2 pins, do not short HV And

AC1/AC2 pins!!!

Description:

HV5WAC-E is a newly designed high voltage module, it works under 5V USB power, with ~170V

DC output via +HV pin and HV AC output via AC1+AC2 pins,(especially designed for driving the NIXIE tubes. The max power

output is enough for lighting up 8PCS IN-14 NIXIE tubes(Or 4PCS IN-18 with

all segment "8" been light up) + 4PCS NE-2 neon bulbs. Low EMI and with No audible noise.

It contains an ENABLE pin to turn the module on/off, and

can be controlled by an regular logic signal, like a MCU's GPIO PIN(3V3 or 5V MCUs are all fine).

Pictures/Video(s) of the module

(For reference only):

Specifications(For reference only):

Module Size : 37mm(L)*11mm(W)*~6.4mm(H);

Module Pins : Half holes in 0.1"(2.54mm) std. gaps, output part in 0.15#;

PCB Color

: Black;

Freq: ~85kHz;

Pin Functions

|

ID |

Name |

Description |

|

0 |

Vcc/+5V |

Input supply voltage, 4.5V to 12V.(Recommend 5V only, no over 6V) |

|

1 |

EN-HV |

Enable pin for turning the +HV output ON/OFF |

|

2 |

EN-AC |

Enable pin for turing the AC1+AC2 output ON/OFF(The EN-HV pinmust be on first) |

|

3 |

GND |

Ground |

|

4,6 |

AC1+AC2 |

High voltage AC output ;~170V (+-10%) |

|

5 |

HV |

High voltage DC output. +170V(+-5%) |

*EN pin can be controlled by MCU GPIO[*3V3 or 5V MCUs are all fine]) directly,no need to add resistor in serial.

For 24*7 continually working condition, we recommend you control the input current less than 800mA when under 5V in, it keeps this module working under the low heat condition.

And this module is also suite for driving 6 tubes IN-18 clock, you just need to use two modules for driving it. Each module can drive 3PCS IN-18 tubes + 2PCS NE-2 neon bulbs (as dots) with no problem.

Typical Usage:

For driving NIXIE Tubes;

When under heavy loader,eg:output over

18mA,under 24*7 condition,the Max temperature of the transformer is about: Room temperature+20℃;Other parts get almost no heat.

Sun

07

Feb

2021

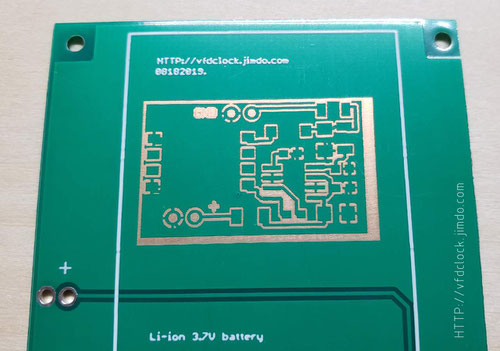

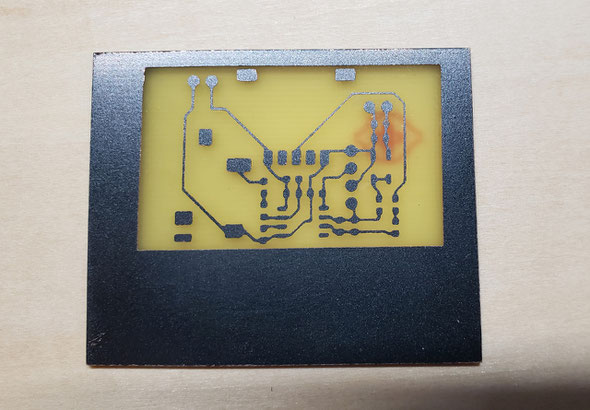

How to make a fast testing PCB by using a CO2 laser cut

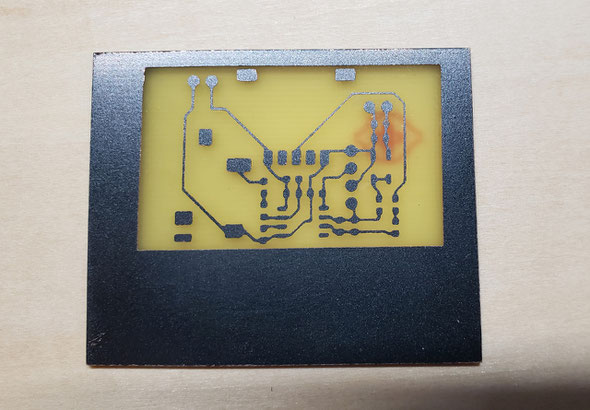

In this article we are going to teach you how to create a fast tesing PCB if u have a CO2 laser cut.

For small size testing PCB,it costs us less than 30 mins to get a working PCB.

First prepare a regulaer PCB made by factory with a clean area that contains flat copper under the Green UV painting as u can see in the pic.

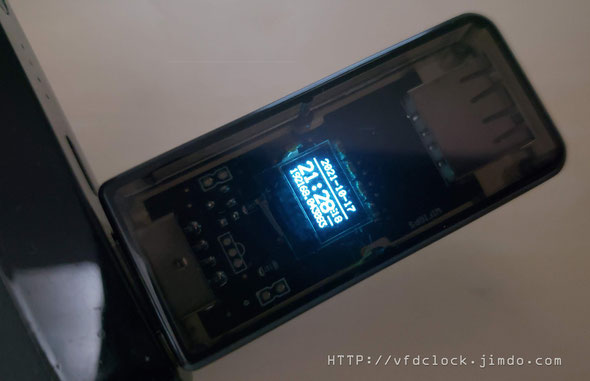

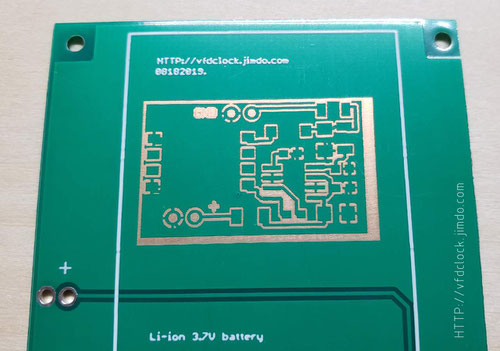

In this sample,we use an old Li-ion battery PCB which we designed for installing battery for our IN-18 SD clock PRO. It contains enough space to create our testing PCB.

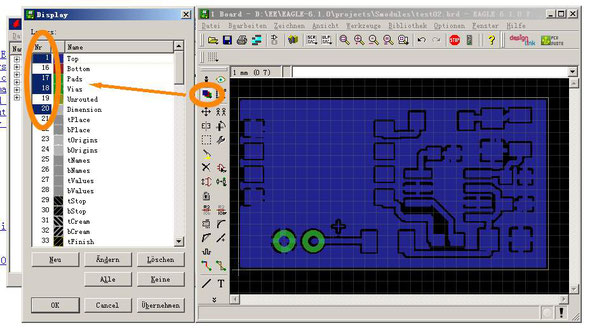

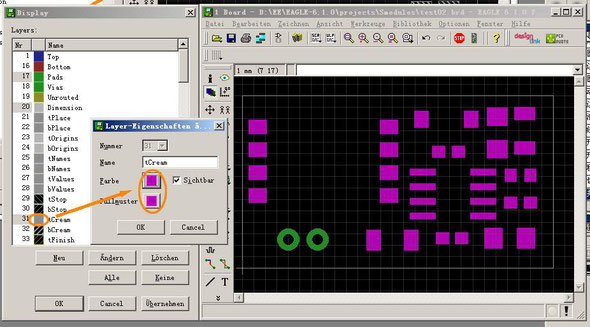

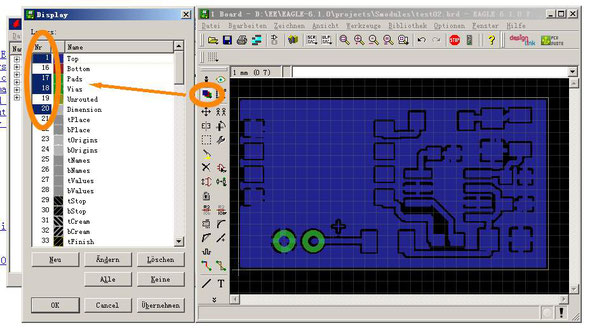

We are using EAGLE PCB V6 software, now export the first mask picture.

As u can see in the TOP pic,first,display only [TOP]+[PADS]+[Vias]+[Dimention] layers only.

Then export the first mask pic to a BMP file,by using export -> image function as u can see in the picture.

We use 1200dpi high resolution and output [Monochrome] BMP file.

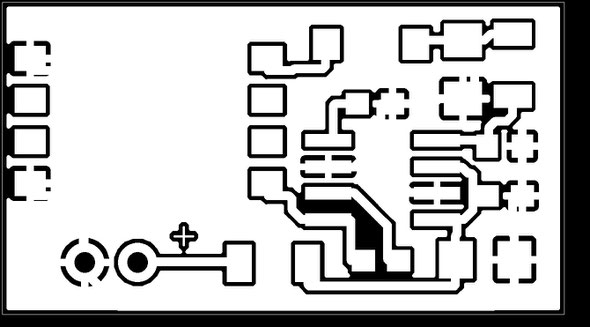

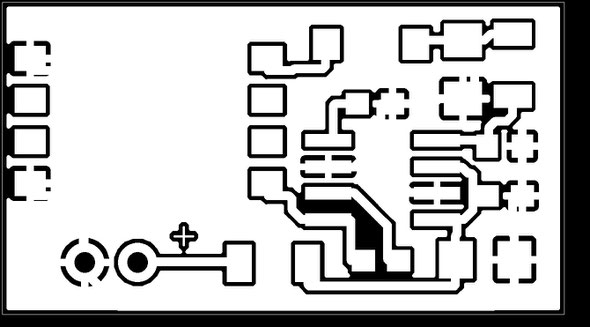

Here is the output a.bmp mask file. Then import the BMP file to ur Laser Cut Software to burn it to the PCB.

We are using a 40W 3040 Co2 laser cut machine,only need to set 7%~10% output laser power, this power is enough to burn the green UV painting layer from the PCB surface.

After washing the PCB surface,we can goto the etching PCB part.

In eaching part,u can use:

1. Use traditonal FeCl3(direty);

2. Use mixture of hydrogen peroxide (H2O2) and hydrochloric acid (HCl) in about water+H2O2+HCl=1:1:1 ratio; (Fast,but damgerous);

3. Use Sodium persulfate (Na2S2O8);(the key is the temperature and pumping air bulb in);

After the PCB is being etched,need to remove the green UV painting on its surface.if u do not need any of the green painting on it,u can use sandpaper to remove all of it. But we can do it in more elegant way as u can see later.

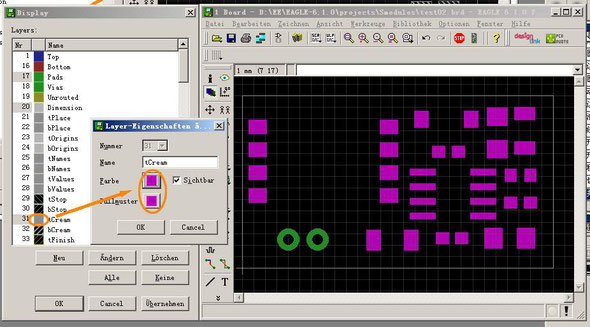

Let us output another mask that contains the [Pads]+[Dimention]+[tCream] layers.

The problem in this step is the cream parts are not displayed in solid color,we need to change the layer setting to make it displays in solid way.

Double click the bar near "31[ ]tCream" in the layers list,change it to solid color.As u can see in the picture,no need to care about the color because we will output the mask into mono in the next step.

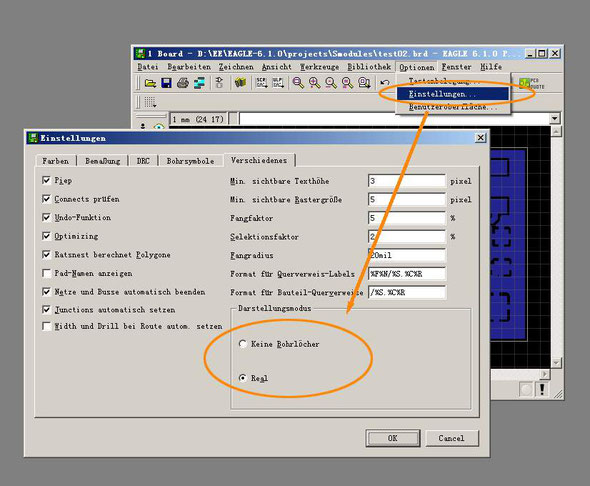

Do the same step to export it to a BMP file in 1200dpi, monochrome as u have done before.

Here is the output b.bmp mask file. Then import the BMP file to ur Laser Cut Software to burn it to the PCB.

Then all the parts that need to be solder will be appeared without green painting.

TIPS:

If need to drill holes,we recommend u do it before etching.

If need to get more HQ result,do Co2 laser focus calibration first;

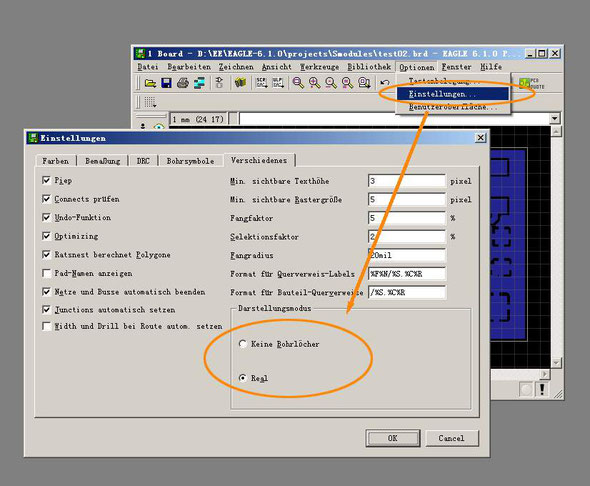

If u want to output the PADs in Solid with no middle hole,please change the setting shows in blow picture.

Coating a layer of black painting on regular cu PCB surface also works fine.Pics shown blow.

Thu

21

Jan

2021

5V ready OLED-1602 module for ARDUINO via IIC

You can find the password of PDF inside the item parcel.

OLED1602 Module for

Arduino /AVR/PIC/STM/ARM/PI 5V ready

Specifications(For reference only):

PCB Size: 82mm*22mm;

PCB color: Green/Black;

OLED Panel Size: 68.5mm*17.5mm;

Active Area: 2.26";

Panel Color: Blue;

Weight: ~12g;

Supply Voltage: 3V3~5V;

1). 5V Supply + 5V IO;

2). 3V3 Supply + 3V3 IO;

3). 5V Supply + 3V3 IO; (!!!No recommend! On your own risk!!! May work with some STM32 MCU Pins that survive under 5V IO,recommend add 1K resistors in serial with IIC pins);

Max Current: ~100mA;

Port: IIC (4k7 IIC pull-up resistors on PCB.);

Pins:

VDD +3V3~+5V;

SDA: IIC data pin;

SCK: IIC clk pin;

GND: Ground;

--------Optional pins(May not exist,depends on PCB version!!!)-----

HVEN: turn HV on/off(Optional);

/RESET: reset pin(Optional);

The module works with any 5V DC MCU,especially designed for ARDUINO!

Features:

1). 5V Ready,easy to be used.Can connect to your ARDUINO UNO board with only 2 signal wires;

2). High Brightness,no heat;

3). All SMT components,very thin PCB,easy to be drived;

4). Contains over-current protection and reverse connection protection circuits;

5). Open source ARDUINO UNO source code,pure C code,easy to be used and ported;

For video(s):

HTTPS://youtu.be/i9q9lQ41UB0

For more information:

HTTP://vfdclock.jimdo.com

The source code is for ARDUINO UNO,running in ARDUINO V1.04.

Please use Acrobat Reader from ADOBE to open this PDF file,then you can find the source code in the PDF attachment.

Sun

22

Nov

2020

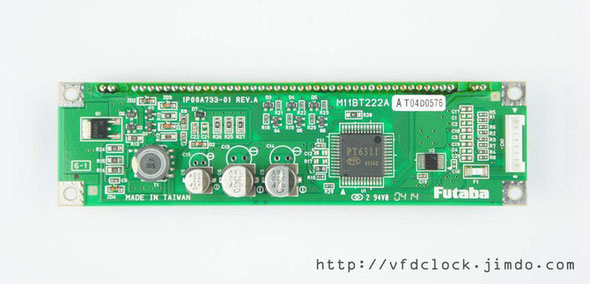

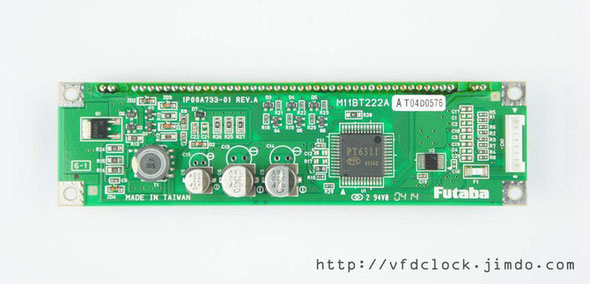

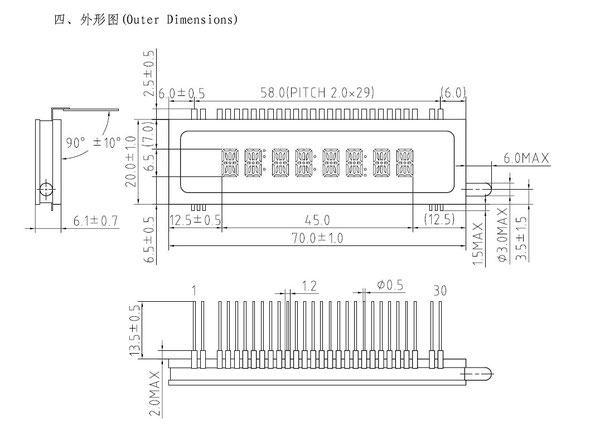

FUTABA M11BT222A VFD(Vacuum Fluorescent Display) Module

Outside link:

Have found C51 source code in:

https://blog.csdn.net/farmanlinuxer/article/details/78993335

Specification:

Module Size:150mm(L)*40mm(W)*20mm(T);

Socket Pitch:2.0mm*8pins;

App: Set-Top Box(STB)/HTPC/Video Player&Recorder;

Color:Green+Red;

Operating Condition:

Power

supply:5V DC;

Current: ~500mA;(5V,light up all the segments together.)

Pins definition:

1. VCC (+5V)

2. GND

3. NC(no connection)

4. EN(High:HV+Filament On; Low:Shut-down)

5. DIN

6. GND

7. /SCL (invert)

8. /STB (Invert)

Driver Chip:PT6311

Thu

14

Nov

2019

5V Ready-VFD Matrix Module for Arduino/STM32 etc.

Caution:

1.High Voltage(~100V) on board,do not touche any part of PCB with power on;

2.May have tiny sound when displaying that is from filament which is caused by internal driving IC inside PANEL in scanning freq; You can install the module inside an enclosure to reduce the sound;

Would please use Adobe Acrobat Reader to open this PDF file,and you can find source code zip file in the attachment part of PDF file.

For video: https://youtu.be/YXwZPGMiKqk

Panel Size: 150mm*48mm;

Panel Color: Green;

Supply: 5V DC;

Max Current: ~800~1000mA;

Module Size:~ 166mm(L)*62mm(W)*--mm(H);

PCB Size: ~166mm*62mm;

PCB Color: Black/Green;

Weight: ~--g;

Features:

1).5V Ready, easy to be used. Can connect to your ARDUINO UNO board with only 3 signal wires;

2).High efficiency power circuit, High Brightness;

3).All SMT components, very thin PCB, easy to be driven;

4).Logic part support 5V or 3v3 signal;

5).Contains over-current protection, and reverse connection protection circuits;

6).Open source ARDUINO NUO source code, pure C code, easy to be used, also provide a simple flip clock source code for ARDUINO UNO.

7).Simple 3-wire SPI interface, with EN pin, support shutdown the High Voltage and Filament Supply completely.

Interface:

3-wire SPI: DIN/CLK/LATCH(CS)

---------------------------

+5V (main power.)

GND

DIN

CLK

LATCH(mark:CS on PCB)

-------Other pins----------

+3V3 out 100mA (max) (optional)

INT-SYNC out (optional)

EN High voltage & filament supply enable(optional)

Logic part is 5V and 3v3 compatible.

Arduino fake flip clock source code in pure c;

For video:

https://youtu.be/YXwZPGMiKqk

Thu

14

Nov

2019

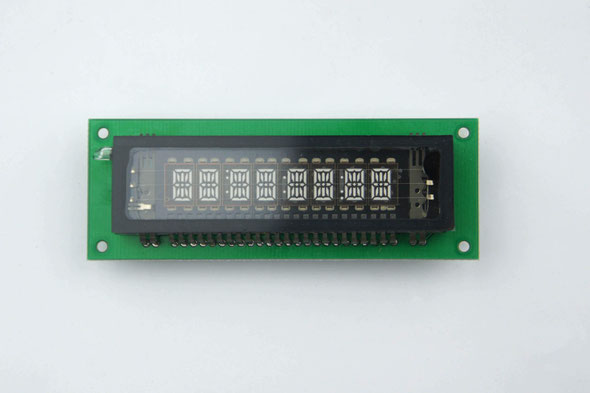

5V Ready-HLD026 VFD module for Arduino

Arduino Source code for ARDUINO UNO.

Compiled under ARDUINO V1.0.4 in pure C code.

Please use ACROBAT reader from Adobe to open the PDF file and find Source code files in attachments part of PDF.

You can find the password of PDF inside the parcel.

Specifications(For reference only)

VIN:5VDC/~150mA

Panel size: 106mm*25mm

PCB size: 116mm*32mm

Color: Green

Display:SEG * 10

Driver Chip: PT6312

Features:

1).5V Ready, easy to be used. Can connect to your ARDUINO UNO board with only 3 signal wires;;

2).High efficiency power circuit, no transformer, no heat, Low HV, very safe, High Brightness;

3).All SMT components, very thin PCB, easy to be drivered;

4).Contains over-current protection, and reverse

connection protection circuits;

5).Open source code for ARDUINO NUO, pure C code.

6).Simple 3-wire SPI interface, with EN pin, support shutdown the High Voltage and Filament Supply completely.

Interface:

3-wire SPI:

DIN

CLK

LATCH(CS)

+5V

GND

EN - HV supply enable(optional)

For Video:

https://youtu.be/0dTg2ngvf1c

For video(s):

Thu

31

Oct

2019

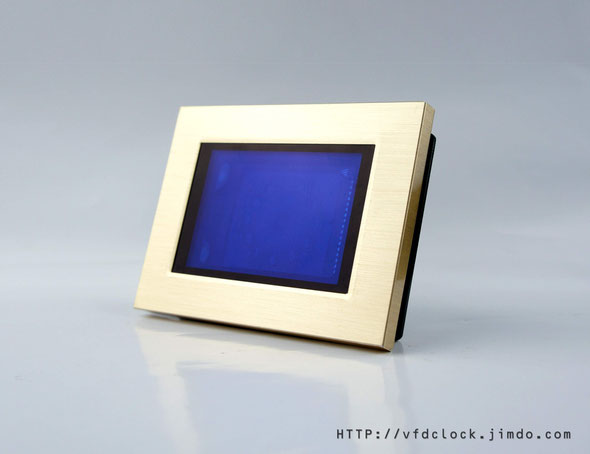

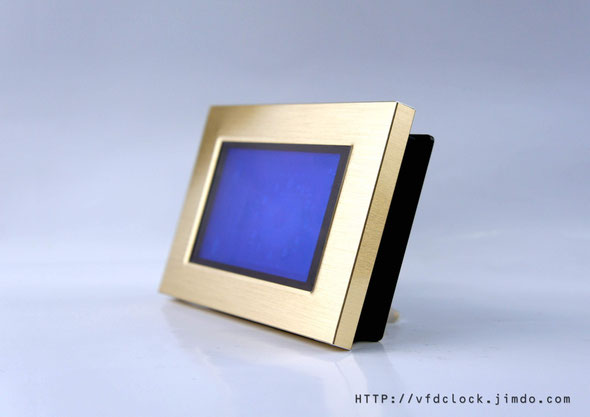

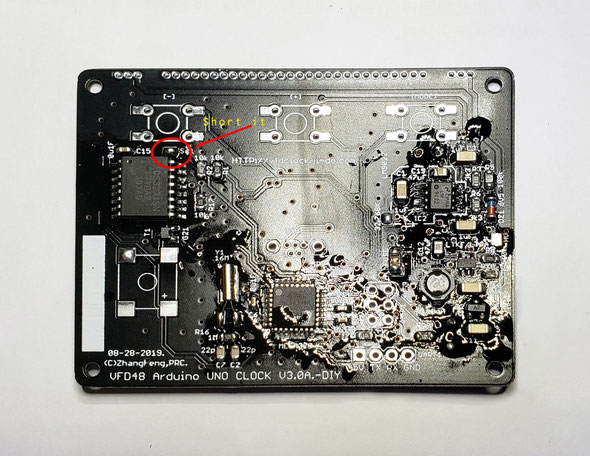

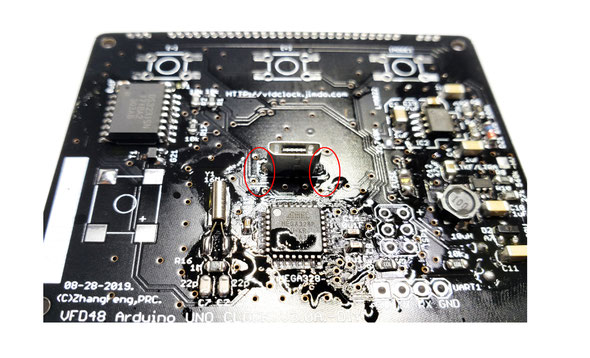

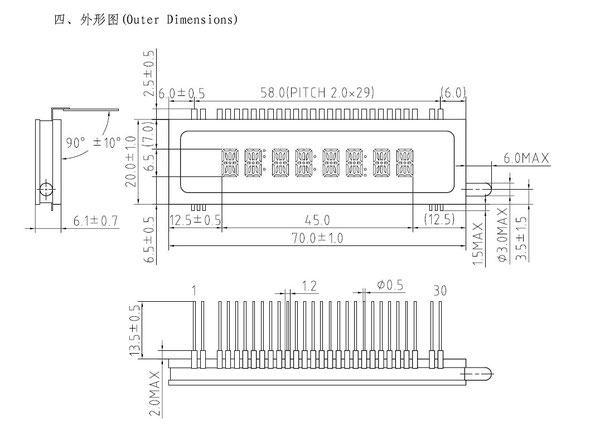

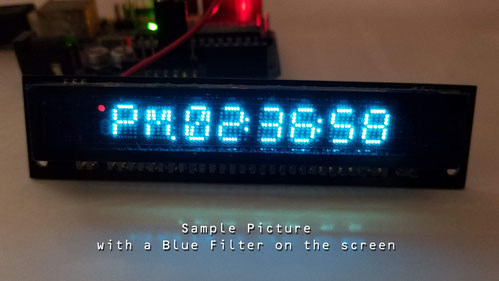

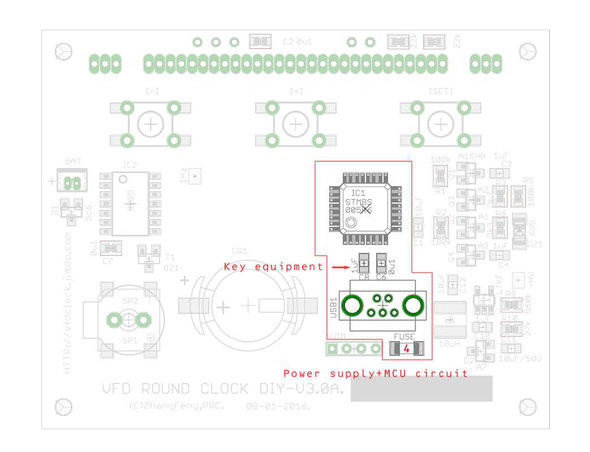

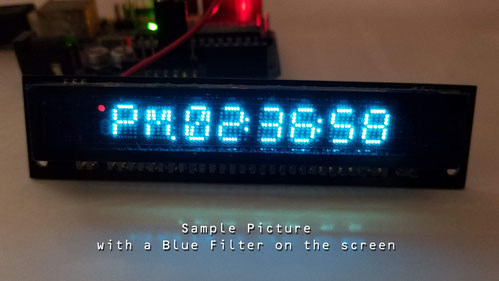

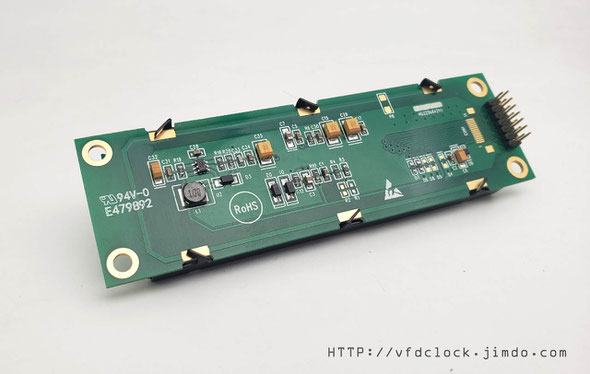

Arduino Open Source-USB-VFD48 MINI DIY Clock Assembly Instructions

VFD48 MINI

Pure C source code for Arduino V1.0.4

Please use ACROBAT READER to open it or you may not be able to get the attach file inside it.

Please select ARDUINO UNO board in arduino compiler.

if can not open pdf attached file,would please send us a email,we will send u src directly,u can gind our email address inside pdf file.

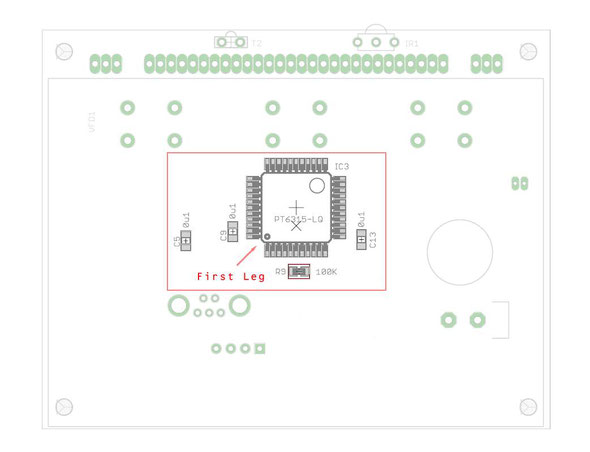

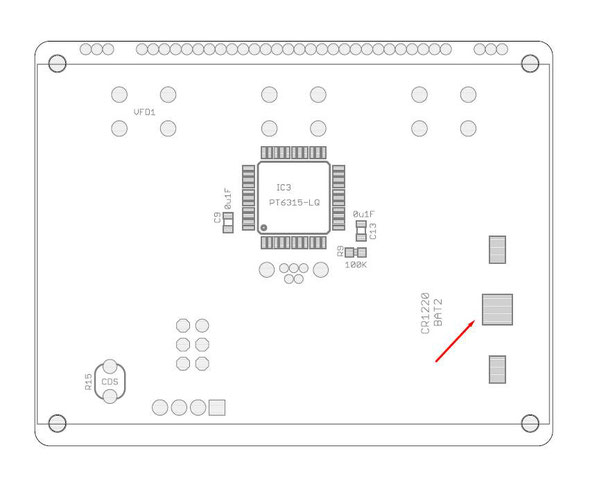

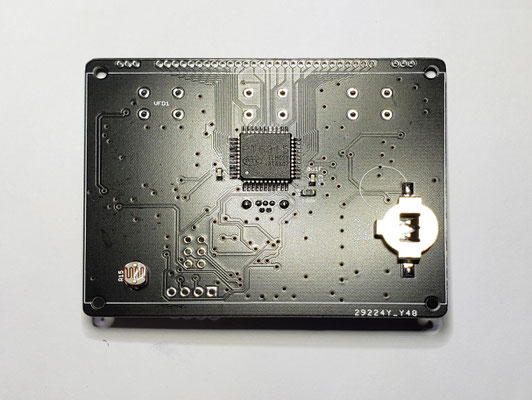

First,solder the front side of PCB, It contains few equipments on this side,please double check the direction of the PT6315 Chip before soldering it on PCB.

Recommend glue the chip on PCB by using tape before soldering.

Remember tin the middle pad of the CR1220 battery socket,and check the direction of the battery socket.

Plug the CDS sensor near the PCB or it will effect the VFD48 panel installtion.

Most of the equipment on the back side of the PCB,please solder it carefully.

1)Solder the MCU part first and the crystal part,please double check the direction of MCU and solder the crystal fast,other small resistors and caps are easy.

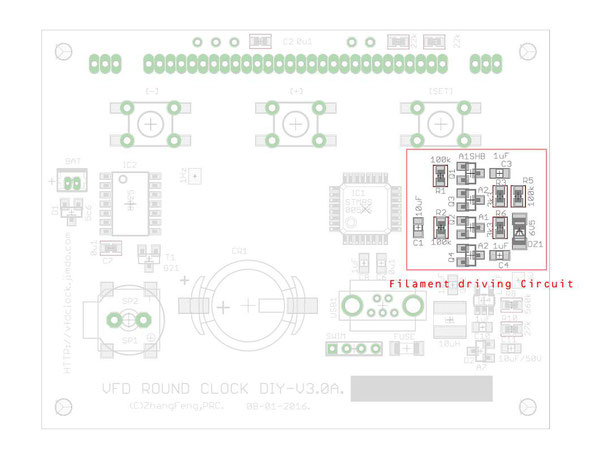

2)solder the -HV part on the right bottom side and filament driver part on the top bottom side,same as the prv. step,please double check the IC direction and solder fast.

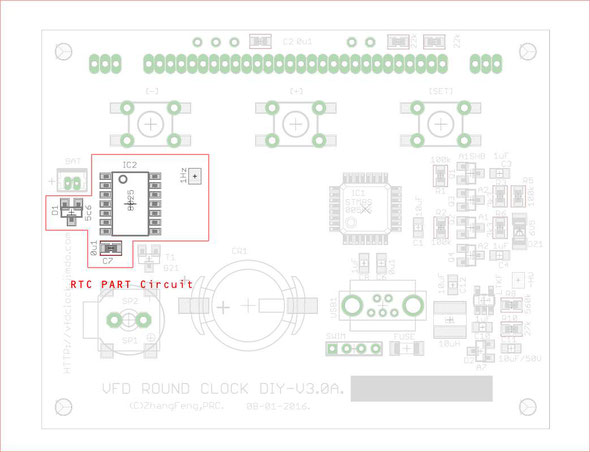

3)Solder the RTC part on the top-right side of the PCB,in this part,remember to short the small pad on the top of the RTC chip, this pad is for the 5V supply of the RTC chip, if you left it open, the RTC chip will not work.

4) Solder the USB socket on PCB,please also remember to solder the left and right holes part of the usb soket as shown on the pic.

Give it a double check of all the components, if all fine ,we can do a test to see if the PCB in working.

We plug the VFD48 panel on the PCB,press it to make all its legs touchs the holes, then plug the USB power on,if all fine,the VFD48 panel will in running. It will be light up,and the time will ticking.

!!!Do not solder the VFD48 panel on if the circuit did not work!!!

If all fine,you can wash the PCB to make it clean.

Then we will solder the rest components on the PCB.The keys and buzzer can not be washed,thus we nned to solder these things in the last step.

5) cut the keys' legs short then plug it on the PCB,you can solder it on the top or on the bottom side of the PCB.

6)Solder the buzzer on the PCB,please double check it's direction,check the [+] pad.

7) Plug the VFD48 panel on the PCB,power on ,recheck all things again,if all fine,you can solder the VFD48 panel on.

Tips:you can older the left one leg first then adjust the installtuon height of the panel,then solder the one leg of the left side. if all fine,then you can sut all the legs short,solder all the rest legs on the PCB.

After assemble the PCB,we recommend you do at least 48Hours heat testing,if all fine,then we can install it in the aluminum enclosure.

Aluminum Enclosure Assembly Instructions

First install the 5mm Copper column as shown in the pic.

Then glue the blue filter on the VFD48 panel by using double-side tape.Recommend glue on the top and bottom side.

The blue filter contains protective film on both side,remove it before you use it.

Now install the PCB into the aluminum enclosure. Then glue the front panel on by using the double-side tape on its surface.

Done!

Tue

29

Oct

2019

GTF07 Dot char VFD display module with ARDUINO C source code

Arduino Source code for ARDUINO UNO.

Compiled under ARDUINO V1.0.4 in pure C code.

Please use ACROBAT reader from Adobe to open the PDF file and find Source code files in attachments part of PDF.

Specifications(For reference only)

VIN:5VDC/~150mA

Panel size: 85mm*16mm

PCB size: 100mm*20mm

Color: Green

Display:[5*7 dot] 7chars.

Driver Chip: COG

Features:

1).5V Ready, easy to be used. Can connect to your ARDUINO UNO board with only 3 signal wires;(Logic part supports 5V or

3V3 logic with no problem);

2).High efficiency power circuit, no transformer, no heat, Low HV, very safe, High Brightness;

3).All SMT components, very thin PCB, easy to be drivered;

4).Contains over-current protection, and reverse connection

protection circuits;

5).Open source code for ARDUINO NUO, pure C code.

6).Simple 3-wire SPI interface, with EN pin, support shutdown the High Voltage and Filament Supply completely.

Interface:

3-wire SPI:

DIN

CLK

LATCH(CS)

+5V

GND

EN - HV supply enable(optional)

For video(s):

Tue

10

Sep

2019

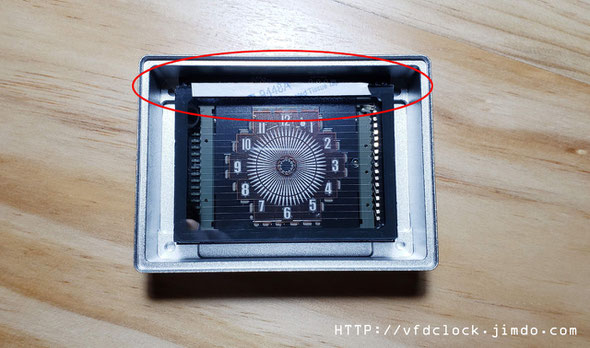

VFD48 Aluminum enclosure assembly instructions

You can find this enclosure from our ebay store.

Please check the links on the right-top of this webpage to visit.

Specifications(For reference only):

Enclosure Size:90mm(L)*66mm(W)*24mm(H)

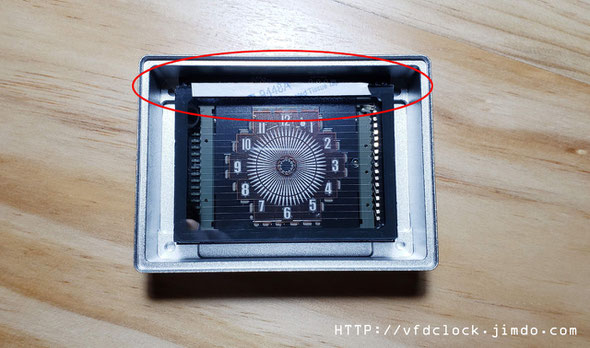

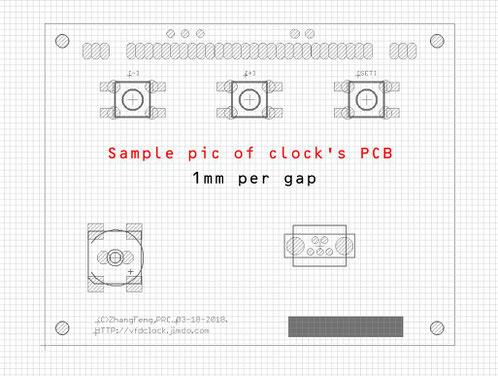

Before you start to assemble the enclosure,please double check the 1mm gap pic of PCb on the pic to see if your VFD48 clock FITs,99% of our vfd48 clock PCB are all fit with no problem,the buzzer beep-hole may face to top-side or left-side,all work.

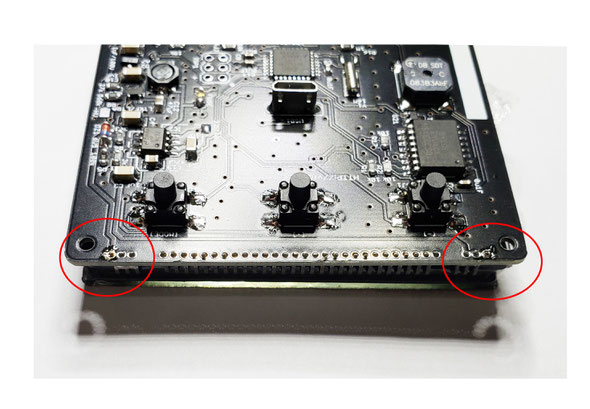

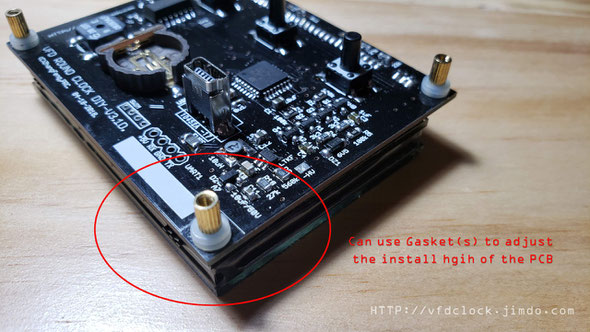

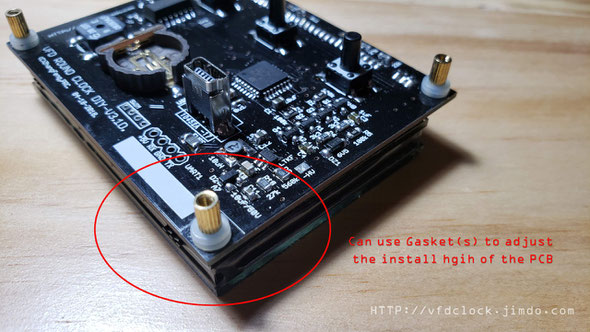

First install the 5mm Copper column with 2pcs plastic gaskets as shown on the pic, Do not scrow too tight,may need adjust the distance a little bit when plug in the enclosure.

!!! Total high of the bottom side of the PCB is :

5mm(Copper column)+1mm(gasket)+1mm(gasket)=7mm;

Because of we do not know how high you have installed the VFD48 clock panel,you can install only 1pcs or none of the gaskets to make sure that when the vfd48 clock PCB be installed inside the enclosure, you can still install the acrylic panel on with no problem,and all 3pcs of buttons can be pressed on the back side.

Plug the VFD48 clock PCB in the enclosure,make sure all 4pcs of Copper column be plugged inside the 4 holes. If all fine,you can add a little bit of epoxy in the 4 holes to glue the Copper column inside the enclosure, and then wait untill the epoxy becomes solid.

Then glue a short of paragraph transparent double-side tape on the top edge of the clock panel,as you can see in the picture,we will need to glue the blue filter in next step.

The blue filter contains protective film on both side,remove it before you use it.Then glue the blue filter on the VFD48 panel.

Tips:In some of version,you can also try to glue the blue filter on the middle of the front panel.

Now you can install the front panel. On the back side of the front pancel contains Double-side tap to glue the pancel on the enclosure,and after be installed,you can remove the protective film on the front side.

Tue

20

Aug

2019

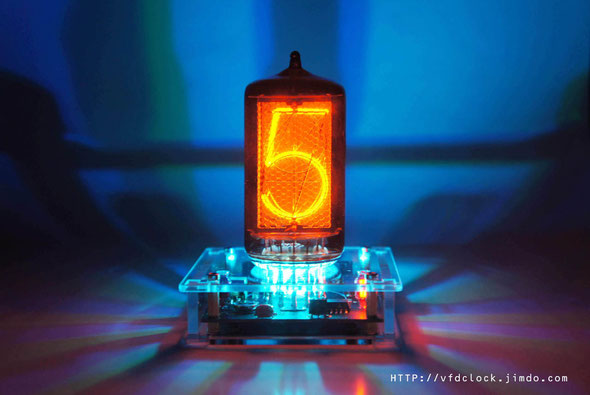

USB Powered IN-18 Single Digit NIXIE Clock Pro

For PDF instructions,check:

USB Powered IN-18 Single Digit NIXIE Clock with Aluminum Enclosure V1.0.

IN-18 Single Digit NIXIE Clock with aluminum enclosure

Brand new,I designed and made it by myself.

Notice:

In order to drive the NIXIE tube, some

internal equipments are under the High Voltage(up to 180V DC),please do not use this clock outside or in any wet conditions,please do not touch any part inside the clock when power supply is

turned on.Always keep it away from kids.

Specifications(For reference only):

Tube Name: IN-18 (Made in the U.S.S.R.);

Tube Size:30mm(dia);

Tube Height:68mm(no including the legs and the glass

nipple);

Digit Height:40mm;

Digit Width:22mm;

Clock Supply: 5V DC via MINI-USB;

Working Current: ~250mA(Without Li-battery)/~450mA(With Li battery in charging);

Clock Size:60mm(L)*60mm(W)*25mm(H*without NIXIE tube)

PCB Size:54mm*54mm;

PCB Color: Green or Black;

Weight:~128g(weight with the tube installed);

The clock works with any standard USB power supply,use only high-quality adapter!

Features(For reference only):

You can replace the tube by yourself without using any tools.

1). 5V USB powered,easy to be used. Can

connect to your computer's USB plugs directly.

2). Support 12H or 24H display modes, can show "."as“A/P" in 12H time format.Leading zero blanking is programmable.

3). Display date in all format: YY.MM.DD or DD.MM.YY or MM.DD.YY or even MM.YY.DD.

4). Support different Effs:Normal/Fading/Cross Fading/Slow Fading/Loop for displaying time.

5). High accuracy DTCXO (temperature compensated crystal oscillator) inside,+-4.94 seconds(MAX) per month.

6). Simple setting by using 2 buttons only and supports IR remote control(optional).

7). Three alarms with weekends ON/OFF support,can be controlled individually.

8). Three programmable Auto Power ON/OFF mode,can turn ON/OFF NIXIE tubes in any time you want.This function can save tubes life.

9). 8-level adjustable NIXIE tube bright with Auto-brightness feature(its ability to adjust the tube brightness depending on the current environment).

10). Rechargeable Backup Battery or Farad capacitor Or CR1220 battery keeps RTC running during power outages.

11). Tri-colored RGB LED mounted under the NIXIE tube. This LED can display any color with a lot of predefined auto color change effects.

12). Store user settings in non-volatile memory.

13). Beautiful CAD designed ,CNC made aluminum enclosure makes the clock look beautiful. You can assemble/disassemble the case by using only 4 screws on the bottom of the case.The case

also has 4 bumpers as feet on the bottom of the case in order to stop to prevent case's damage.

14). Support temperature sensor(optional).

15). Support wireless GPS time sync receiver(optional).

16). Supoort Li battery function(optional).

For video(s):

For more information visit:

vfdclock.jimdo.com

For Instructions:

Please visit the url in

the bottom side of the pictures to get the PDF instructions,

etc.

more info...

Mon

01

Jul

2019

USB powered-B7971 6-tube NIXIE clock

Instructions:

Tue

11

Jun

2019

USB Powered 6E1P(EM80) 2-tube Magic Eye VU Meter(Stereo Audio Visualizer)-V1.0

6E1p 2-tube vu meter

Tue

11

Jun

2019

USB powered-Z566M Single Digit NIXIE Clock

Z566m Single digit NIXIE clock

-------------------------------------------------------------------------------------------------------

USB Powered Z566M

Single Digit NIXIE Clock with acrylic enclosure. -NO

TUBE

!!!This Item Contains No Z566M

TUBE.All you need to do is buy 1PCS Z566M NIXIE Tube and plug it in the socket by hand.

For review article(For

reference only):

Z566M Single Digit NIXIE Clock with acrylic enclosure

-----------------------------------------------------------------------------------------------------

Product Change Notification in the New Version:

Specifications:

Tube

Name:Z566M; <<<===Prepare the tube by yourself.

Clock Supply: 5V DC via USB;

Working Current: ~350mA;

Clock Size:58mm(L)*54mm(W)*80mm(H)

PCB Size:48mm*44mm;

PCB Color: Black;

Weight:58g(weight with the tube installed);

The clock works with any standard USB power supply,use only high-quality adapter!

Features:

You can replace the tube by yourself without using any tools.

1). 5V USB powered,easy to be used. Can connect to your computer's USB plugs directly.

2). Support 12H or 24H display modes, can show "."as“A/P" in 12H time format.Leading zero blanking is programmable.

3). Display date in all format: YY.MM.DD or DD.MM.YY or MM.DD.YY or even MM.YY.DD.

4). Support different Effs:Normal/Fading/Cross Fading/Slow Fading/Loop for displaying time.

5). High accuracy RTC inside,+-13 seconds(MAX) per month.

6). Simple setting by using 2 buttons only and supports IR remote control(optional).

7). Three alarms with weekends ON/OFF support,can be controlled individually.

8). Three programmable Auto Power ON/OFF mode,can turn ON/OFF NIXIE tubes in any time you want.This function can save tubes life.

9). 8-level adjustable NIXIE tube bright with Auto-brightness feature(its ability to adjust the tube

brightness depending on the current environment).

10). Rechargeable Backup Battery or Farad

capacitor keeps RTC running during power outages.

11). Tri-colored RGB LED mounted under the NIXIE tube. This LED can display any color with a lot of predefined auto color change effects.

12). Store user settings in non-volatile memory.

13). Beautiful CAD designed acrylic case made using a laser cutter makes the clock look beautiful. You can assemble/disassemble the case by using only

4 screws on the bottom of the case.The case also has 4 bumpers as feet on the bottom of the case in order to stop to prevent case's damage.

14). Support temperature sensor(optional).

For Video(s):

https://youtu.be/UuLHPXgxT3I

For Instructions:

Please visit the url in

the bottom side of the pictures to get the PDF instructions,

etc.

For more information and newest instructions,please visit:

Contains:

1. 1PCS fully

assembled clock(with NO Z566M NIXIE tube,all installed in an acrylic case,with USB

cable), ready to go,just plug your IN-18 tube in it,and connect with the USB power.

Power adapter is not included, any USB adapter may suit,or you can connect it to the USB ports in your

computer.

Optional extra:

1.For the IR Remote Control Function(With 1PCS Remote Control ): +5.99 USD;

2.For the Temperature Sensor Function:+5.99USD;

3.For an extra acrylic case with all screws,bumpers,etc. as backup:+5.99USD;

4.For 1PCS Brand 5V/1A USB Power Adapter: +5.99 USD;

Battery is not included!!!(We can't ship the battery in the mail package,so the IR remote control battery(1pcs CR2025) may not be included,you need

to prepare it by yourself.)

Notice:

Please note that we need about 3~5 working days for assembling it after payment is received.

We may will change the Outlook/Circuit/PCB/Components without notification!

Payment methods:

We ONLY accept PayPal on eBay

selling, other payment is not acceptable.

Please PAY within 7 days, or we'll re-selling the item.

Shipping:

We ship to American via ePacket Delivery with tracking number;

We ship to Other countries/locations via International Economy Package with tracking number;

For shipping to The United Kingdom or Australia or Russian Federation, we strongly recommend you update to the

EUB(express);

Price for updating to the EUB(express):

For shipping to The United Kingdom or Australia: +5.99usd;

For shipping to Russian Federation: +3.99usd;

Shipping time:

10-20 working days for ePacket Delivery to the U.S.A.(normally you will receive it in about two weeks), depends on the

destination location;For other far locations may need more days.

Please note that International Economy Package can ship to the World wild with low price,but

the transport speed is very unstable,mail delay is very normal,shipping to far locations may

cost over 30 days,sometimes the cargoes will be stacked in the airport for over one month(especially in the special meeting time,it

happened before).

Please understand that we can't control the mail speed.If the mail delayed,please be patient.

If you wanna save your time,add extra money for updating to the EMS.

We ship to your PAYPAL Verified Address only;

Any import tax or charges should be paid by the buyer.

Tips:

About the Economy

Mail to the World Wide:

The International Economy Package is mailed to the destination country by CHINA POST and delivered via the local

postal system. Delivery time is usually between 14 to 30 business days.

Usually delivery status is traceable on the post office website of CHINA POST and(or) the destination country post office website.

Mail tracking

website:

But sometimes,on those web sites,you can track 0 info or just the info that when the goods are transported inside CHINA. Especially shipping to the far locations,just be patient.

For the Economy Mail,if we got the Tracking number for you,it means that the goods are

already in the post office.

If you have not received the goods in 30 days,notice us,we will ask for the detail tracking information

via the local post office.

Sun

02

Jun

2019

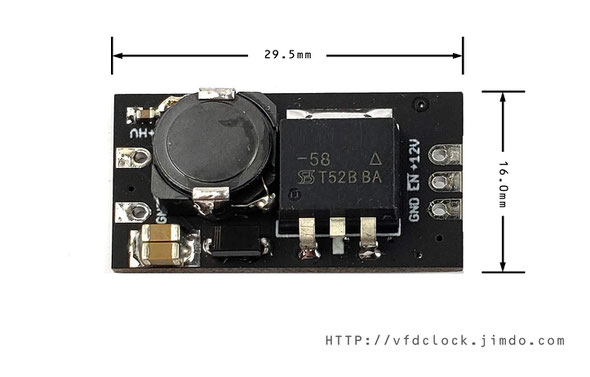

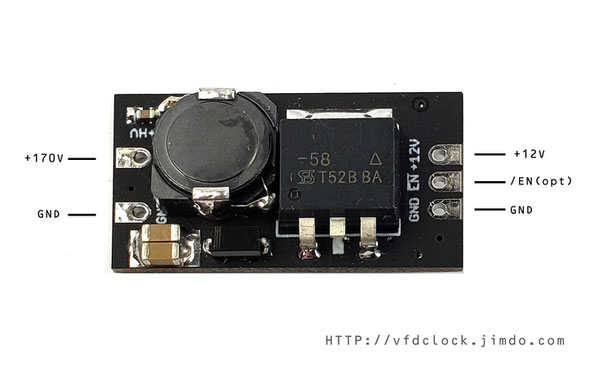

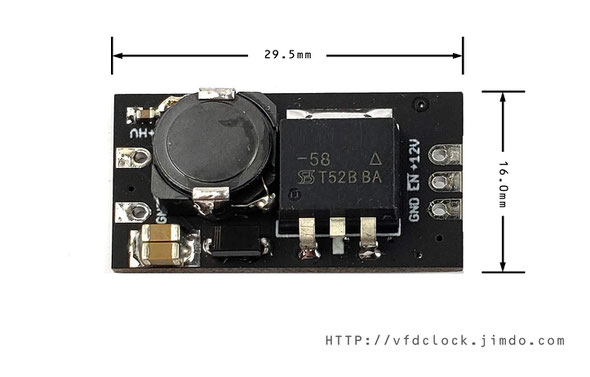

SLIM-8W-High Voltage Power Module-12Vto170V-MC34063-OpenHardware

Eagle source Files are inside the PDF file blow,please use Acrobat reader from adobe to open the PDF file,will find all files inside attach part of PDF. Others PDF reader may not be able to find the attached files inside PDF.

When save the attach file,Please rename the SLIM12D.rar.txt back to SLIM12D.rar, then open it with winrar.

You can find the password of PDF inside the parcel.

The Module can light up 6~8pcs IN-18 NIXIE tubes at the same time.

New-Slim 8W-34063 Based High Voltage for NIXIE

1.High efficiency,High power,up to 8W(Max);

2.Small size PCB,29.5mm(L)*16mm(W)*7mm(H) only;

3.Highly optimized circuit, high quality key components;

4.Open hardware design;

THIS MODULE CONTAINS DANGEROUS,

HIGH VOLTAGE POTENTIALS. USE CAUTION.

DO NOT TOUCH ANY PART OF THE MODULE WHEN IT IS WORKING.

Tips:

1. Please control the input current in <=0.8A for the low heat working state,if need more power output,you can increase the input voltage;

2. Please use high quality and stable input DC source,make sure no over the MAX input voltage;

3. Module contains input reverse polarity protection;

4. For the heavy loader,the max output voltage may get drop,it's normal;

5. Module contains an optional /EN pins to turn the module HV output ON/OFF,can be controlled by 3V3 or 5V mcu GPIO; when set this pin to H,will turn the module HV output off,when float or set to L,the module

will back to work;

Description:

This high voltage power converters are typical boost converters

based on 34063 chip which can accept 10 to 15V DC input,and output up to ~170V DC

.

We recommend work with 12Vin,and with <8W output;

Typical

Usage:

For driving NIXIE Tubes.

Typical Parameters:

(For reference only)

Input: 10V~15V DC, recommend 12V;

Output: ~170V DC;

Output

Current(MAX): 40mA;

Max Power

Intput: 8W;

Module size: 29.5mm(L)*16mm(W)*7mm(H); (~7mm height contains bottom equipment+PCB+top equipment

total).

Mon

20

May

2019

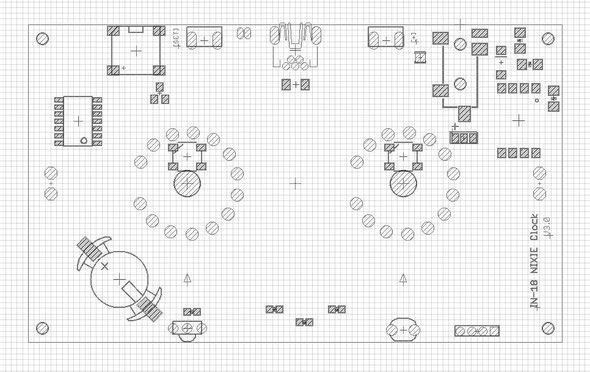

DIP-USB Powered-4-Tube-Arduino NIXIE Thermometer-Open Hardware

For assembling instructions,please check:

https://vfdclock.jimdo.com/2017/08/01/thermometer/

We add an extra IV-19 NIXIE tube to display [+]&[_]&[~],based on the 3-Tube NIXIE Thermometer design,others are all the same except the source code.

You can find the password of PDF inside the KIT BOX.

Please use Acrobat Reader from ADOBE to open the PDF in the page,or you may not be able to get the attached files inside the PDF if using other PDF reader!!!

Add-ons:

1mm grid of topside of PCB

Sun

19

May

2019

5V Ready-HL76W 5*7 dot char VFD display module for ARDUINO-5V Ready

Arduino Source code for ARDUINO UNO.

Compiled under ARDUINO V1.0.4 in pure C code.

Please use ACROBAT reader from Adobe to open the PDF file and find Source code files in attachments part of PDF.

Please use Acrobat Reader from ADOBE to open the PDF in the page,or you may not be able to get the attached files inside the PDF if using other PDF reader!!!

Specifications(For reference only)

VIN:5VDC/~250mA

Panel size: 110mm*21mm

PCB size: 120mm*30mm

Color: Green

Display:[5*7 dot] 13chars.

Driver Chip: PT6302

Features:

1).5V Ready, easy to be used. Can connect to your ARDUINO UNO board with only 3 singal wires;

2).High efficiency power circuit, no transformer, no heat, Low HV, very safe, High Brightness;

3).All SMT components, very thin PCB, easy to be drivered;

4).Contains over-current protection, and reverse connection

protection circuits;

5).Open source code for ARDUINO NUO, pure C code.

6).Simple 3-wire SPI interface, with EN pin, support shutdown the High Voltage and Filament Supply completely.

Interface:

3-wire SPI:

DIN

CLK

LATCH(CS)

+5V

GND

EN - High voltage & filament supply enable(optional)

(Tips:Some of the version may contain a test vias on PCB,just need to short the test 2pins then 5V poer on(please unconnect others pins) ,the module will do self testing.)

For video(s):

Sat

04

May

2019

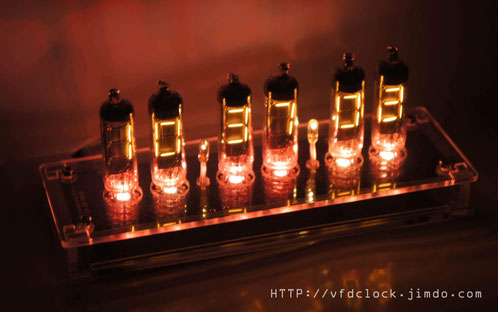

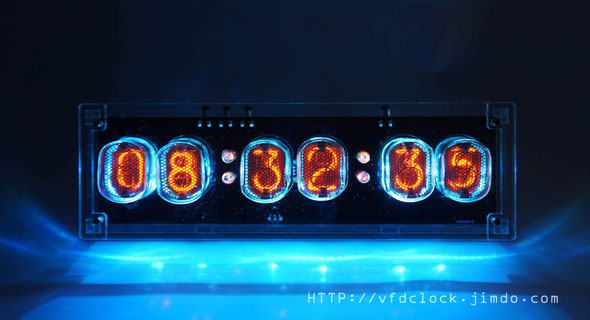

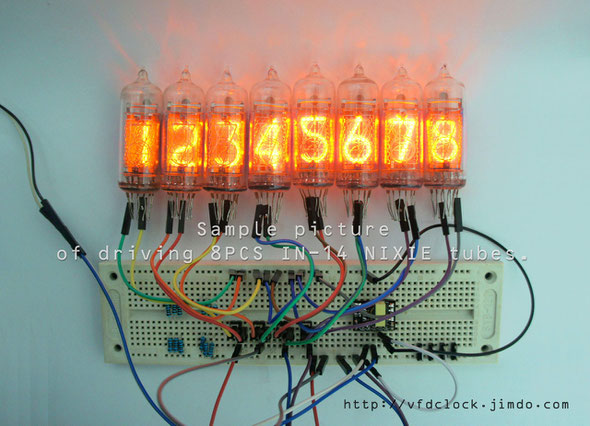

DIY KIT-5V USB Power-Pluggable IN-18 6-tube NIXIE clock-Assembly Instructions

5V USB Powered-IN-18 6-tube Clock DIY version

Assembly Instructions

V1.0

Notice

For assembling this NIXIE KIT you need to have the skill of soldering DIP& SMD components. We use a Hakko FX-888 Soldering Station (with CF2 Iron Head). We use 183℃(degree C)low melt

temperature solder wire S60, 0.5mm(Dia.), Brand Almit.And for most of the SMD components are big size and easy to be assembled,if you have a Hot air blower station,will help.

For how to solder the DIP components, we recommend:

https://www.hakko.com/english/tip_selection/type_bc_c.html

https://www.hakkousa.com/video/

For how to solder the SMD components, we recommend:

https://www.hakko.com/english/tip_selection/type_bc_c.html

https://www.hakkousa.com/video/

Please do not change any equipments of the KIT or you may not be able to get the KIT in working.

Because it most of SMD components are big size, so it is very easy for you to assemble, we recommend to check the circuit diagram carefully and follow the steps shown blow.

We do not recommend you to solder the components in random order or if it has problems you will need more time for de-soldering(*Will damage the PCB Pad) and debug, we recommend you follow the steps in this instructions that you can do part test after finished each step.

For more info & update, please visit HTTP://vfdclock.jimdo.com

Or contact us: zjjszhangf@gmail.com

Thanks for choosing our product.

Building it

Well, because of the circuit is block based and not very complicated, all you need to do is get all the components in the right position and make sure no short or no float before you plug

the power in. We will show the soldering steps blow.

Preparing

1. Please print out the PCB installation diagram by yourself, the Circuit diagram is no need for soldering job, print it or not depends on you(Note: May only have the paper circuit

diagram in the KIT with no digital version provide.);

2. Check all the components in the kit bag, make sure nothing is missing (You can do this on a A4 white copy paper);

3. We recommend using a soldering station and small soldering tip for soldering this kit (we use F2 or CF2 type tip). We recommend using ~180℃ type soldering tin for this job. Please do

not use the high temperature soldering tin in this project or you will damage components or the PCB;

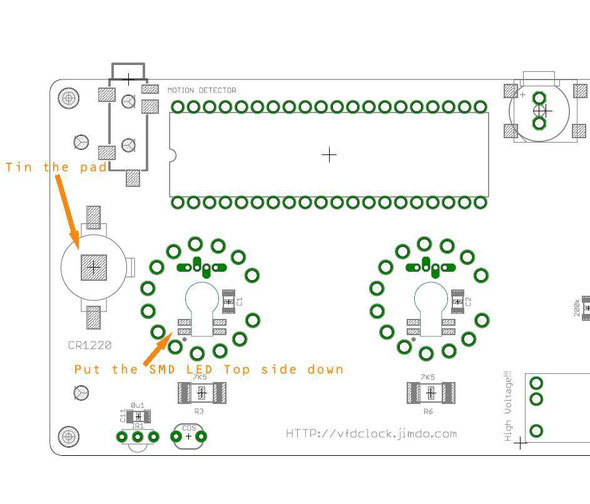

Please always remember that in this new version,only LEDs and NIXIE PINS and comma PINs are installing on the TOP side of PCB,others are all on the bottom side of PCB.

And double check the component before you solder it on PCB, and also double check its' direction for some diode and caps etc.,DO not go wrong,because of if go wrong,de-soldering DIP components are not very easy, may damage the PCB pad.

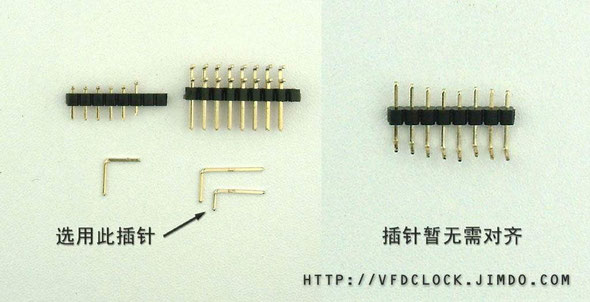

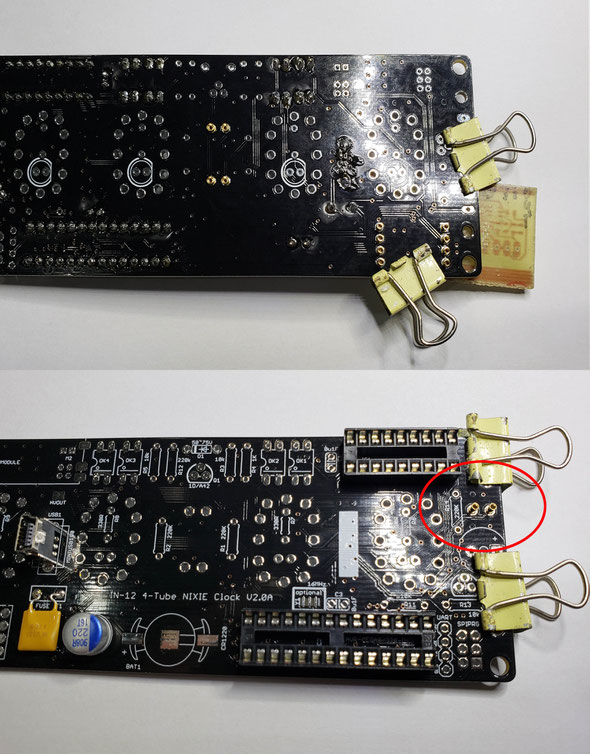

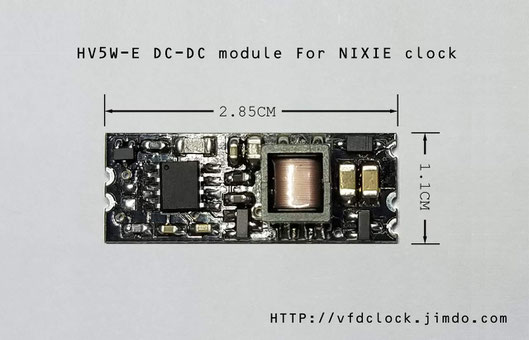

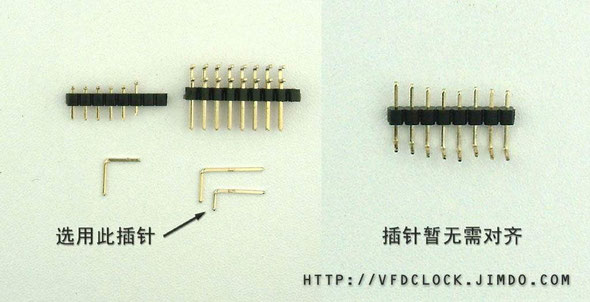

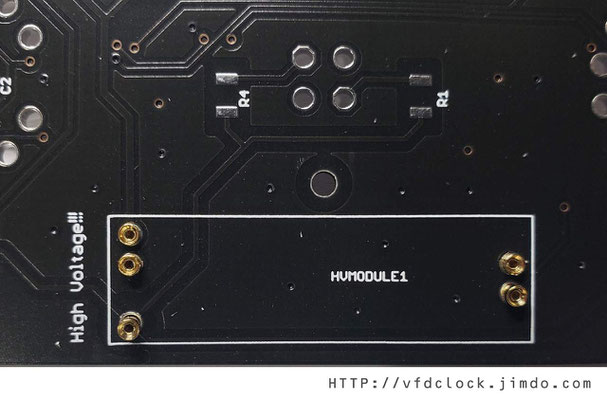

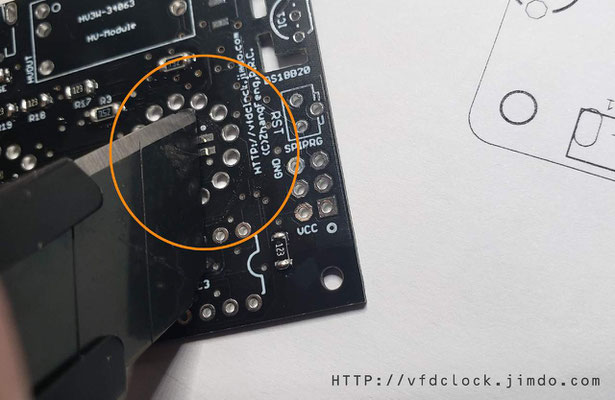

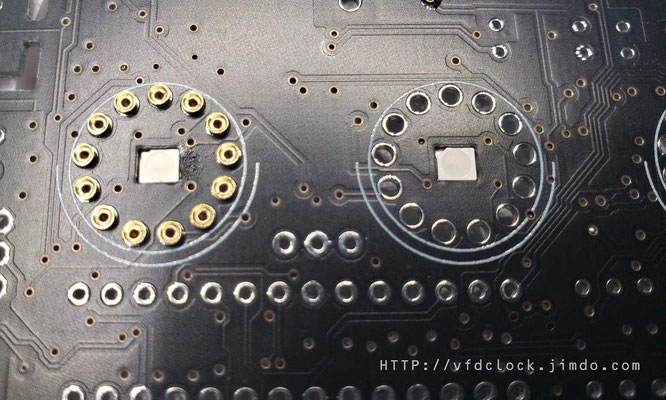

1): Middle comma Pins and HV module Pins

We need to solder some pins in this step,please solder it in this step,will be easier to be installed.

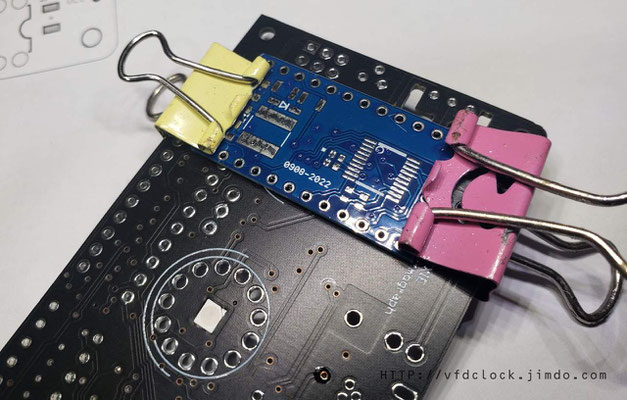

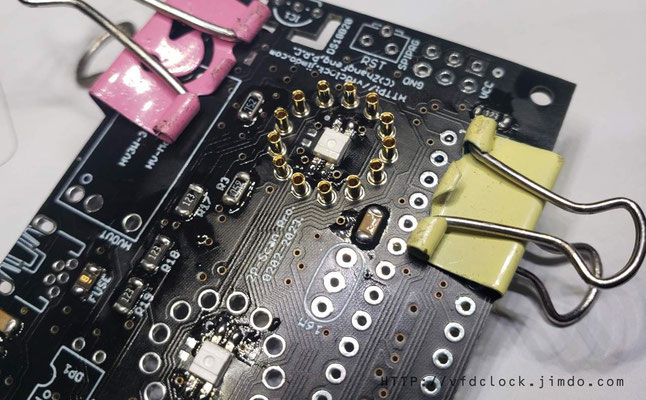

The first PINS are middle comma female pins,please plug the Female PINs on the top of the PCB then cover a had board like a small PCB or

small wood board etc.over the PINs, use two clamps to hold it with the main PCB, then flip the PCB. Now you can solder on the other side.

Tips: Because of the PINs are through hole version, please solder it carefully and do not let the tin goes in to the inside of the pins or will damage the PINs. If necessary, you can plug a

wood/bamboo toothpick in the bottom of PINs hole when soldering.

Test

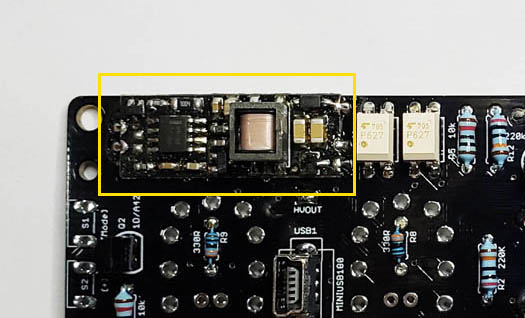

We have two types of HV moudles,for the SMD version ,you just need to solder it on the SMD PAD on the bottom side of PCB.

For the DIP version of HV moudle, we recommend you install it by using the female pins.